Installation and closure construction method for steel sliding roadway arch on top surface of steel trussed beam bridge

A technology for steel truss girder bridges and roofs, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult construction, high specification requirements, and difficult construction of construction platforms, and achieve the effect of great promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

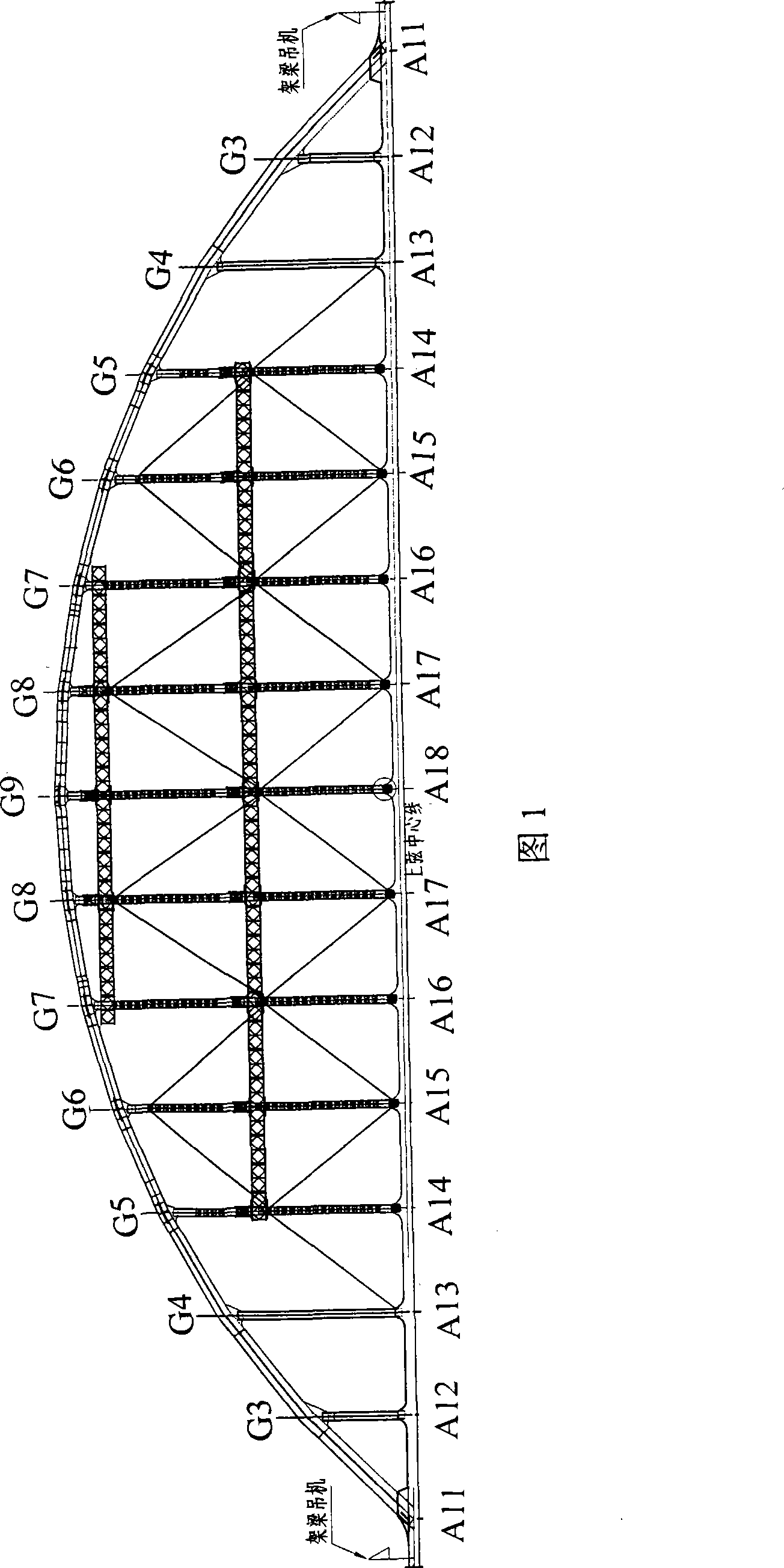

Image

Examples

Embodiment Construction

[0014] The present invention comprises following processing steps:

[0015] (1) After the steel truss girder is closed, adjust the position of the center line of the steel girder and the elevation of each support, and at the same time pre-assemble the arch girder, then transport it to the wharf with a flatbed truck, hoist it on the iron barge by the wharf crane, and transport it by water to the erection specific area.

[0016] (2) Two 80t girder erecting cranes lift the lower suspender from the iron barge at the same time, install it on the mid-span node of the steel truss girder, immediately install the vertical and horizontal Bailey beams, and install the cable-stayed equipment in time.

[0017] (3) Lift the upper boom and connect it with the lower boom through punching nails and high bolts. Also install Bailey beam couplings and cable-stayed equipment on the upper boom, and install arch ribs and arch joints after stabilization.

[0018] (4) After the two arches in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com