Evaporator of flake ice maker

A technology for evaporators and flake ice machines, which is applied in the direction of evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of reduced ice-making efficiency, shortened service life of evaporators, and uneven ice thickness. Easy to transport and install, long service life, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

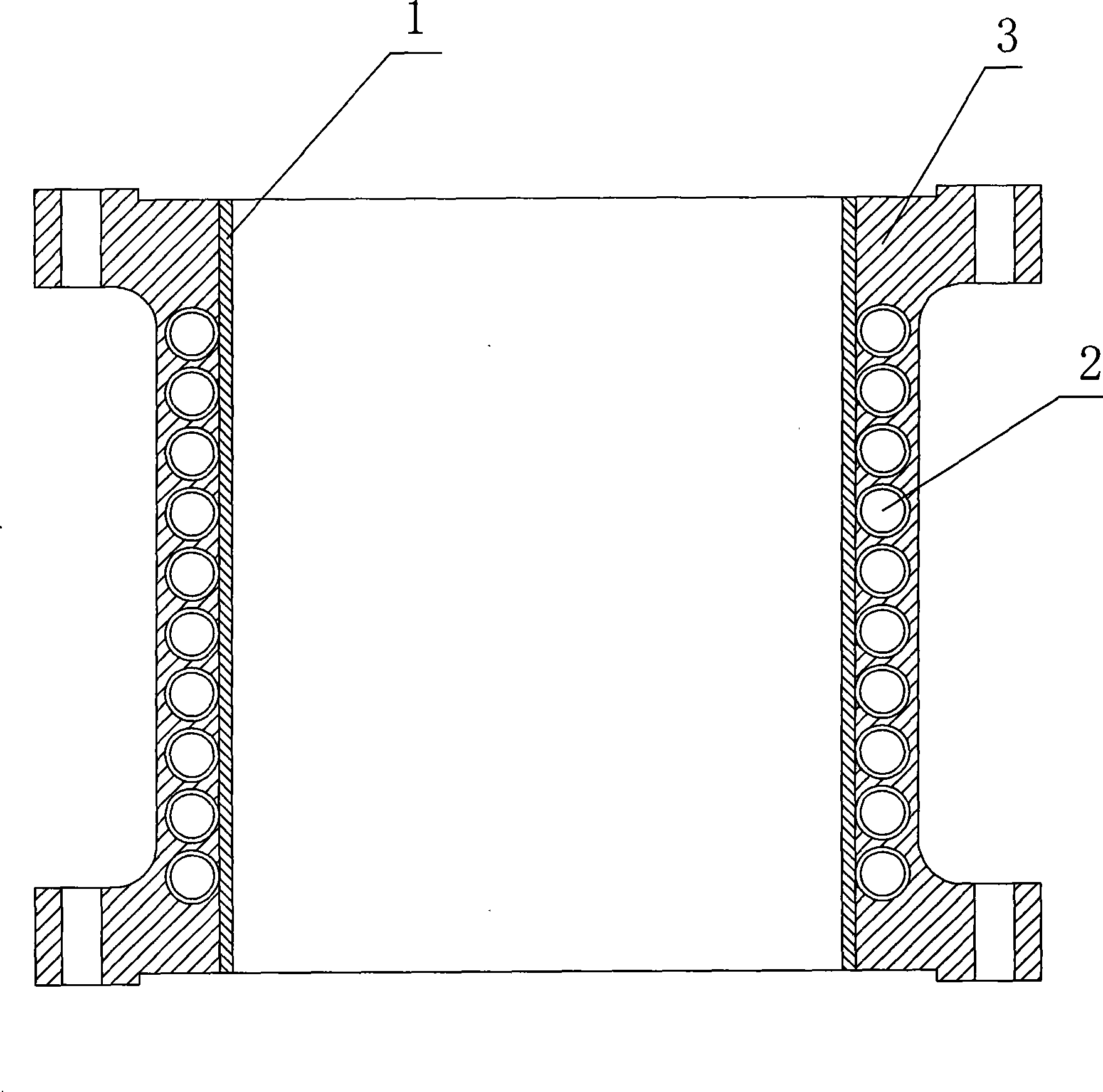

[0011] Accompanying drawing is the structure diagram of the present invention, as shown in the figure: the flake ice machine evaporator of the present invention comprises inner cylinder 1, refrigeration channel 2 and outer cylinder 3, and outer cylinder 3 is the casting layer of casting inner cylinder 1 outer wall, refrigeration The channel 2 is cast in the wall of the outer cylinder 3, the cooling channel 2 and the outer tube 3 are fixed by casting, the structure is firm, the cooling channel 2 has high pressure resistance, no leakage, and the surface is smooth after casting; Defects caused by welding of the spiral isolation plate and post-weld grinding work are adopted to avoid heat deformation of the inner cylinder 1 and the outer cylinder 2 during welding.

[0012] The refrigeration passage 2 in this embodiment adopts a spiral refrigeration coil structure. The spiral refrigeration coil is sleeved on the outer circle of the inner cylinder 1 and cast in the wall of the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com