Liquid crystal display device, array substrate and method for repairing defects thereof

A technology for liquid crystal display devices and array substrates, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low production yield, and achieve the effects of improving yield, improving performance, and avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

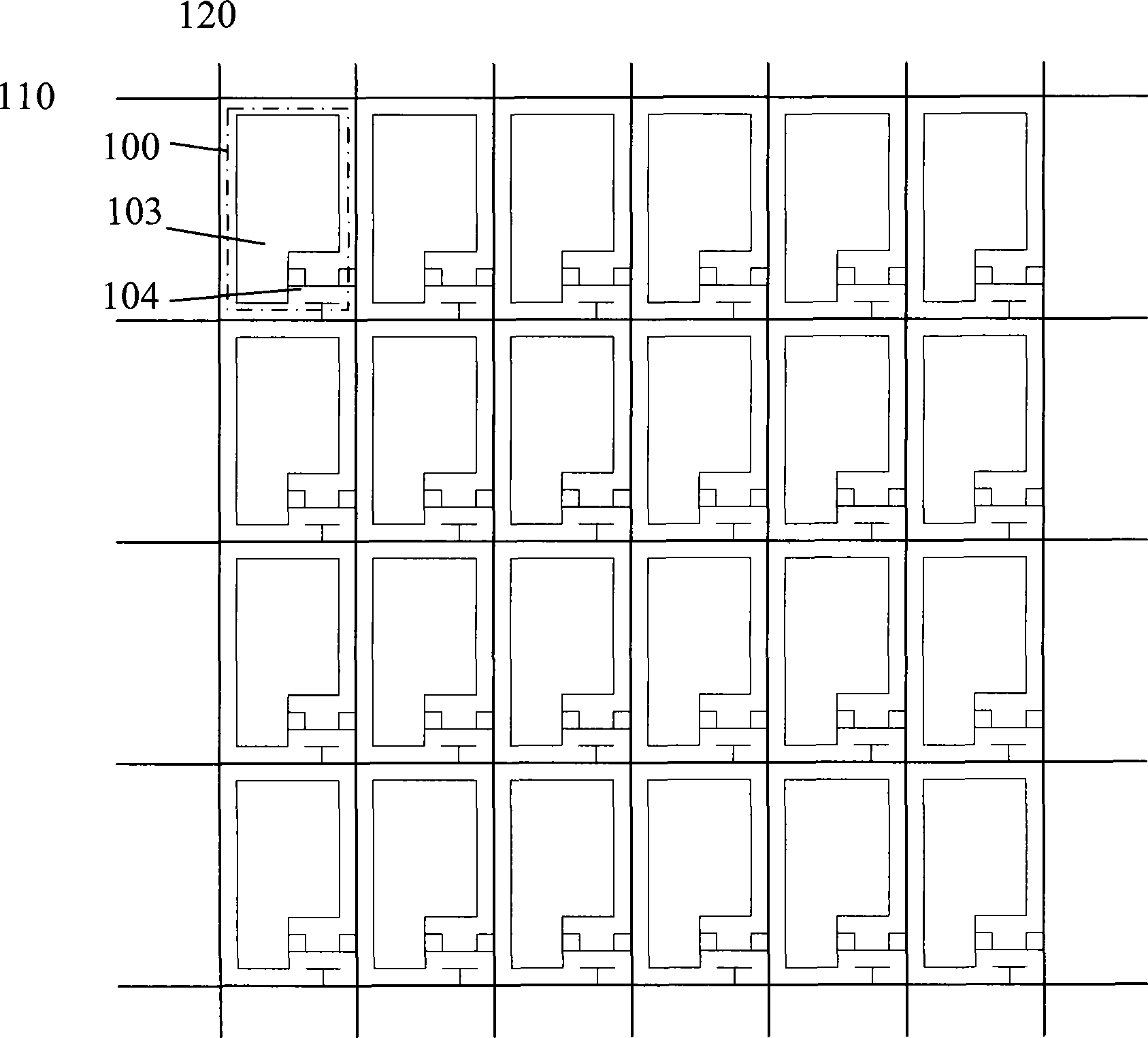

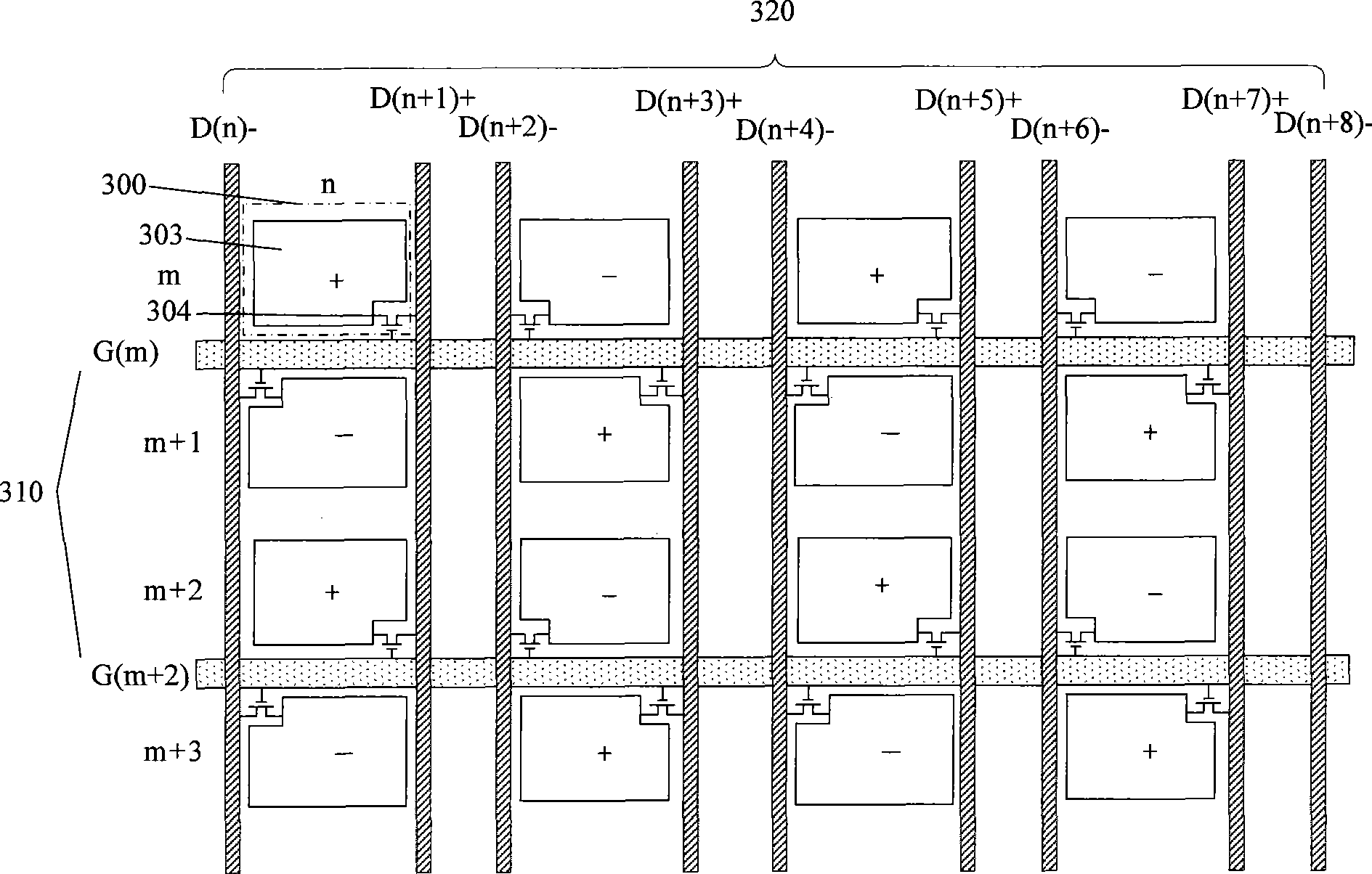

[0050] Figure 4 It is a schematic diagram of the array substrate of the liquid crystal display device in the first embodiment of the present invention, such as Figure 4 As shown, the array substrate includes scan lines 410 , data lines 420 arranged across the scan lines 410 , pixel units 400 , pixel electrodes 403 and transistors 404 disposed in the pixel units 400 .

[0051] Among them, its scan line 410 (including Figure 4 G(m) and G(m+2) shown in ) and data line 420 (including Figure 4 D(n), D(n+1)...etc. shown in image 3 The same as shown in , and will not be repeated here.

[0052] Such as Figure 4 As shown, the array substrate also includes a first repair line 451 and a second repair line 452 located in different layers, and the first repair line 451 is also in a different layer from the data line 420, and the second repair line 452 It also has a different layer from the scan line 410 . In this embodiment, for the convenience of manufacture, the first repair ...

