Die-forming process of bamboo particles used for packaging materials and die for hot-press forming thereby

A packaging material and production process technology, applied in the field of hot press molding molds, can solve the problems of affecting the quality of the board, difficult to control the moisture content, and the reduction of the bonding strength of the board, so as to achieve the effect of convenient operation and easy realization of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is a kind of bamboo scrap molding production technique for packing material, comprises the following steps:

[0024] (1) Bamboo shavings or the residue of processing are dried until the moisture content is lower than 25%;

[0025] (2) stirring the urea-formaldehyde resin, starch, moisture-proofing agent and release agent with a solid content of 50% and spraying the dried bamboo scraps, the sizing amount is 12-15%;

[0026] (3) dry the raw materials mixed with glue again, and dry to below 20%;

[0027] (4) Pave the dried raw materials;

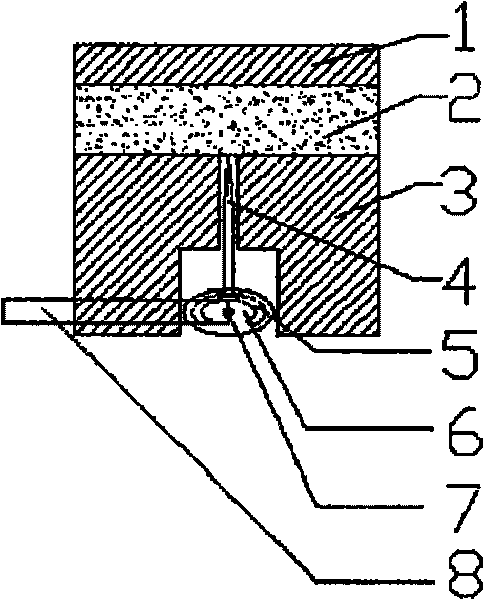

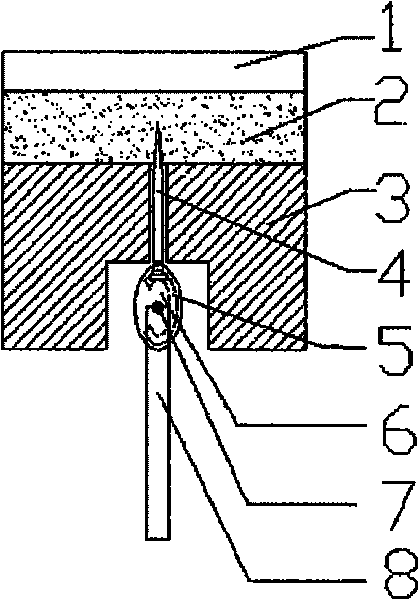

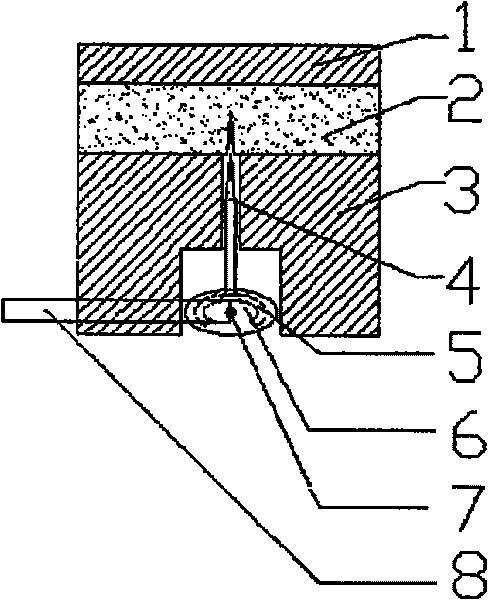

[0028] (5) Spread the weighed raw materials on the mold, and finally use a high temperature of 140-180°C and a pressure of 10-80kgf / cm2 to perform hot-press molding. The best time for acupuncture is to use the thimble to pierce the slab after pressing and heating for tens of seconds. The gas in the slab gradually overflows, because the slab is a flat plate, in order to make the slab ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com