Split type micro-electric mechanic system and preparation method thereof

A micro-electromechanical system, split technology, applied in the field of micro-machining, can solve the problems of the chip cannot be reused, the chip operation cost is high, and has no practicability, so as to ensure light transmittance and surface biochemical characteristics, suitable for one-time use. Useful, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The split micro-electromechanical system and its preparation method proposed by the present invention are described as follows with reference to the drawings and embodiments.

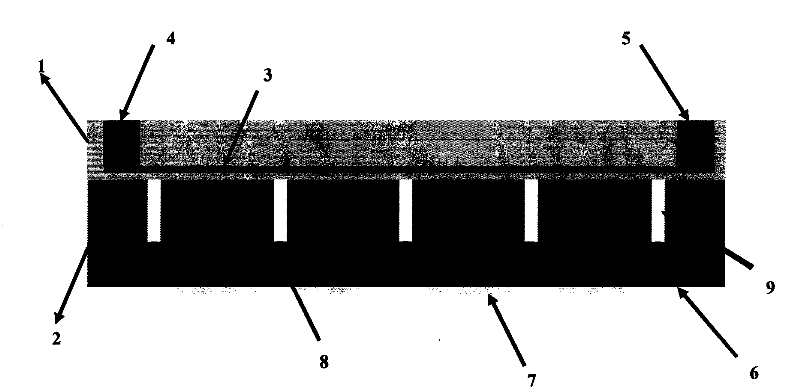

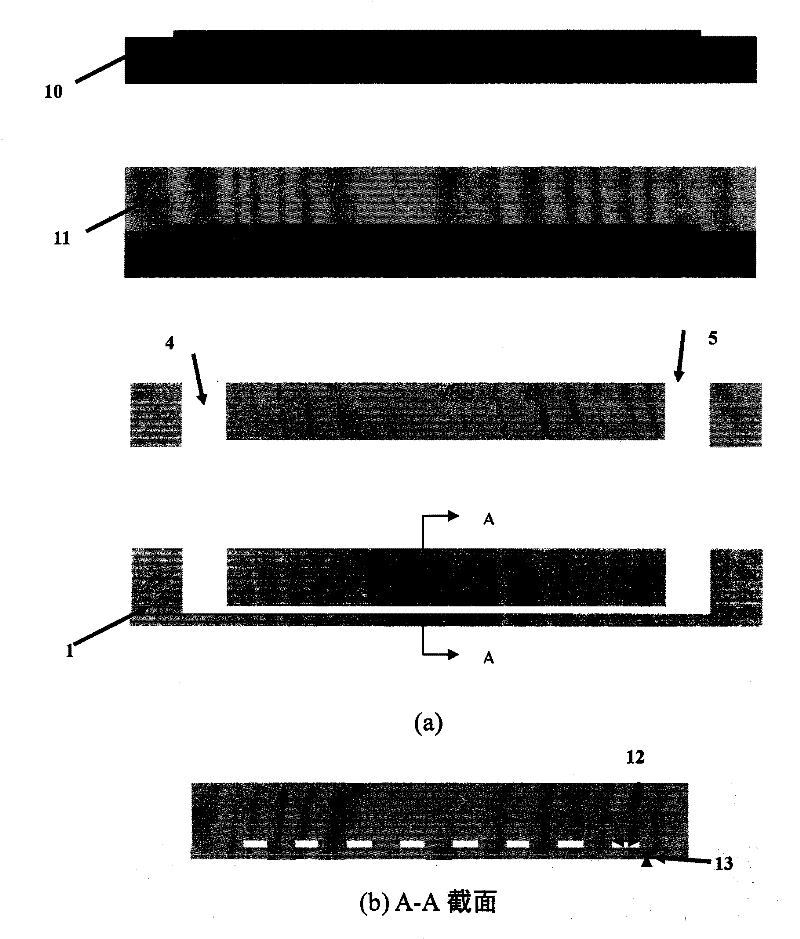

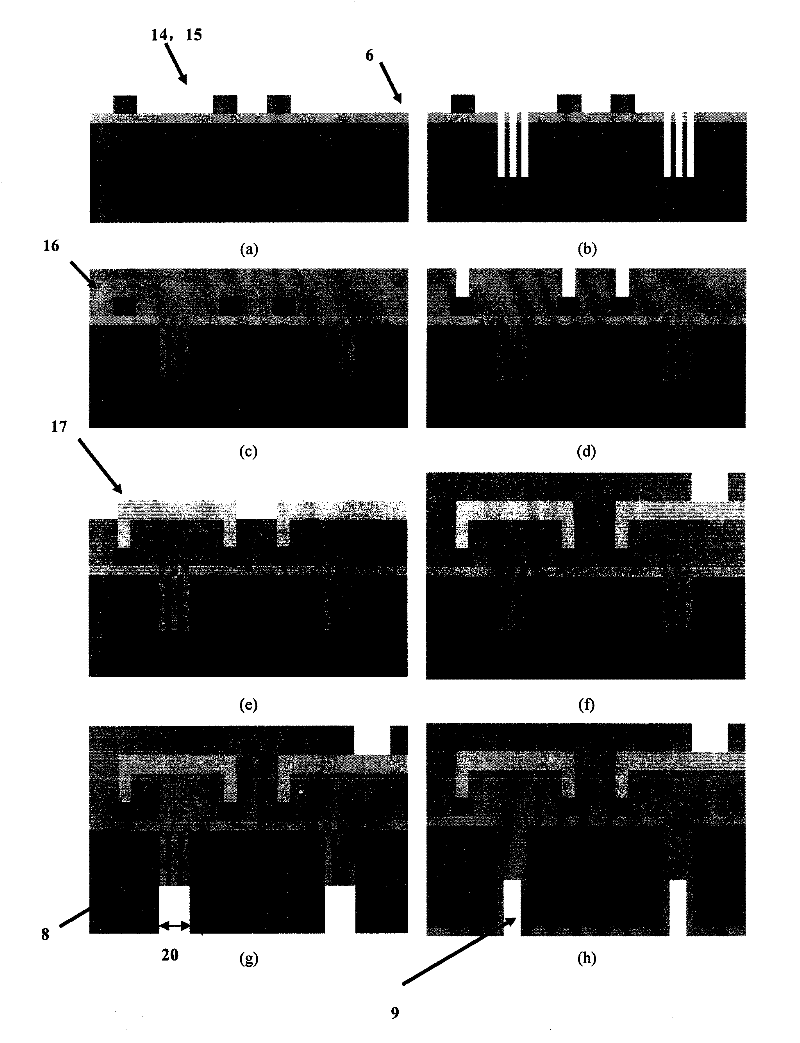

[0020] The embodiment of the split MEMS system of the present invention figure 1 As shown, the system includes: a microfluidic chip 1 made of polydimethylsiloxane, the thickness of which is about 2-3 mm, the microfluidic chip 1 contains a sample channel 3 to be detected and analyzed, and the channel The width 12 is 200 μm, the thickness 13 is 50 μm, and the length direction is serpentine arrangement, with a total length of 2 m; the connection between the concave channel and the microfluidic chip has two openings 4, 5 with a diameter of 1 mm; The functional substrate 2 includes: a silicon dioxide insulating layer 6 formed on the inner surface of the bottom of the functional substrate, the thickness of which is 3000 A plurality of parylene connection structures 8 and air gap structures 9 uniformly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com