Directly-coupling cup-shaped microwave energy-feeding antenna and array microwave heater thereof

A technology of a microwave heating device and an energy-feeding antenna, which is applied to microwave heating and other directions, can solve the problems of high cost, low efficiency, and uneven heating of the microwave heating device, and achieves the effects of compact structure, high efficiency, and improved heating uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

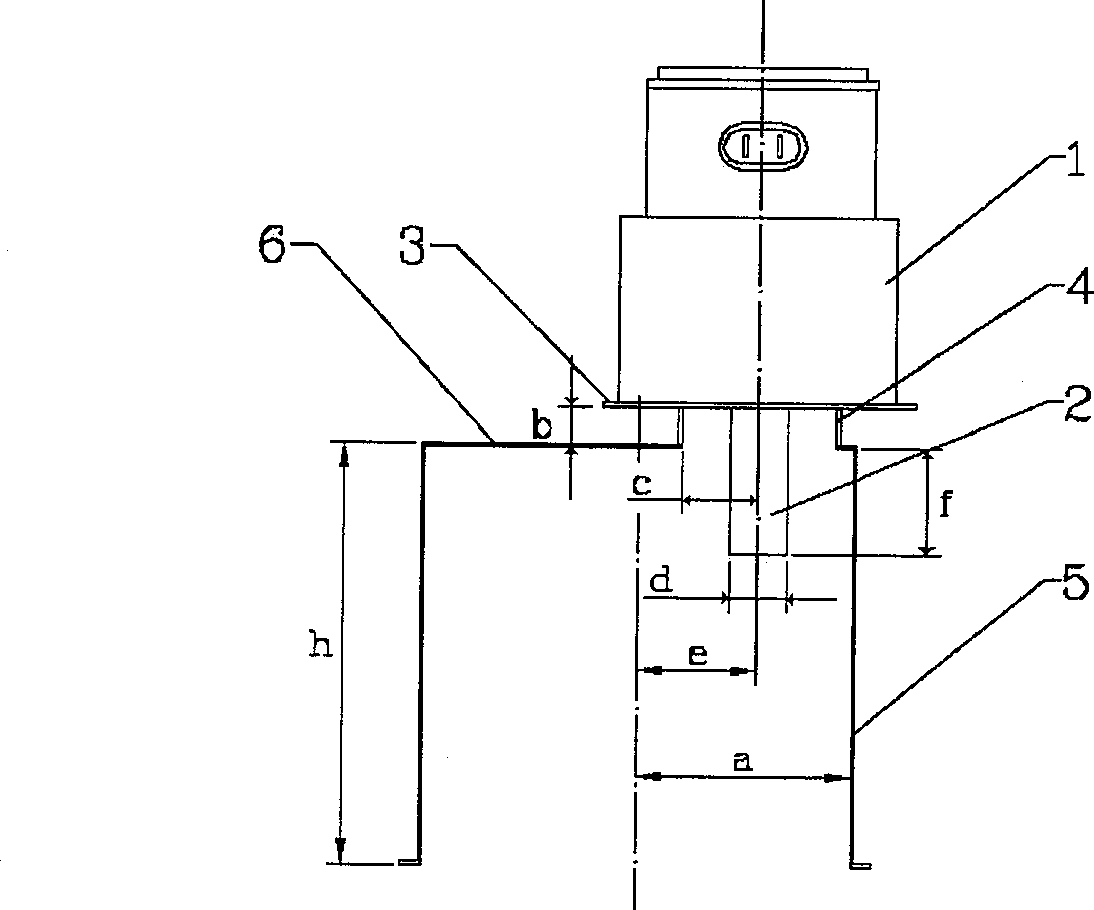

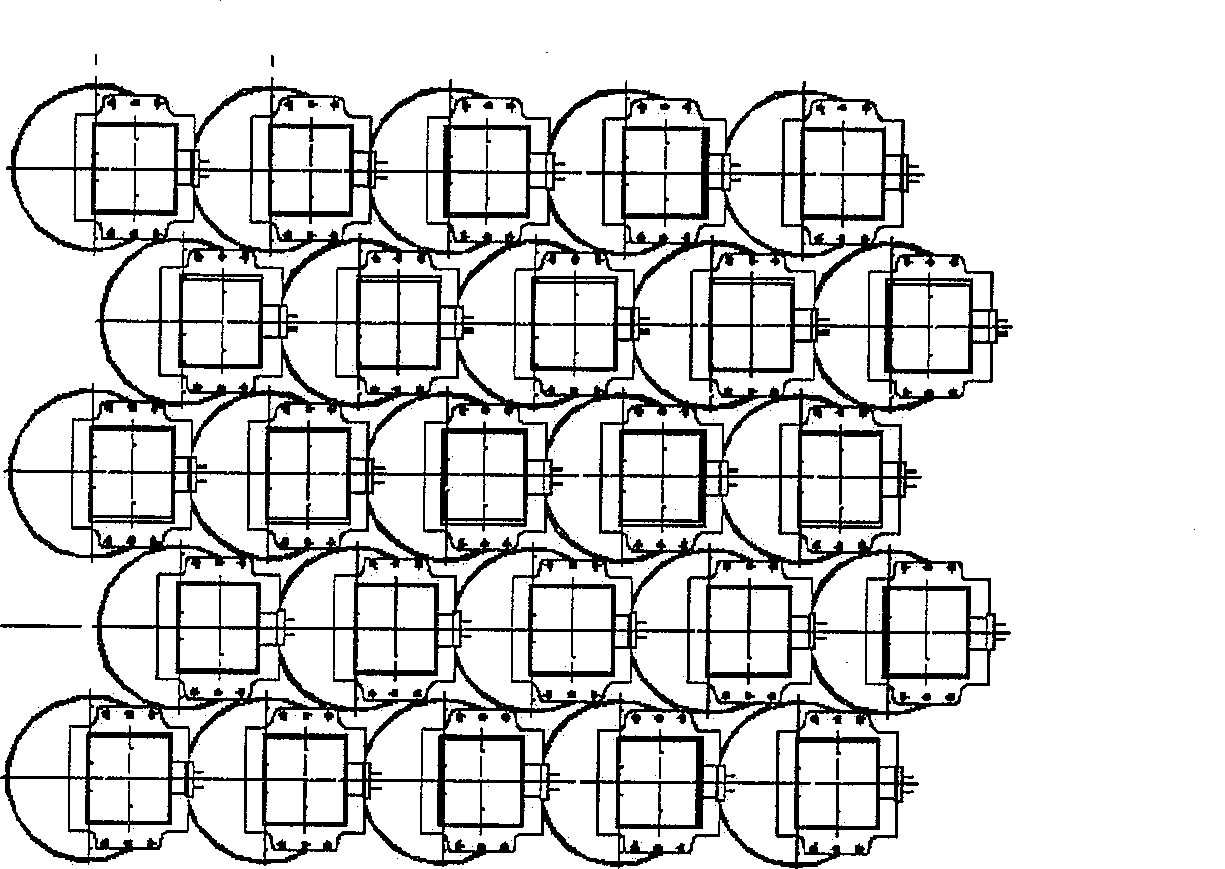

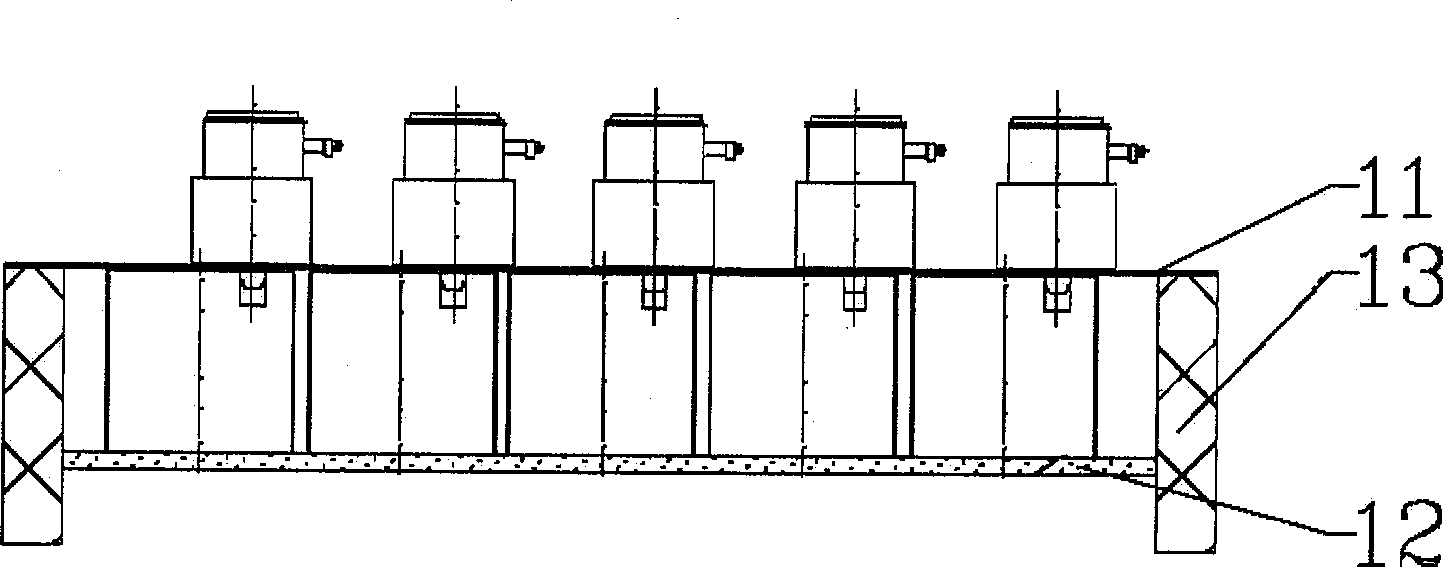

[0020] Attached below figure 1 figure 2 and image 3 The embodiment of the present invention will be further described.

[0021] This implementation case is designed according to the operating frequency of the microwave source is 2.45GHz. The direct-coupled cup-shaped microwave feeding antenna is made of stainless steel. It has good chemical stability in harsh environments such as volatiles, high mechanical strength, and is easy to process and install. Moreover, the entire surface area of the cup-shaped cylinder is small, and the absorption of microwaves can be ignored. The radius a of the cup-shaped antenna cylinder 5 is 60 to 62 mm, and the height h is 120 to 123 mm; the inner radius c of the output coaxial line section 4 is 17.5 mm; the inner conductor of the coaxial line, that is, the diameter d of the magnetron output antenna head 2 is 17mm, the eccentricity e of the cup-shaped antenna cylinder 5 and the output antenna head 2 is 30mm, the insertion depth f of the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com