High-stability heavy-load clamp

A high-stability, clamp technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of high rotation speed of clamps, reduced preload clamping force, different deflection stiffness, etc., to improve the bearing capacity and bearing space, ensure clamping stability, and improve the effect of clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

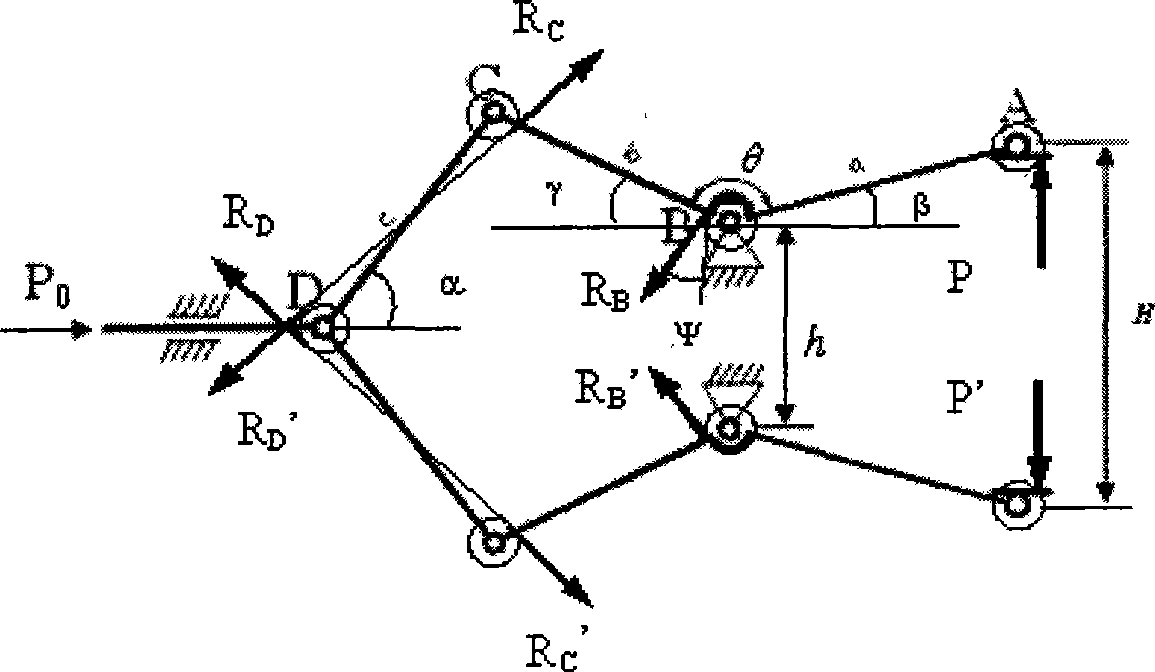

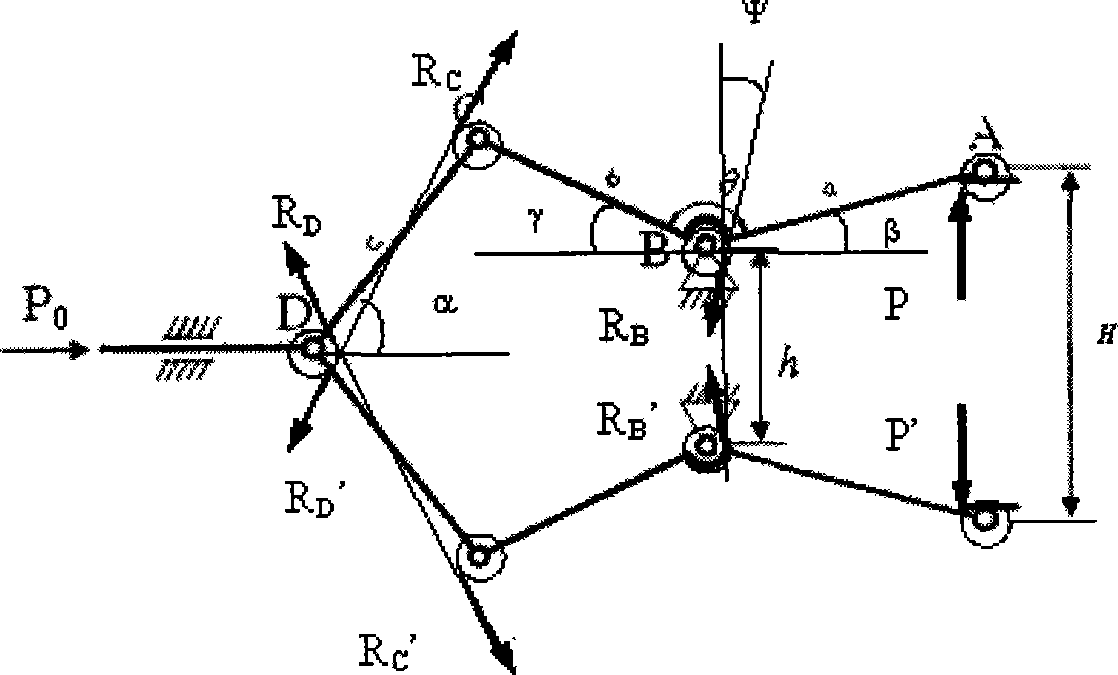

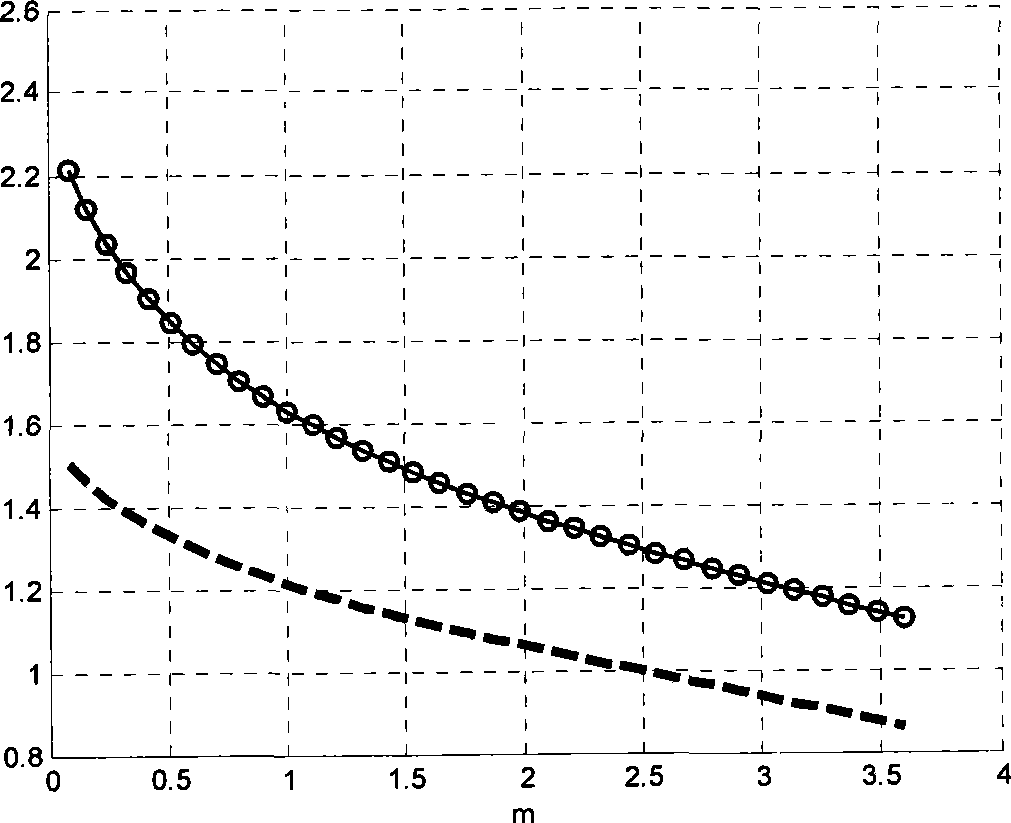

[0037] The present invention finds out a method for improving the load-bearing capacity, load-bearing space and clamping stability of the clamp by utilizing the reaction force response blind area through in-depth research on the clamping mechanism and force flow transmission law of the clamp; and through the clamp mechanism The size and structure are optimized to provide a high-stability heavy-duty clamp. The specific implementation is as follows:

[0038] The clamp adopts an auxiliary mechanism—a parallelogram mechanism composed of the clamp arm 3, the clamp head 4, the frame 5 and the pull rod 6, see Figure 7, when the opening of the jaws changes, the pincer head 4 always maintains a horizontal position to limit the deflection angle of the forging when it is clamped vertically, so that the actual average working tension P 工 Greater than or greater than the pre-tightening clamping force P 预 Even when the critical working tension is exceeded, the clamping stability can stil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com