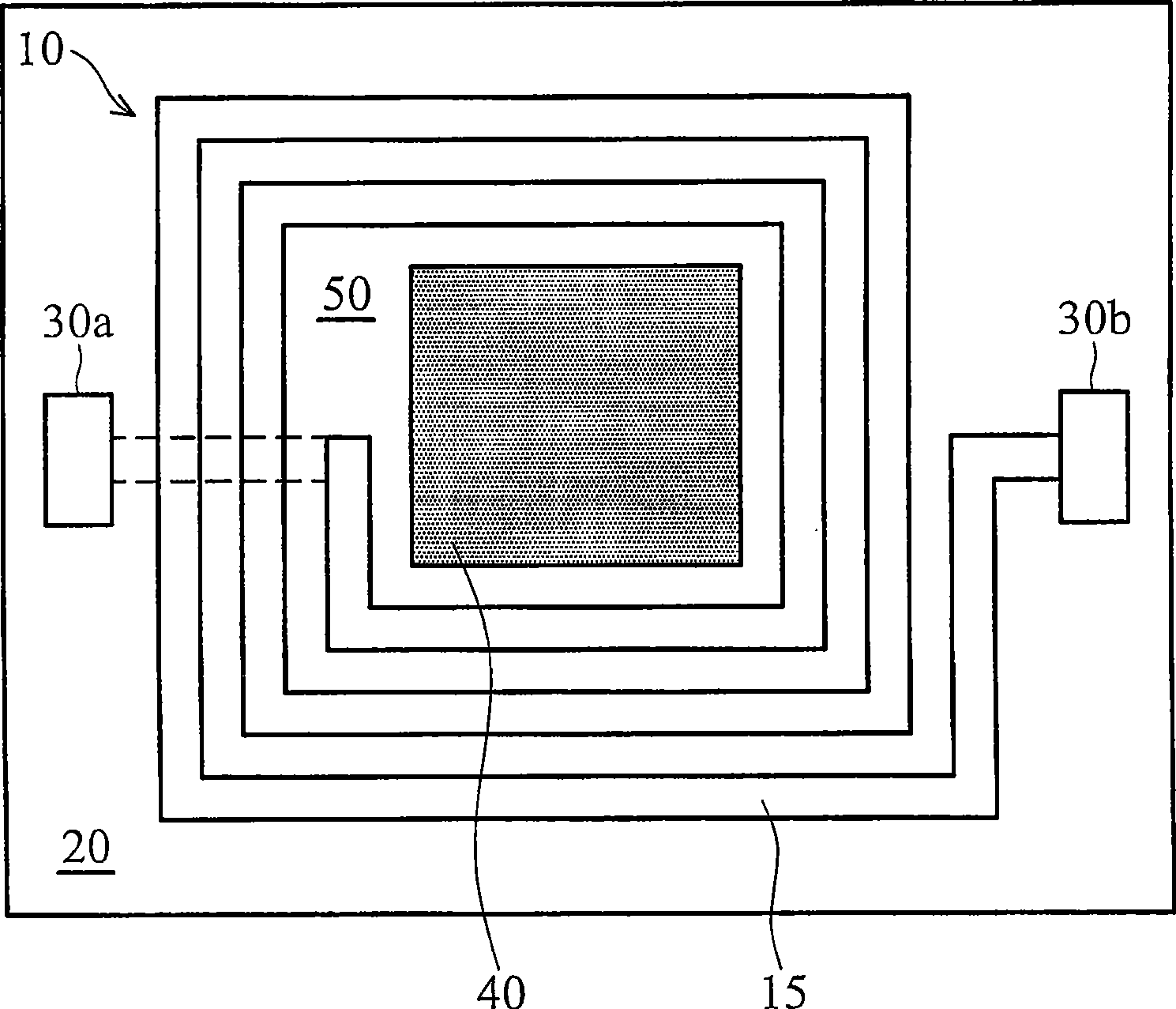

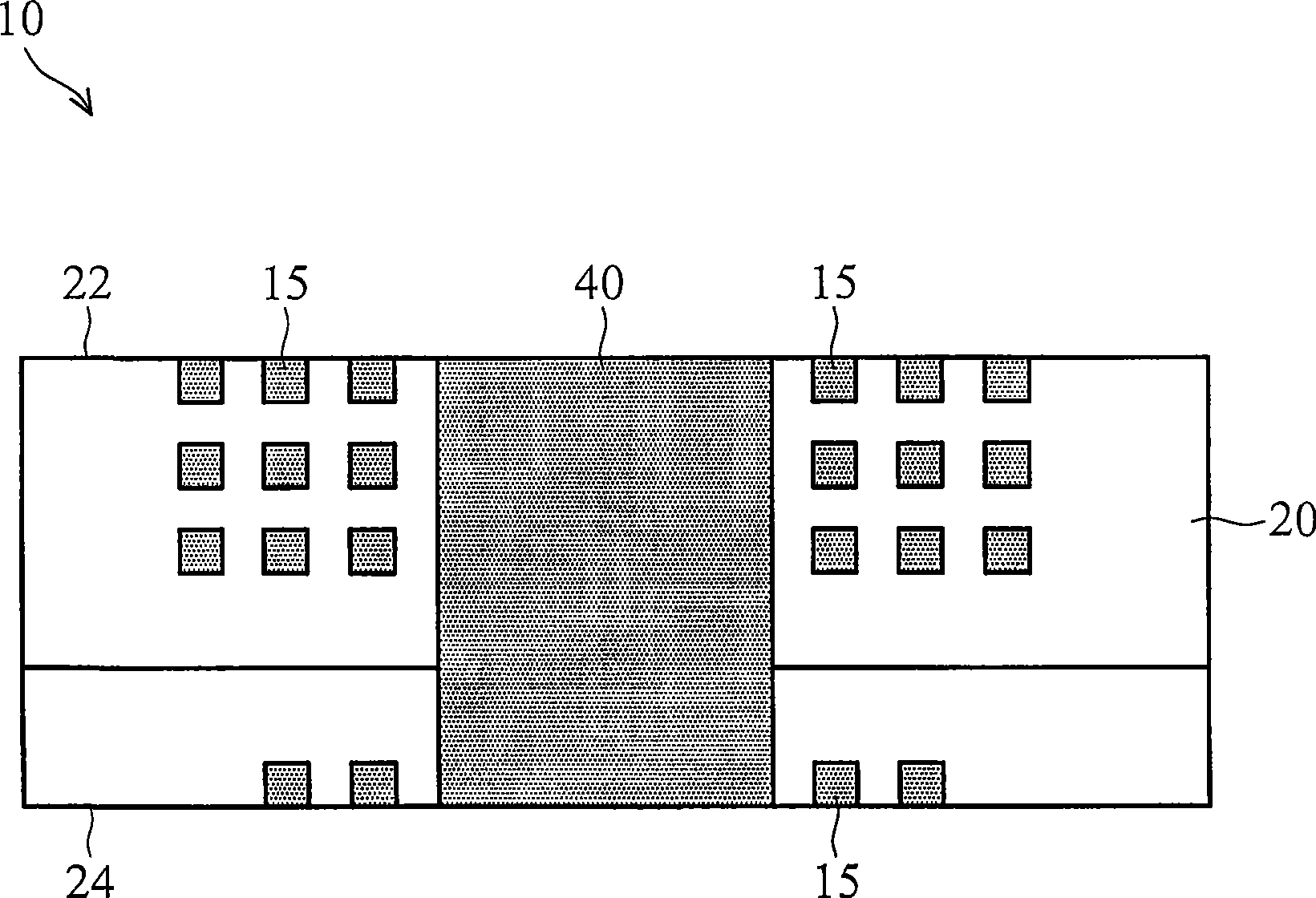

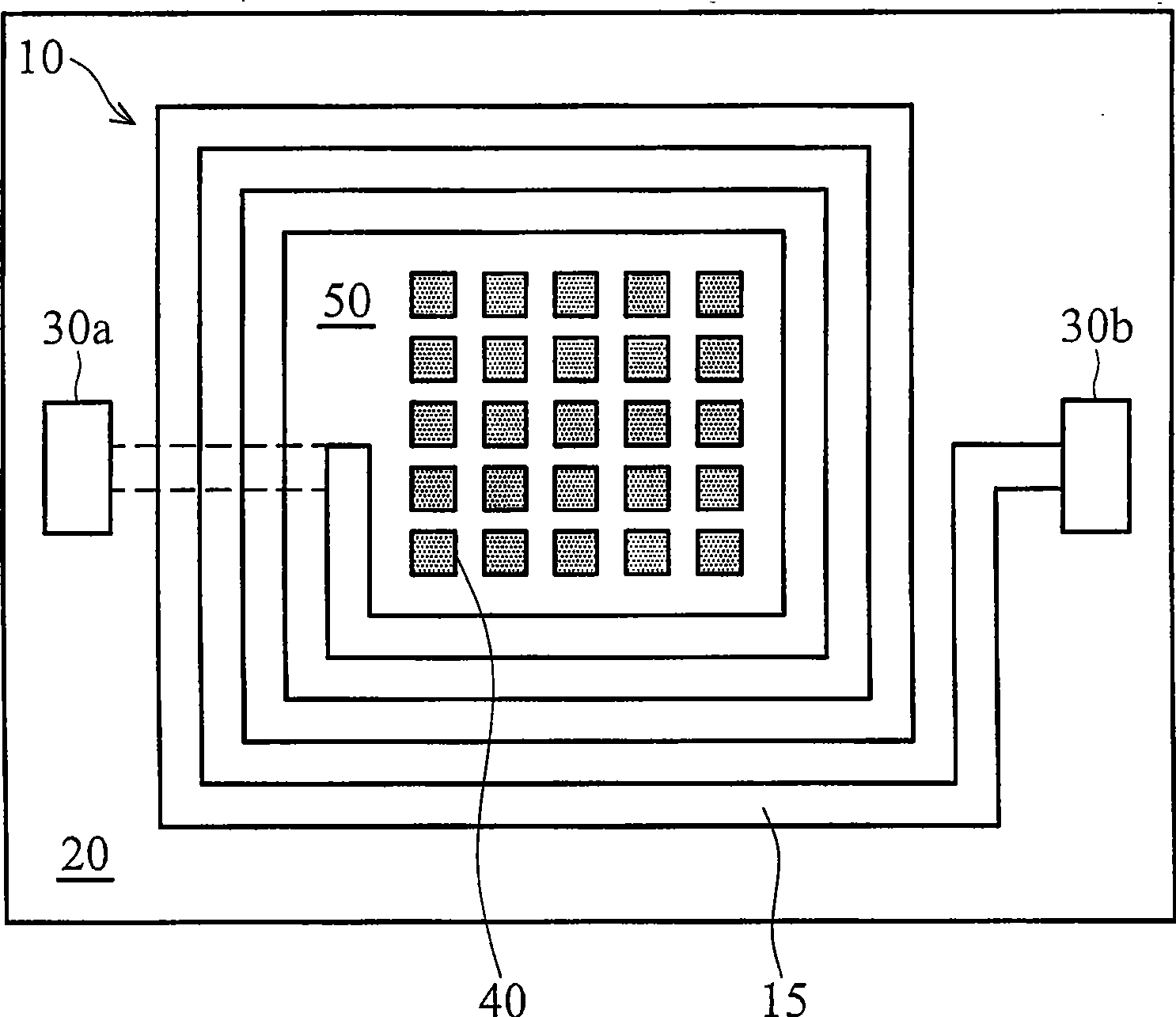

Spiral inductor structure, fabricating method and packing structure thereof

A technology of spiral inductors and packaging structures, applied in the manufacture of inductors/transformers/magnets, inductors, printed inductors, etc., can solve problems such as low quality factor and difficult preparation, and achieve the effect of improving the quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention has been disclosed in the following specification with several preferred embodiments, but it is not intended to limit the present invention, and any person skilled in the art should be able to make arbitrary changes without departing from the spirit and scope of the present invention. Move and modify. In some instances, well-known structures and processes have not been described in detail in order to avoid obscuring the present invention.

[0039] In the reference examples in the specification, "an embodiment" or "an embodiment" means a specific pattern, structure or feature in at least one embodiment of the present invention. Thus, terms that appear in the specification, such as "one embodiment" or "one embodiment," do not necessarily all refer to the same embodiment. Furthermore, special patterns, structures or features may be combined in any suitable manner in one or more embodiments. The following figures are not drawn to scale and are for il...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com