Non-contact electronic throttle angle sensor for automobile

An angle sensor and automotive electronics technology, applied in the direction of instruments, electrical control, and electrical devices, can solve the problems of easy wear, interference with ECU working status, poor reliability, etc., and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

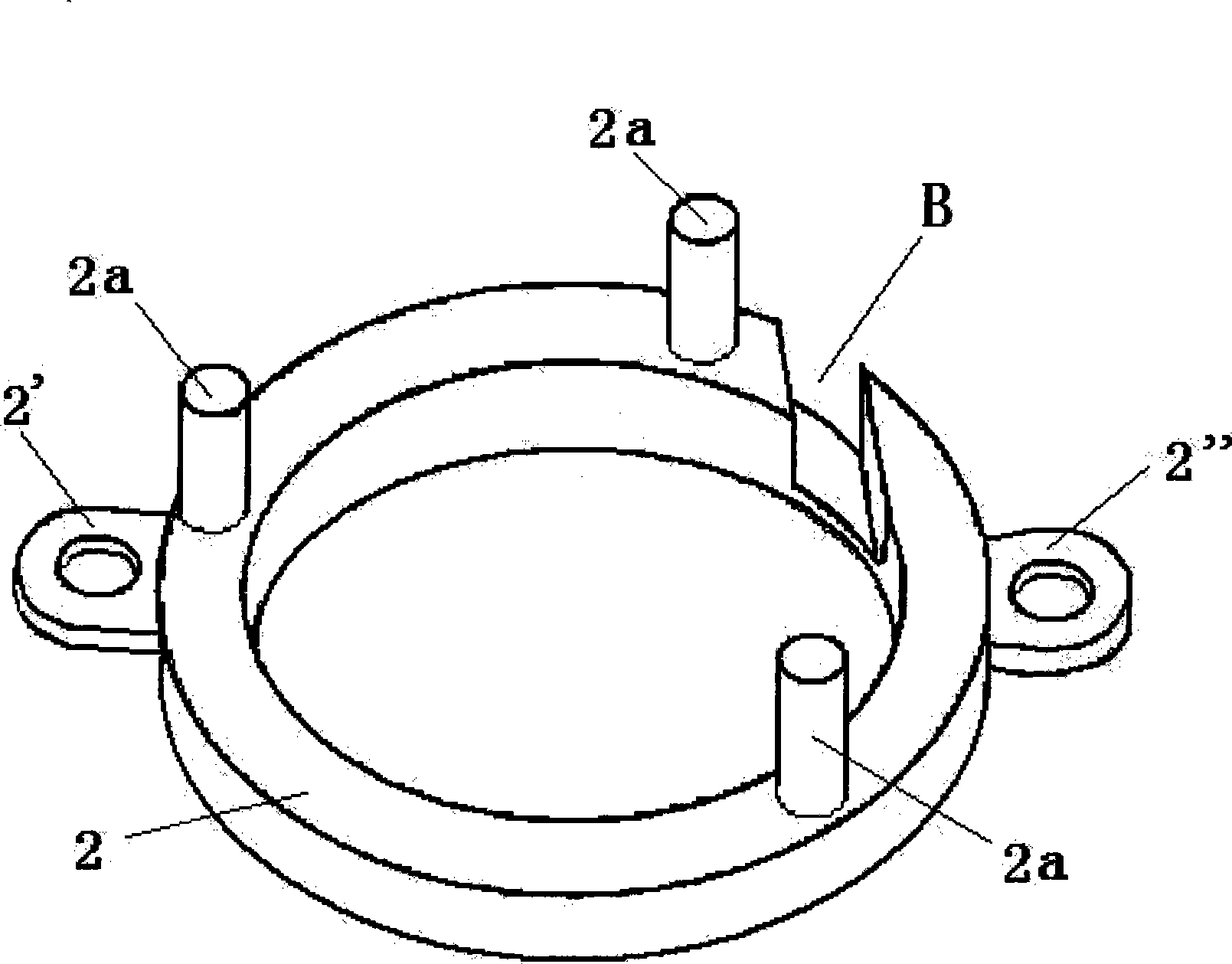

[0019] Embodiment 1, combining image 3 , in the figure: 2 is the positioning pressure ring, 2' and 2" are the earrings, the earrings 2' and 2" are integrated with the positioning pressure ring 2, the earrings 2' and 2" are on the side of the positioning pressure ring 2, the earrings 2' and 2" is used to fix the positioning pressure ring 2. 2a is a foot. The foot 2a is integrated with the positioning pressure ring 2. The foot 2a is on the bottom surface of the positioning pressure ring 2. The foot 2a is used for precise positioning of the positioning pressure ring 2. The foot 2a is cylindrical Either a square column or a triangular column, the bottom of the foot 2a is a plane or spherical or conical surface, B is a groove, the groove B is on the bottom surface of the positioning pressure ring 2, and the groove B is used to limit one end of the spring 7 7a.

[0020] combine Figure 4 , in the figure: 7 is the spring, 7a and 7b are the two ends of the spring 7 respectively.

...

Embodiment 2

[0022] Example 2, combined with Figure 6 , in the figure: 2 is the positioning pressure ring, 2a is the foot, the difference between embodiment 1 and embodiment 2 is that the foot 2a on the positioning pressure ring 2 in embodiment 1 is cylindrical or square column or triangular column Shaped column, and the foot 2a on the positioning pressure ring 2 among the embodiment 2 is the wave chain type flat-bottomed shape foot.

Embodiment 3

[0023] Example 3, combined with Figure 7 , in the figure: 2 is the positioning pressure ring, 2a is the foot, the difference between embodiment 1 and embodiment 2 and embodiment 3 is: the foot 2a on the positioning pressure ring 2 in embodiment 1 is cylindrical or square column Shaped or triangular column, the pin 2a on the positioning pressure ring 2 in embodiment 2 is a wave chain type flat-bottomed foot, and the pin 2a on the positioning pressure ring 2 in embodiment 3 is a wave chain type arc bottom shape foot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com