DME fuel filling system

A fuel and fuel tank technology, applied in the field of DME fuel filling system, can solve the problems of shortening and not fully achieving DME fuel filling time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

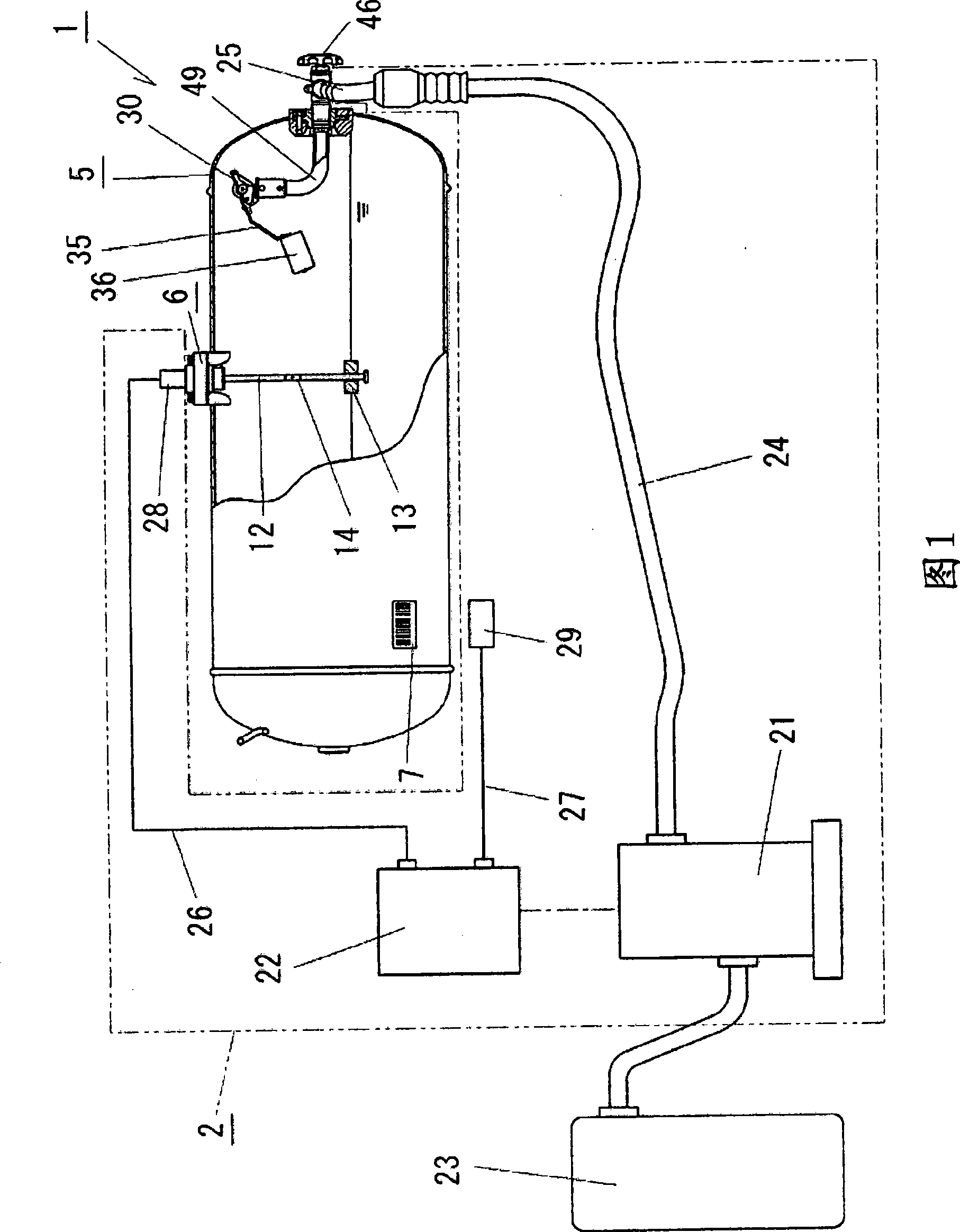

[0070] In Embodiments 1 and 2, as shown in FIGS. 1 and 6, DME fuel filling systems 1, 51 are equipped with fuel filling devices 2, 52 for filling DME fuel into fuel tanks 5, 55 arranged horizontally on automobiles. . At this time, the fuel charging control device 2, 52 is usually arranged at a DME fuel supply station. In Embodiment 3, like Embodiments 1 and 2, it is a DME fuel filling system provided with a horizontal fuel tank and a fuel filling control device.

