Auxiliary addition agent of burner

A technology of auxiliary additives and burners, applied in the direction of fuel, solid fuel, petroleum industry, etc., can solve the problems of reducing combustion efficiency, slow, and accelerated combustion effects, etc.

Inactive Publication Date: 2009-06-03

NAT CHENG KUNG UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Generally speaking, when any substance burns (especially solid substances are more significant), it starts to burn from the surface of the substance, and gradually burns into the interior of the substance as the temperature increases; however, often due to the oxygen contained in the substance Insufficient amount and inability to effectively directly contact external oxygen, in addition to slow combustion reaction, at the same time, it is easy to reduce combustion efficiency due to incomplete combustion of the substance, and even promote a large amount of pollutants generated by combustion, causing air pollution

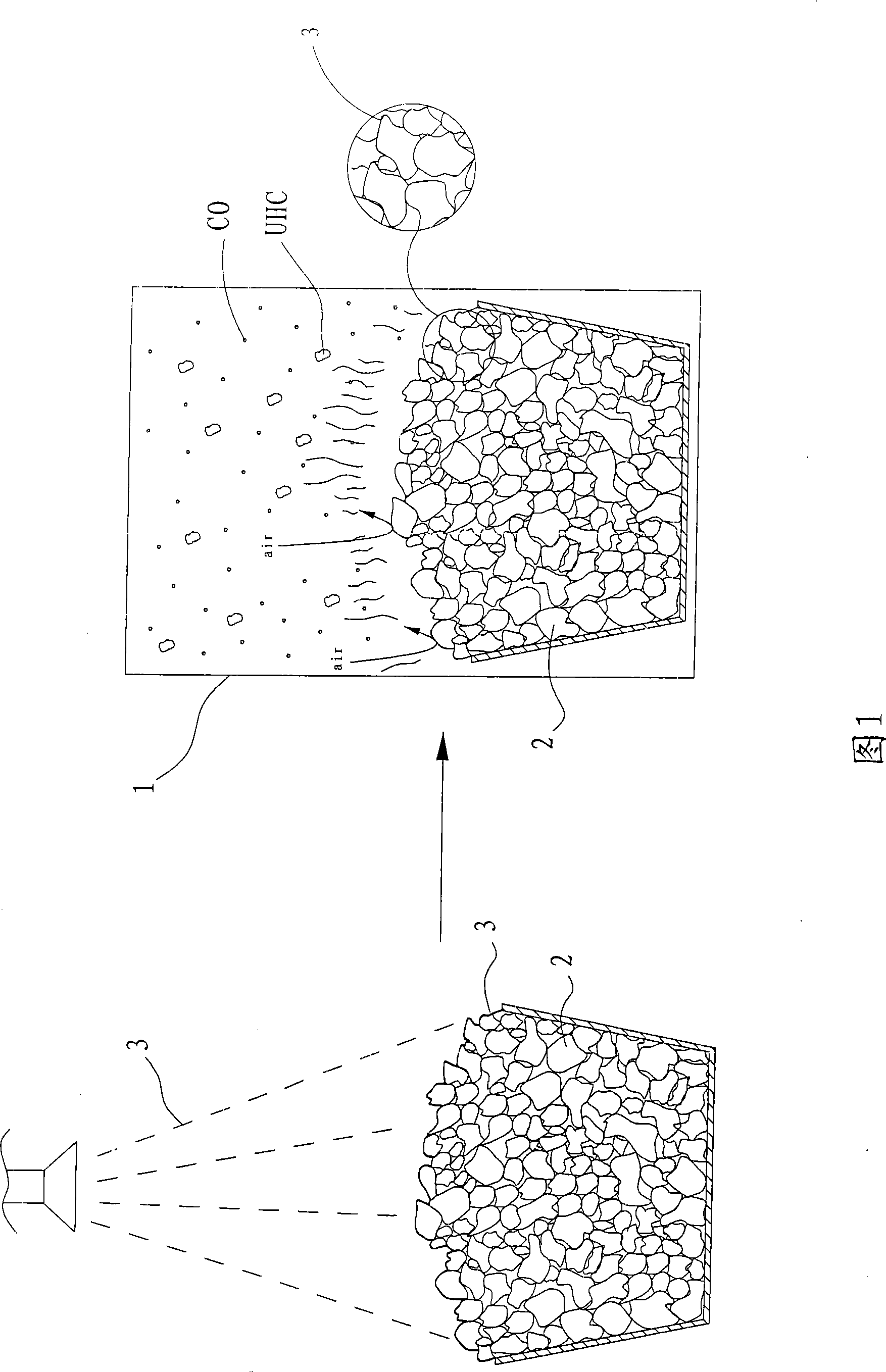

[0004] Referring to Figure 1, taking the operation of burning garbage 2 in the general incinerator 1 as an example, pour the garbage 2 into the incinerator 1, and wait until the garbage 2 is piled up to a certain amount before starting the combustion operation. Therefore, during the combustion process, both Rely on the surface of garbage 2 to carry out pyrolysis or surface combustion reaction. For garbage 2 stacked in the middle and lower layers, no combustion reaction can occur. Incomplete, and then produce carbon monoxide (CO), unburn

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

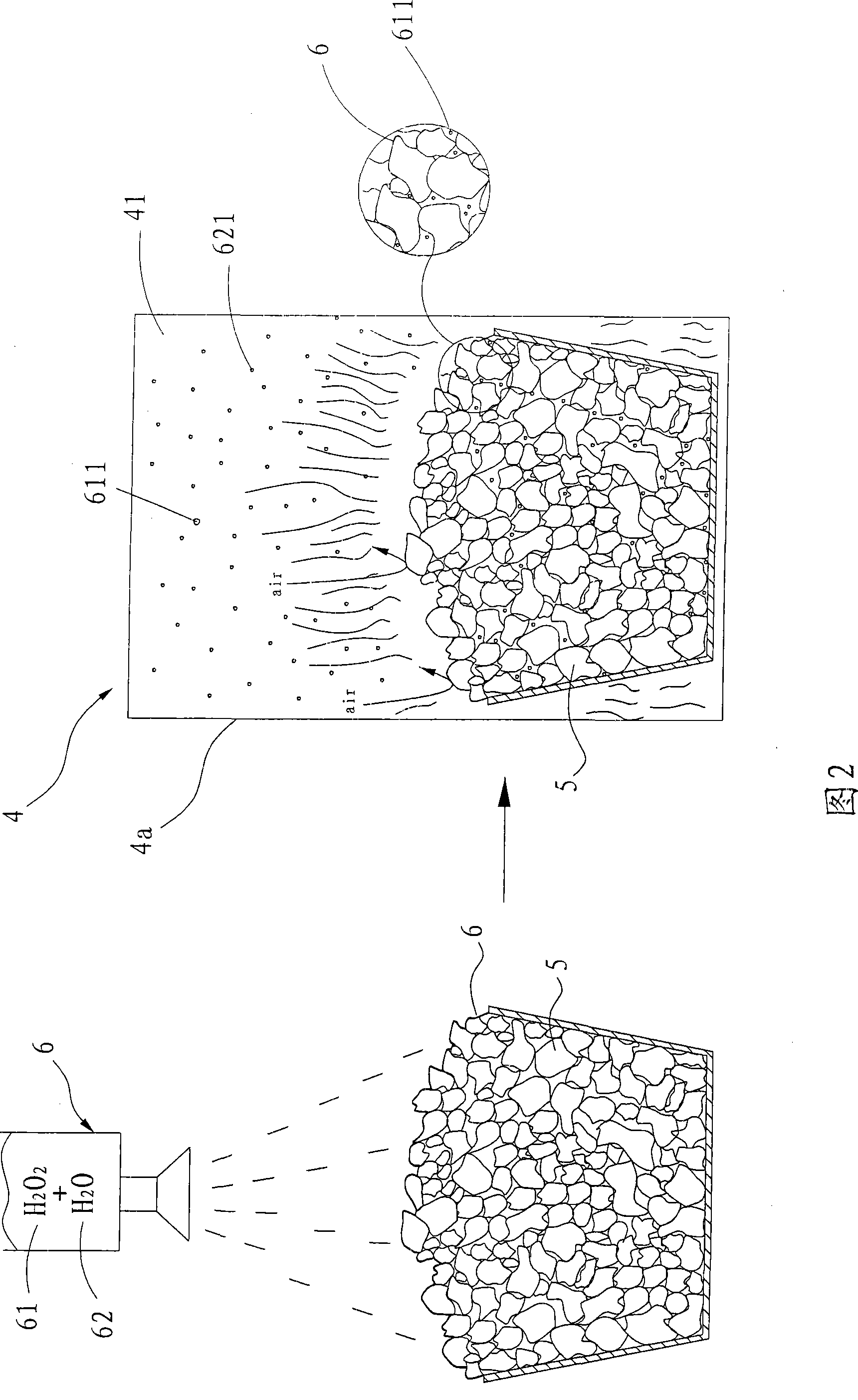

The invention discloses an auxiliary addition agent of a burner. The auxiliary addition agent comprises a liquid mixture which is mixed by peroxide and water by the following weight percentage; wherein, the addition proportion of the peroxide is 30 to 100 percent; the addition property of the water is 0 to 70 percent; the auxiliary addition agent is added into the burner, affected by heating and catalyzing to generate pyrolysis and then converted into hot steams and gox; the high oxidation capacity thereof can accelerate the burning speed of a substance to be burnt in the burner, thereby not only leading the substance to be burnt and fuels to be burnt more completely, but also improving the burning benefit of the fuels; the oxidation capacity can effectively reduce the generation of carbon monoxide and non-burnt hydrocarbon, and reduce the exhaust of burning contaminations.

Description

technical field [0001] The invention relates to an auxiliary agent, in particular to an auxiliary agent for a burner which can effectively improve the combustion efficiency of fuel and effectively reduce the emission of combustion pollutants. Background technique [0002] Burners (such as common boilers, incinerators, etc.) are widely used in industry to generate energy or eliminate waste, and the steam and hot water generated after combustion can be used in power generation, steam-electric cogeneration, industrial processes and heating systems etc.; in recent years, as fuel prices have been increasing day by day, and the issues of greenhouse effect and environmental damage have been widely discussed, how to effectively improve fuel saving effects, improve combustion efficiency, and reduce combustion pollution has become an important issue nowadays. The goal of public effort. [0003] Generally speaking, when any substance burns (especially solid substances are more signifi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L9/12

Inventor 赵怡钦陈冠邦吴志勇许纮玮陈志鹏

Owner NAT CHENG KUNG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com