Tandem-mill strip-steel vibration marks detection method

A detection method and vibration pattern technology, applied in metal rolling, length measuring device, metal rolling, etc., can solve problems such as unfavorable production site promotion, vibration pattern early warning system has not been seen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

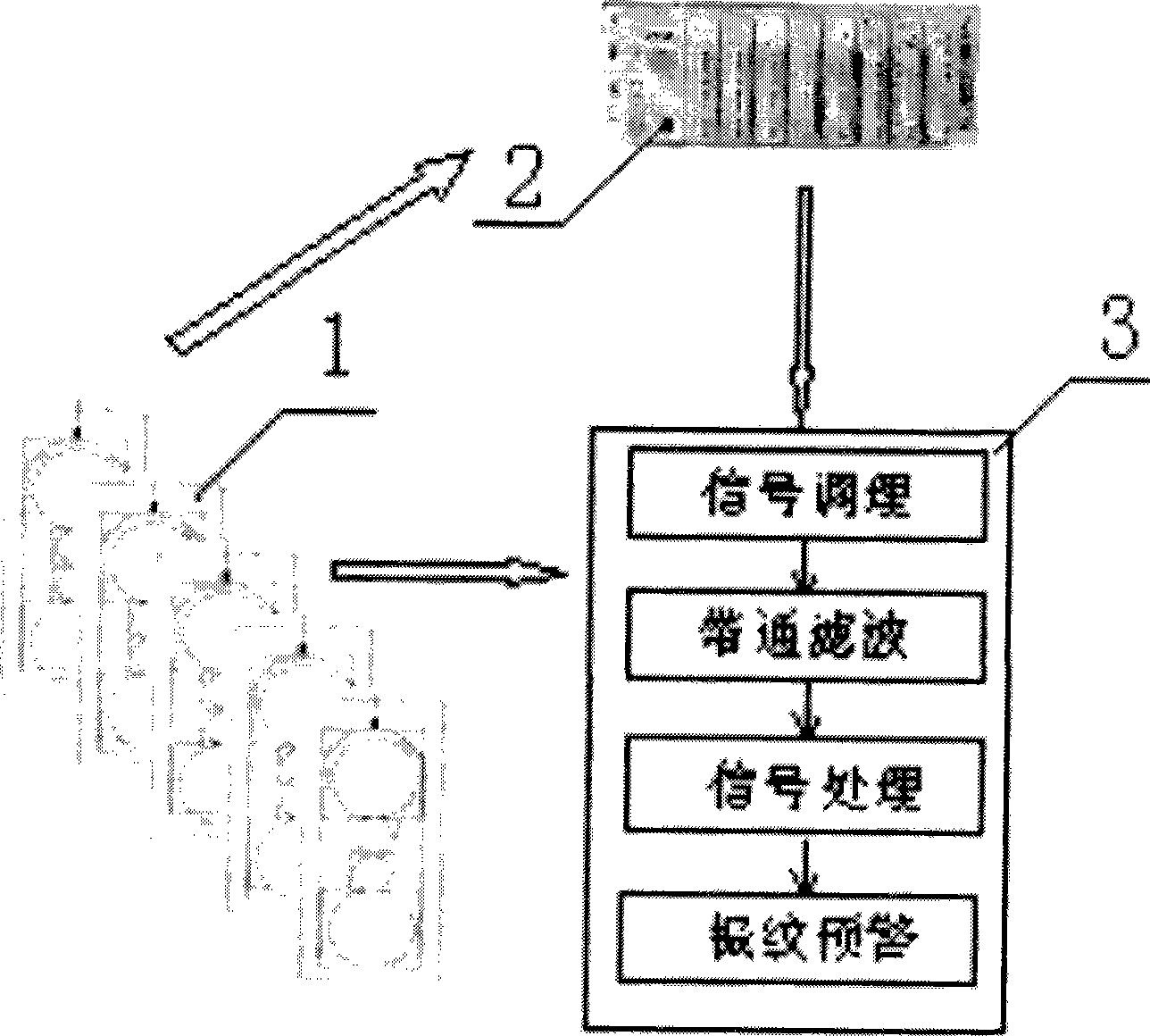

[0034] As shown in the figure, the strip steel vibration mark detection device 3 carries out synchronous collection of the rolling mill vibration signal from the rolling mill 1 and the process signals such as the speed and steel coil from the rolling mill control system 2, and detects the strip steel vibration mark according to the following method And signal processing, and realize vibration pattern early warning.

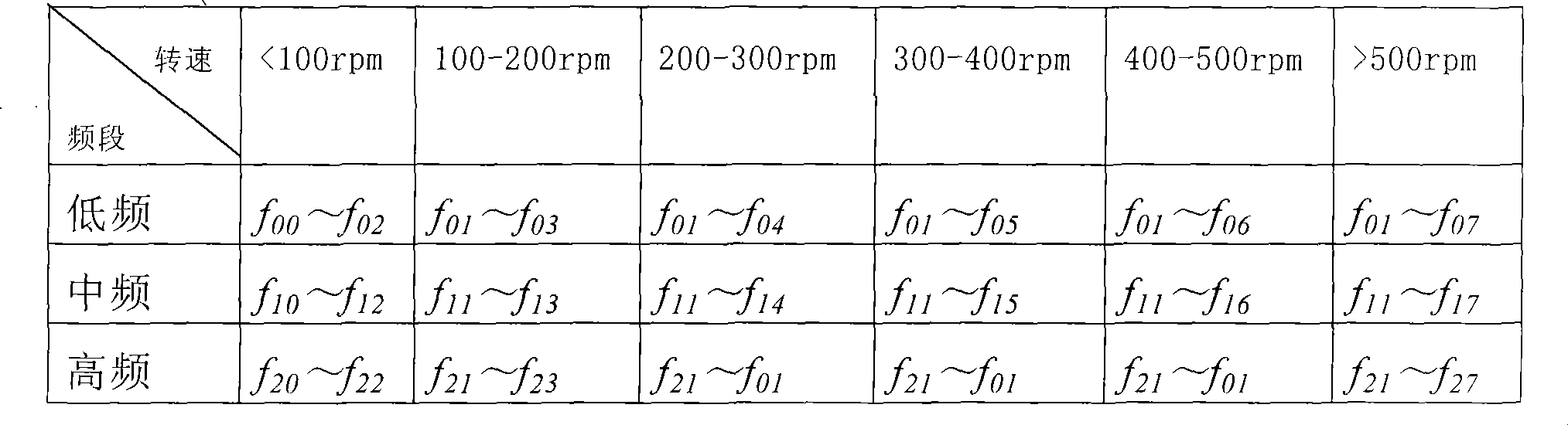

[0035] Step 1: For each set of original signal and rolling speed, divide the original signal into segments according to the speed range, and the segmentation is as follows:

[0036] Rotating speed

frequency band <100rpm

100-200rpm

200-300rpm

300-400rpm

400-500rpm

>500rpm

low frequency f 00 ~ f 02 f 01 ~ f 03 f 01 ~ f 04 f 01 ~ f 05 f 01 ~ f 06 f 01 ~ f 07 IF f 10 ~ f 12 f 11 ~ f 13 f 11 ~ f 14 f 11 ~ f 15 f 11 ~ f 16 f 11 ~ f 17 high frequency f 20 ~ f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com