Assembly apparatus of coating head and moutning method

A coating device and assembly device technology, which is applied to the surface coating liquid device, assembly machine, spraying device, etc., can solve the problem of no specific disclosure of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

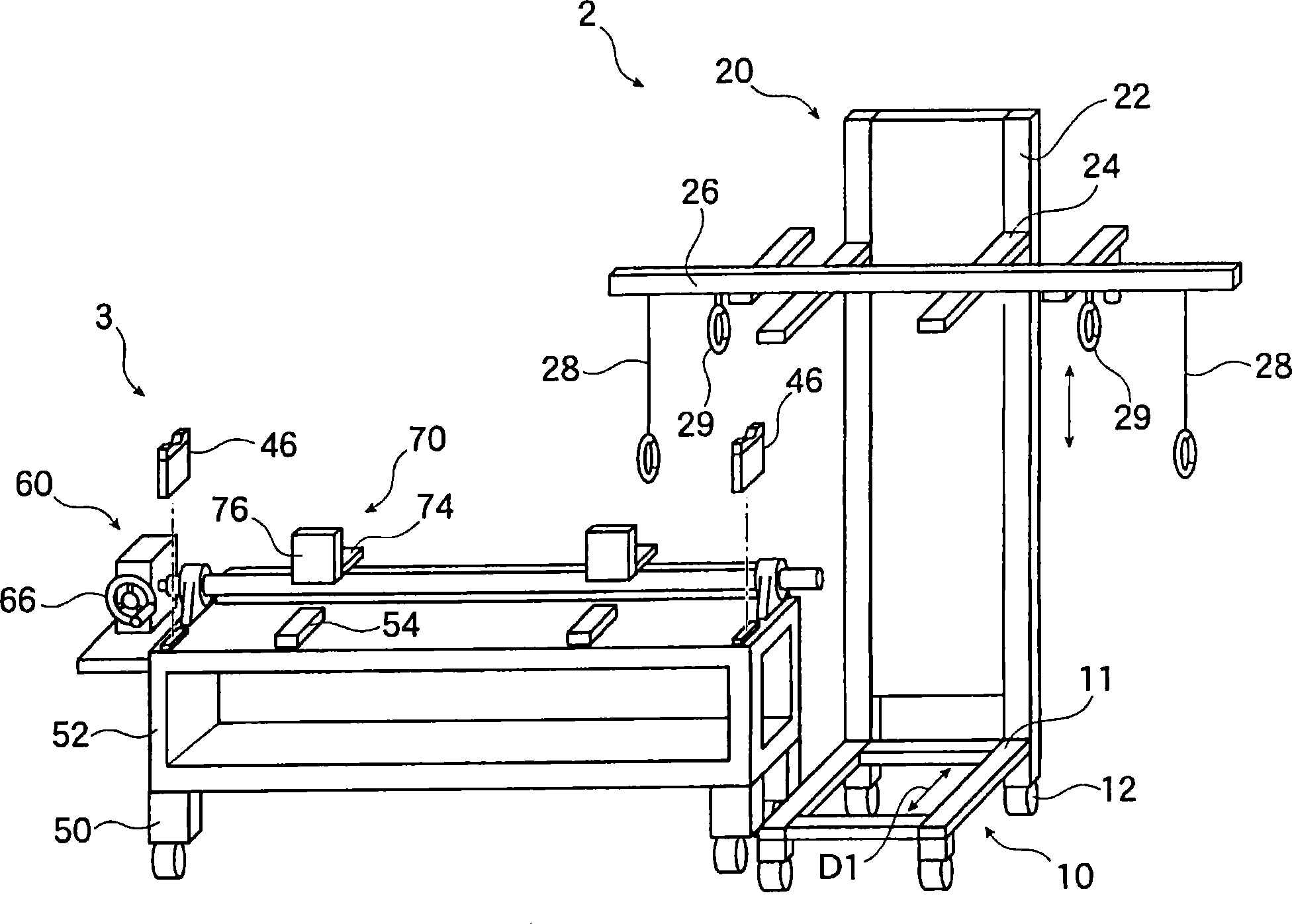

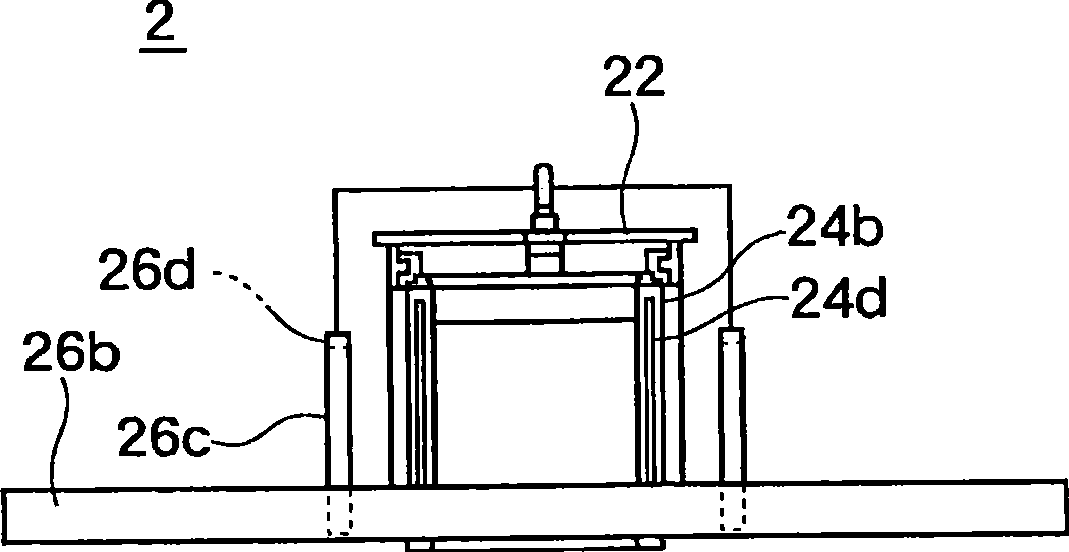

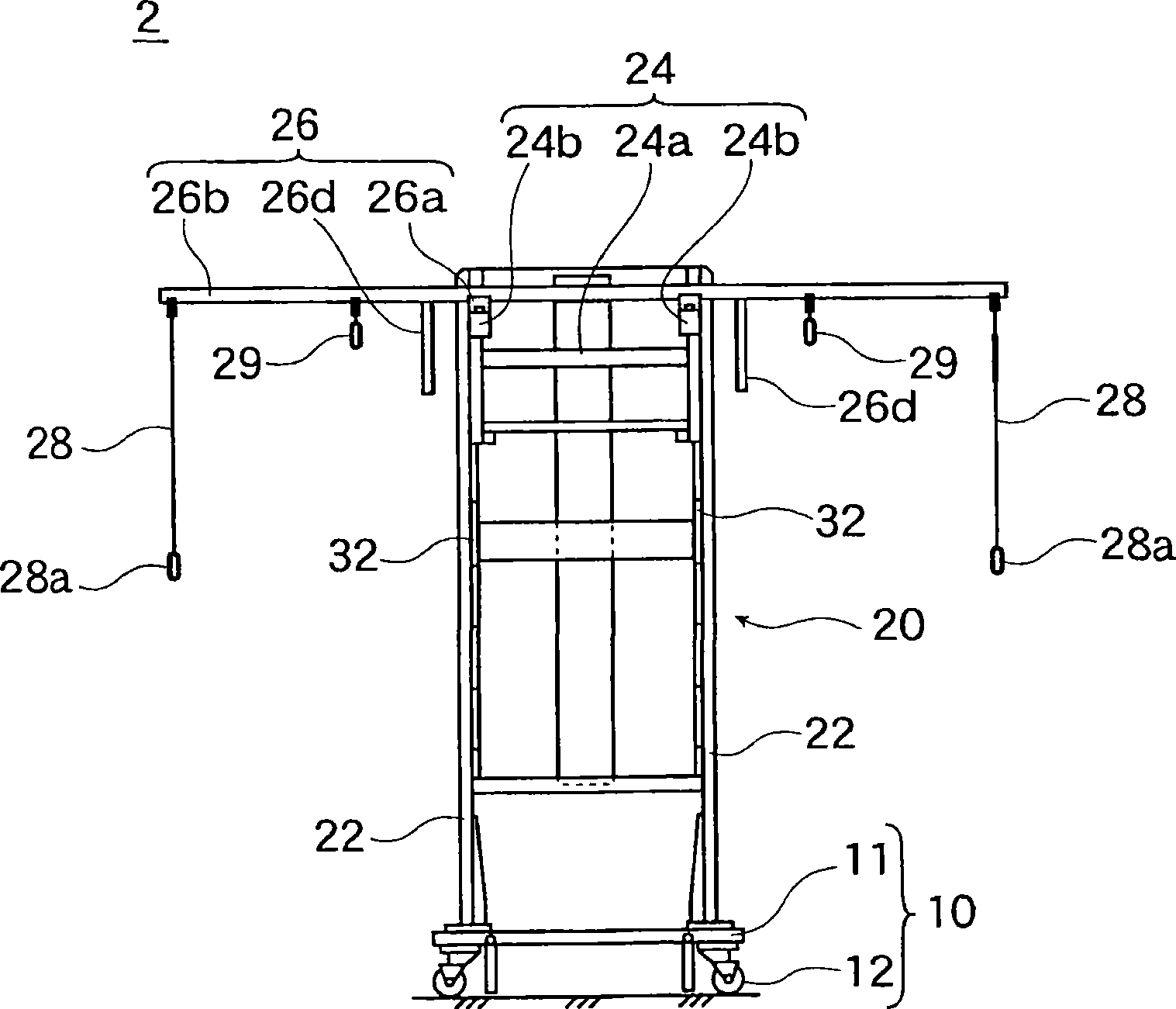

[0084] Preferred embodiments of the assembly device and installation method of the applicator head according to the present invention will be described in detail below with reference to the drawings. Prior to this description, first, a brief description will be given of the coating head to be assembled and the liquid coating device to which the coating head is mounted.

[0085] The liquid application device is used to apply a liquid such as a resist or a chrome coating solution to the surface of an object to be applied, such as a semiconductor substrate or a liquid crystal substrate, with a uniform thickness.

[0086] As shown in FIG. 28 , a liquid application device 101 has a base 102 and a table 103 provided at the center of the base 102 , and a substrate 104 to be coated is placed on the table 103 . Two side edges of the base 102 are respectively formed with vertical sidewalls 102a, 102b, and guide rails 105a, 105b are laid on the sidewalls 102a, 102b. Furthermore, on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com