Direct everbright fast orange GGL pollution-free preparation process

A preparation process, pollution-free technology, applied in the preparation of azo dyes, azo dyes, organic dyes, etc., can solve the problem of high processing costs, achieve the effects of increased yield, reduced raw material costs, and simplified procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

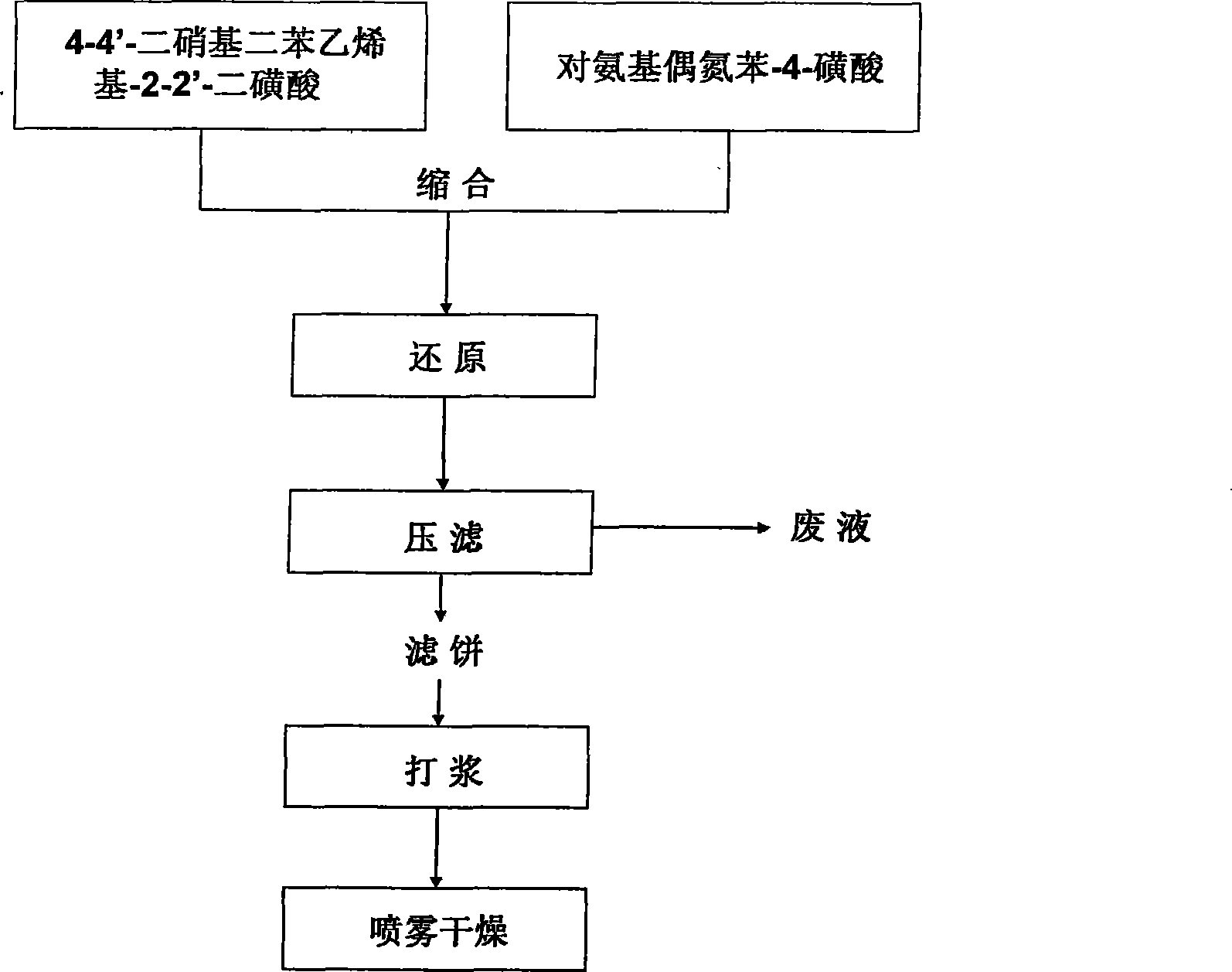

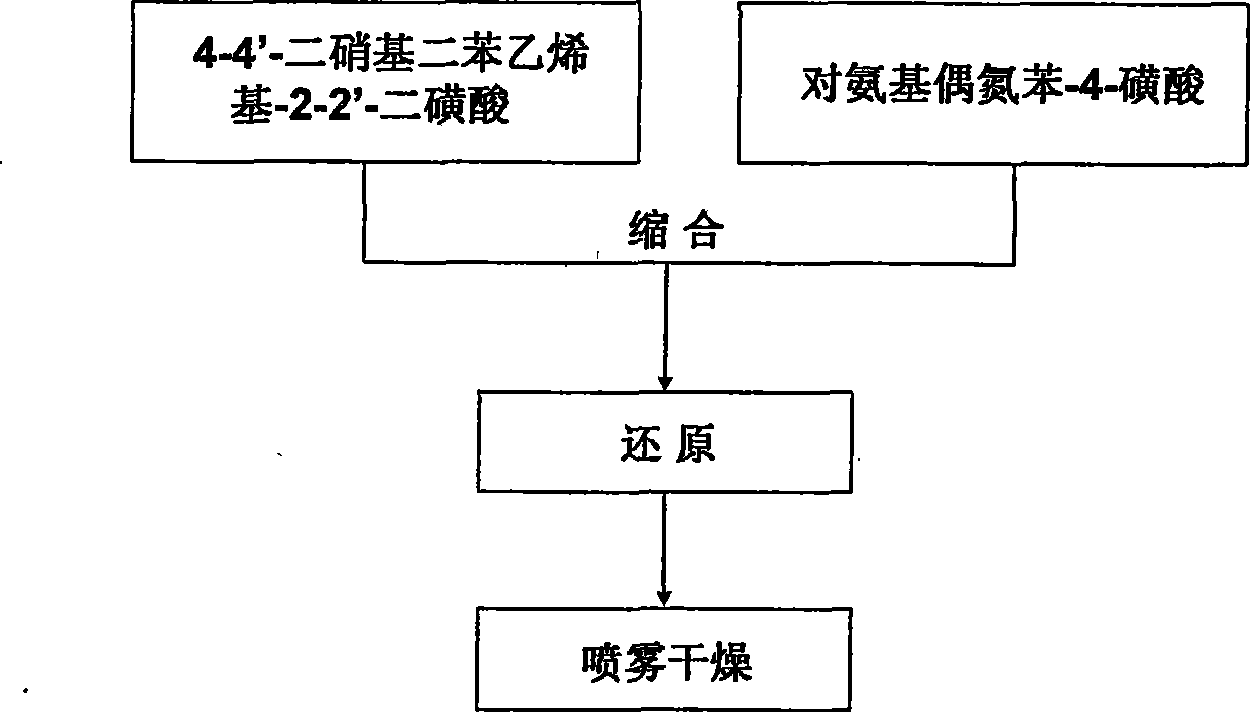

[0018] In the following, in conjunction with the accompanying drawings and preferred embodiments, the specific implementation and features provided according to the present invention are described in detail as follows:

[0019] Such as figure 2 As shown, a direct light fast orange GGL non-polluting preparation process is characterized in that the implementation steps include:

[0020] (1) Condensation:

[0021] In the condensation reactor, first add 23500L-24000L of water, then add 1290kg of p-aminoazobenzene-4-sulfonic acid with a purity of 100% and 4-4'-dinitrostilbene-2 with a purity of 100%. 790kg of -2'-disulfonic acid, stirring and beating for 30-40 minutes, then slowly add sodium hydroxide in batches to adjust the pH=7.5-8, then add 800Kg of sodium hydroxide, open the steam inlet valve for 1 to 1.5 hours The internal temperature is raised rapidly to t=100~102℃, pH=13~13.5 detected with acidity meter, and the temperature is controlled to continue stirring for 12~12.5 hours...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap