Environment-friendly type gas-charging compound material and production method thereof

An inflatable material, an environmentally friendly technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of cost increase, loss of light, discoloration, etc., achieve large social and economic benefits, and small permanent deformation , low creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

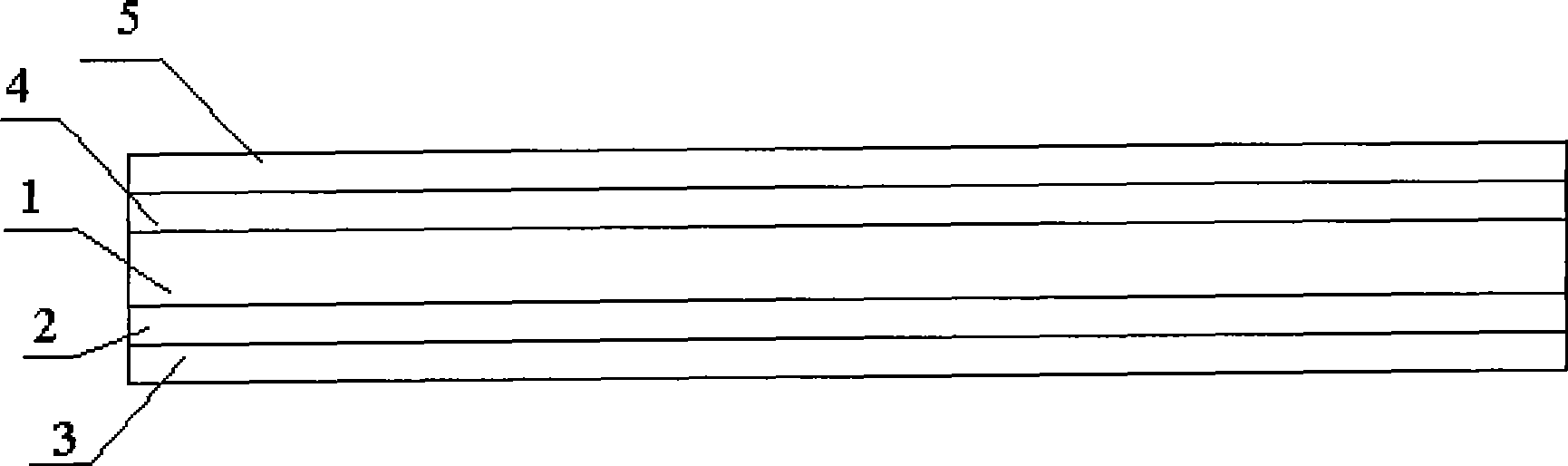

[0057] prepared as figure 1 Environmentally friendly composite inflatable material shown.

[0058] The coating amount of the back primer layer is 80g / m 2 ;

[0059] The coating amount of the front primer layer is 80g / m 2 ;

[0060] The coating amount of the back surface coating is 280g / m 2 ;

[0061] The coating amount of the front surface coating is 300g / m 2 ;

[0062] formula:

[0063] Components and parts by weight of the material of said back primer coat and front primer coat are:

[0064] Paste polyvinyl chloride resin (EPVC) 100 parts

[0065] Stabilizer 5 parts

[0066] Plasticizer 70 parts

[0067] Filler 20 parts

[0068] Lubricant 0.5 parts

[0069] Components and parts by weight of the material of said back surface coating and front surface coating include:

[0070] Powdered polyvinyl chloride resin (SPVC) 100 parts

[0071] Stabilizer 2 parts

[0072] 2 parts processing aid

[0073] Plasticizer 50 parts

[0074] Filler 20 parts

[0075] Lubricant 0...

Embodiment 2

[0102] prepared as figure 1 Environmentally friendly composite inflatable material shown.

[0103] The coating amount of the back primer layer is 50g / m 2 ;

[0104] The coating amount of the front primer layer is 50g / m 2 ;

[0105] The coating amount of the back surface coating is 180g / m 2 ;

[0106] The coating amount of the front surface coating is 180g / m 2 ;

[0107] formula:

[0108] Components and parts by weight of the material of said back primer coat and front primer coat are:

[0109] Paste polyvinyl chloride resin (EPVC) 100 parts

[0110] Stabilizer 2 parts

[0111] Plasticizer 80 parts

[0112] Filler 10 parts

[0113] Lubricant 1.5 parts

[0114] Components and parts by weight of the material of said back surface coating and front surface coating include:

[0115] Powdered polyvinyl chloride resin (SPVC) 100 parts

[0116] Stabilizer 5 parts

[0117] 1 part processing aid

[0118] Plasticizer 70 parts

[0119] Filler 10 parts

[0120] Lubricant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com