Magnetoelasticity performance simultaneous on-line detecting method of iron magnetic thin film

A technology of ferromagnetic thin film and detection method, applied in the direction of material magnetic variables and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

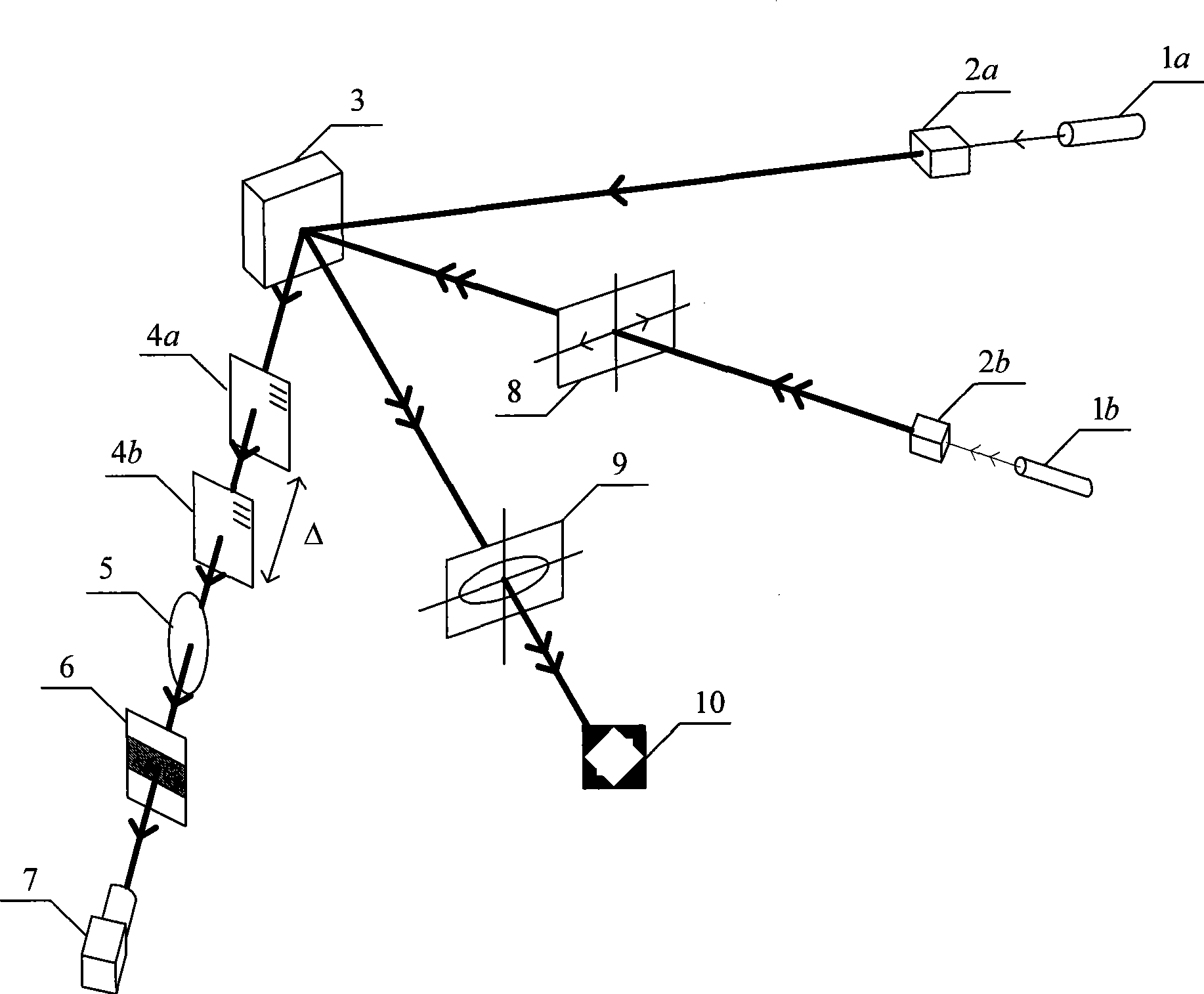

[0036] figure 1 It is the schematic diagram of the magnetoelastic property simultaneous on-line detection method of the ferromagnetic thin film of the present invention, in which the first laser 1a, the second laser 1b, the first beam expander 2a, the second beam expander 2b, the sample 3, the second beam expander 2b are included in the figure. A grating 4a, a second grating 4b, a lens 5, a filter screen 6, a CCD camera 7, a polarizer 8, an analyzer 9, and a photodetector 10.

[0037] The first laser 1a, the first beam expander 2a, the first grating 4a, the second grating 4b, the lens 5, the filter screen 6, and the CCD camera 7 constitute a film non-uniform stress measurement optical path, and the first laser 1a emits The laser light reaches the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com