Method and device for setting and activating a hydrodynamic retarder of a motor vehicle

A technology of hydraulic reducer and reducer, which is applied in the direction of hydraulic brake, brake type, mechanical equipment, etc., can solve the problems of high cost and structural expenditure, and achieve the effect of improving accuracy and adjusting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

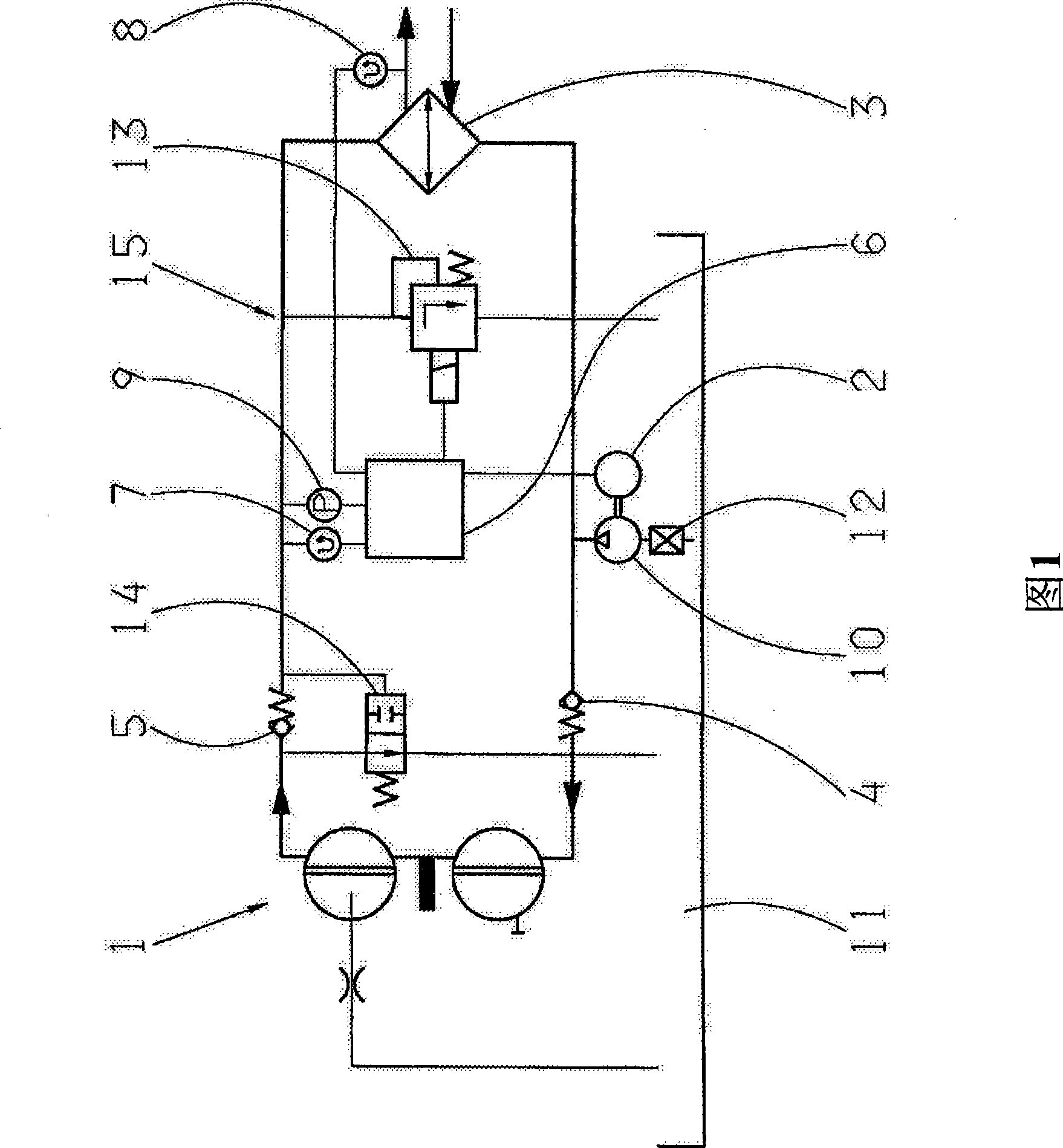

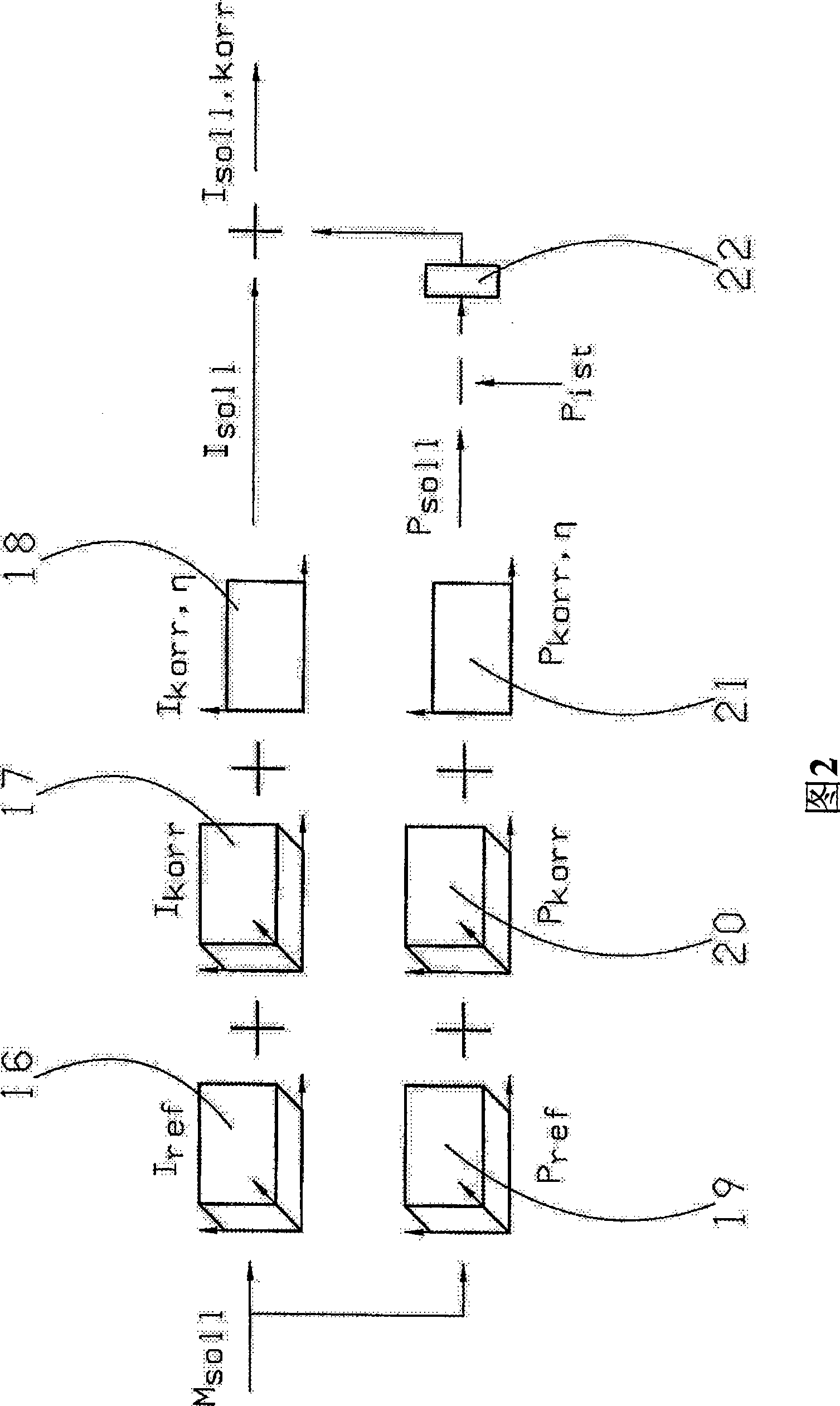

[0049] FIG. 1 shows a vehicle retarder circuit 15 formed as a working circuit of the hydrodynamic retarder 1 . The structure and operating principle of such gear units are well known, so that only the components relevant to the invention will be discussed in detail here.

[0050] The working circuit 15 has a pump 10 and an upstream filter 12 for oil supply, the pump 10 can be driven and adjusted by the electric motor 2 . The pump 10 may be supplied with oil from an oil pan 11 . Furthermore, a heat exchanger 3 is provided for dissipating the kinetic energy of the flow converted into heat in the gear unit 1 . For filling and emptying the gear unit 1, two non-return valves 4, 5 are arranged on the inlet or outlet side, wherein an emptying valve 14 is additionally arranged on the gear unit outlet, via which the The gear unit 1 can be completely emptied.

[0051] The working circuit 15 can be adjusted by the control and regulation unit 6 . The control and regulation unit 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com