Embodiment 1

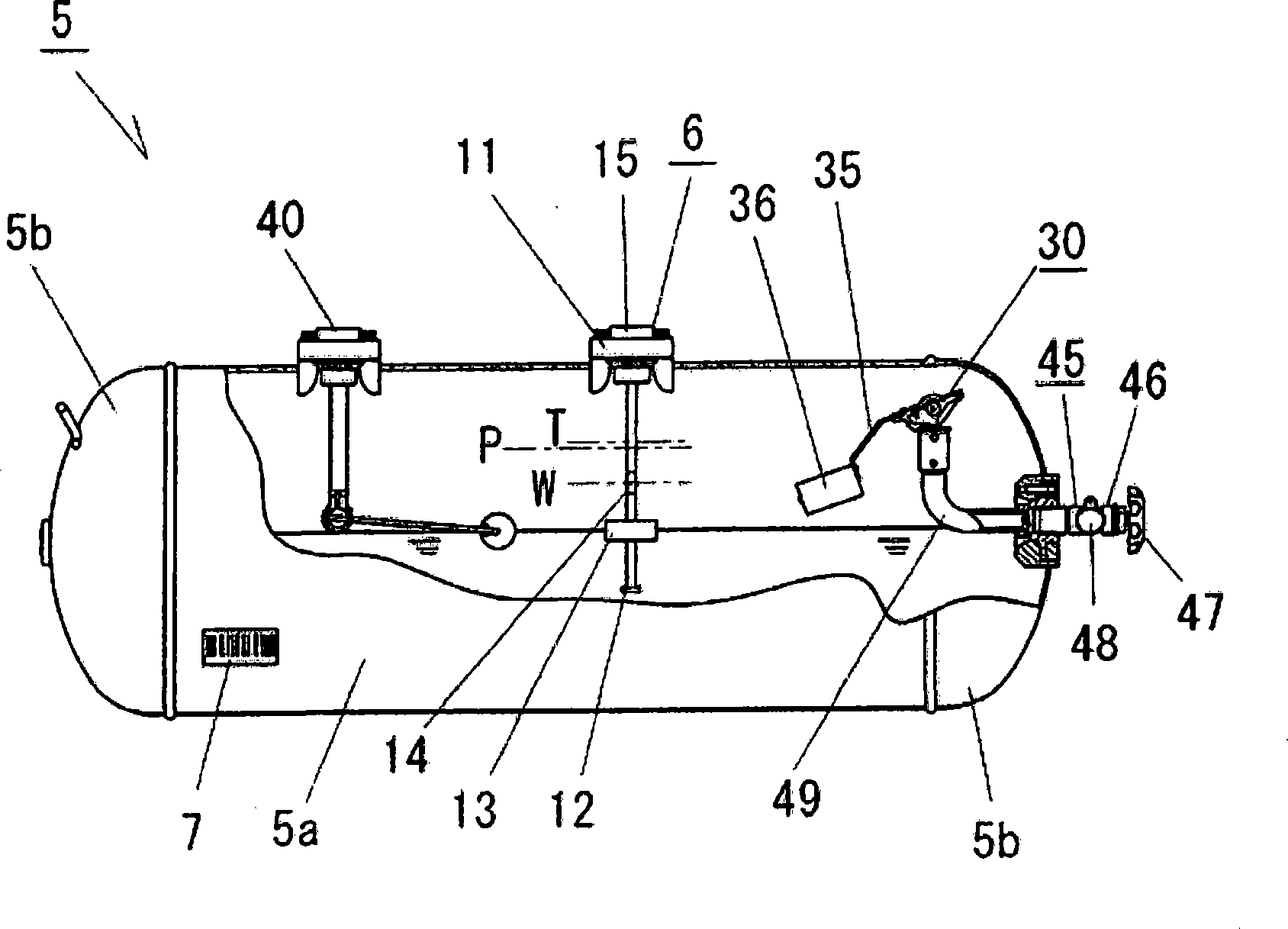

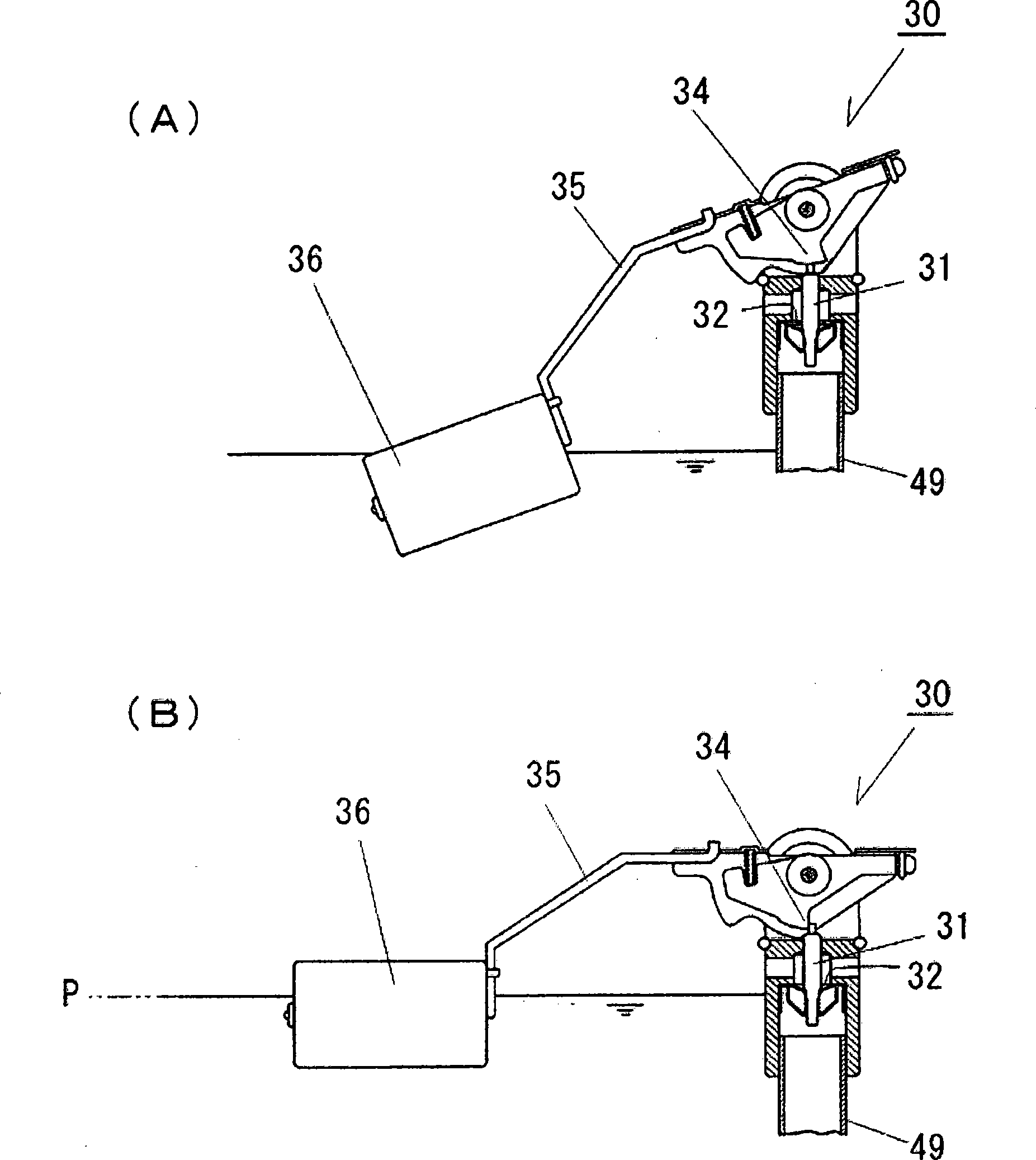

[0072] For example, as a fuel tank 5 arranged horizontally on a truck, such as figure 2 As shown, it consists of a cylindrical tube part 5a and hemispherical tube cover parts 5b, 5b joined to openings on both sides of the tube part 5a. This fuel tank 5 is fixed on the vehicle by a fixing member (not shown), and a valve device equipped with a filling valve 46 and a filling valve opening and closing handle 47 for opening and closing the filling valve 46 is arranged on one of the cylinder cover parts 5b. 45. And, on this filling valve 46, be provided with the fast coupling device 48 (quick-coupling) of detachable later-mentioned filling nozzle 25, when filling DME fuel, install filling nozzle 25 on the quick coupling device 48 and Fill up with fuel.

[0073] Furthermore, in the fuel tank 5, a gas filling pipe 49 communicating with the above-mentioned filling valve 46 is arranged. Furthermore, the gas filling pipe 49 has its front end provided at the upper portion inside the fu...

Embodiment 2

[0110]In the structure of Embodiment 2, as shown in FIG. 6 , the structure is as follows: the fuel tank 55 is not provided with the overfill prevention device 30 of Embodiment 1, the liquid level detection device 56 is equipped with a deceleration position switch 14, and if it reaches the maximum filling amount, it can be displayed. The maximum liquid height P of the maximum liquid level is then according to the maximum position switch 64 of the ON action of the float 13 . That is, when the DME fuel is filled, the liquid level rises, and if it reaches the maximum liquid level P, the buoy 13 makes the maximum position switch 64 ON. Acquired by the filling control device 22.

[0111] Furthermore, the filling control device 22 has filling stop control processing contents such as obtaining the liquid level information indicating the ON operation of the maximum position switch 64 from the above-mentioned liquid level detection device 56 and driving and stopping the fuel filling mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com