Shunt type automatic vertical well drilling tool suitable for gas drilling

A vertical drilling and gas drilling technology, applied in liquid/gas jet drilling, directional drilling, etc., can solve problems such as unbalanced drilling, bending deformation, wellbore deflection, etc., and achieve wide application range, stable performance, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

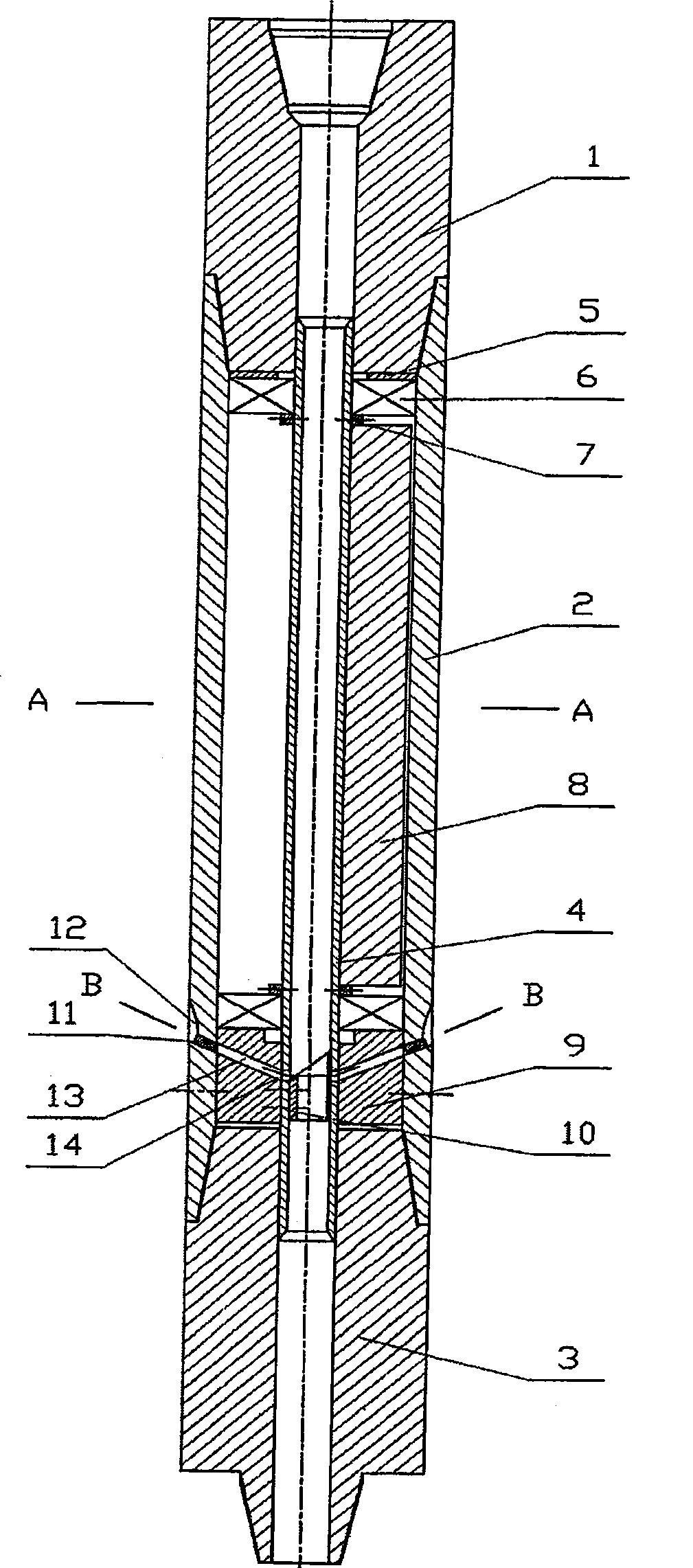

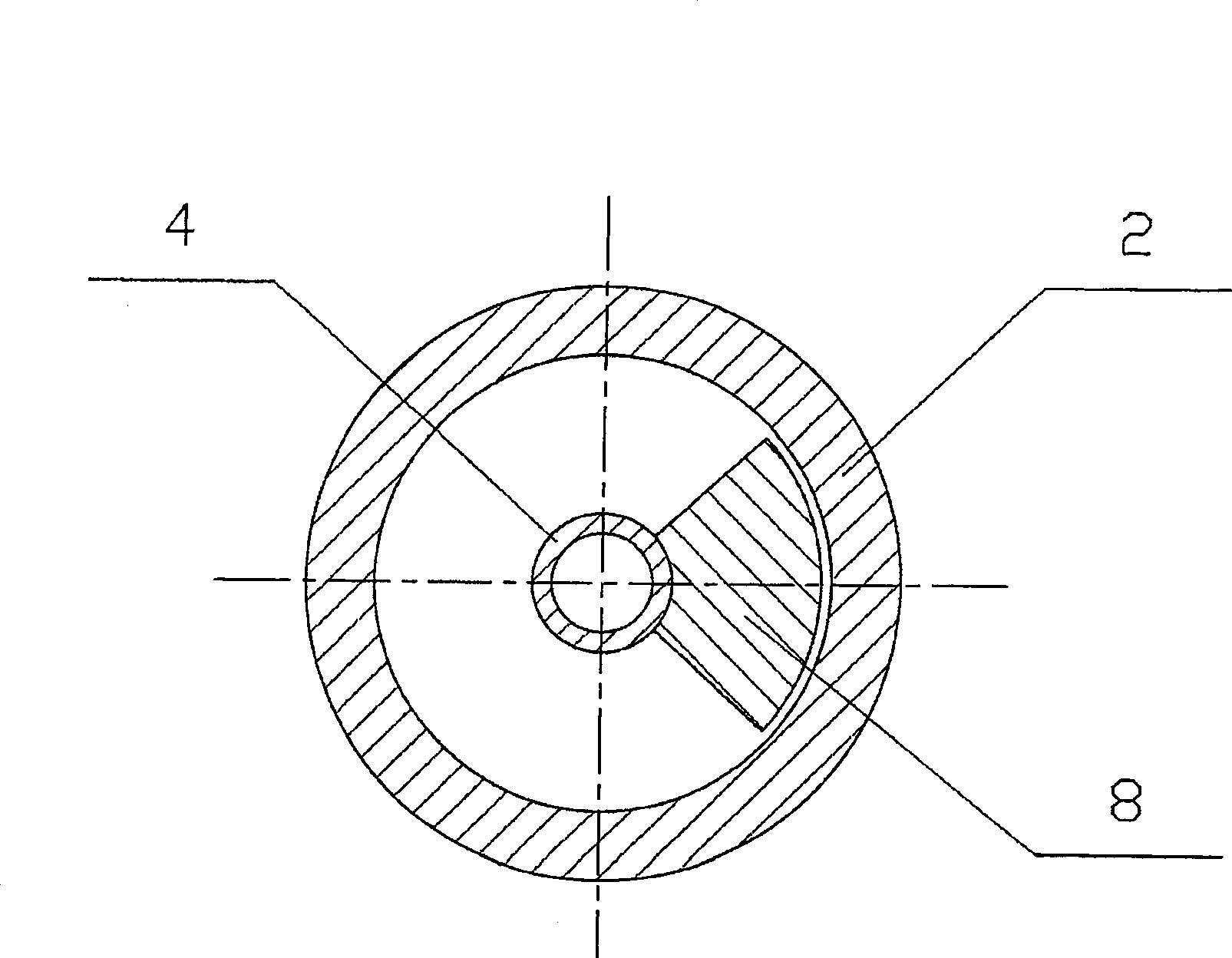

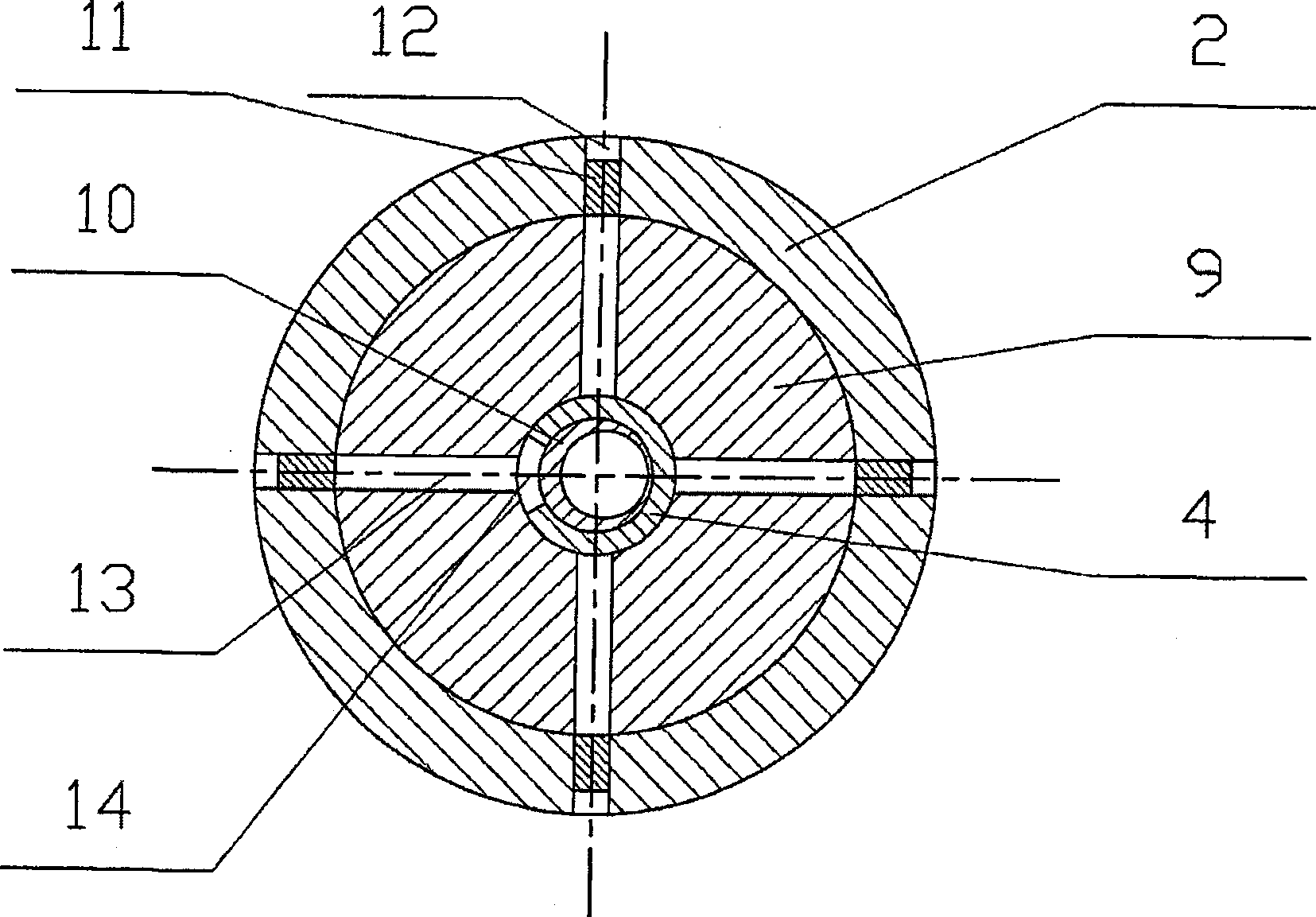

[0027] Combine now figure 1 , figure 2 and image 3 The present invention is further described. This split-flow automatic vertical drilling tool suitable for gas drilling is based on the principle of gas dynamics and fluid-solid coupling analysis method, and uses the split-flow gas method to adjust the reaction force of the split-flow jet to adjust the lateral force of the drill bit to realize automatic induction of well deviation and deviation correction. To achieve the purpose of vertical drilling construction.

[0028] When adopting the present invention to carry out the construction of vertical well drilling, calculate the diameter of the spray body hole required, and select the valve 11. according to figure 1 Assemble, the bearings 6 are installed on both sides of the baffle 7 respectively, and are interference fit with the core tube 4, the counterweight 8 is fixed in the middle of the two baffles 7 of the core tube 4 by welding, and the counterweight 8 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com