no. 2 example

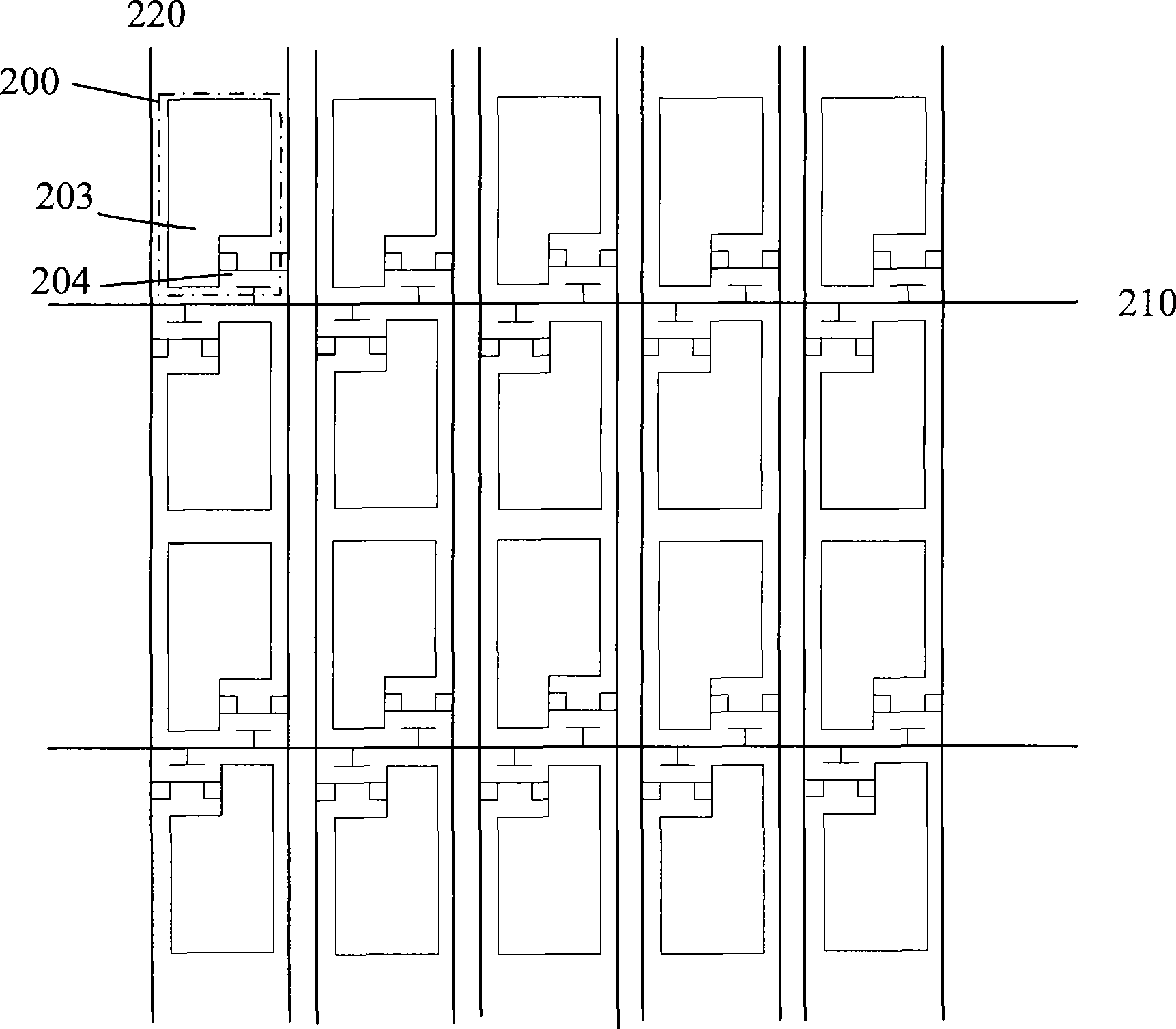

[0060] Figure 5 It is a schematic diagram of the array substrate of the liquid crystal display device in the second embodiment of the present invention, such as Figure 5 As shown, the array substrate includes scan lines 510 , data lines 520 arranged across the scan lines 510 , pixel units 500 , pixel electrodes 503 and transistors 504 disposed in the pixel units 500 .

[0061] Among them, its scan line 510 (including Figure 5 G(m) and G(m+2) shown in ) and data line 520 (including Figure 5 D(n), D(n+1)...etc. shown in ) and each pixel unit 500 are connected with Figure 5 The same as shown in , and will not be repeated here.

[0062] Such as Figure 5 As shown, the array substrate further includes a first repair line 551 and a second repair line 552 located in different layers. Preferably, the first repair line 551 and the scanning line 510 can be arranged in the same layer, and the second repair line 551 can be arranged in the same layer. 552 and the data line 520 ar...

no. 3 example

[0080] This embodiment introduces in detail the specific repairing method of the array substrate with repaired lines of the present invention.

[0081] Figure 7 It is a flow chart of the method for repairing defects of the array substrate in the third embodiment of the present invention. FIG. 8 is a schematic diagram of the array substrate of the liquid crystal display device repaired by the repair method in the third embodiment of the present invention. The following combines Figure 7 and FIG. 8 specifically introduce the repairing method of this embodiment.

[0082] Step 701: Detect and determine the defects of the data lines on the array substrate. As shown in FIG. 8 , open circuit defects 841 and 842 appear on the data lines D(n+3) and D(n+5), respectively. If the array substrate does not have the repaired circuit of the present invention, the two columns of pixel units cannot display normally, and the array substrate can only be scrapped. However, the array substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com