Basic electric parameter static measurement method for three phase permanent magnet synchronous machine

A permanent magnet synchronous motor, electrical parameter technology, applied in the direction of motor generator testing, measuring devices, measuring electrical variables, etc., can solve problems such as noise and inconvenience, and achieve the effect of avoiding noise problems, simplifying costs and procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

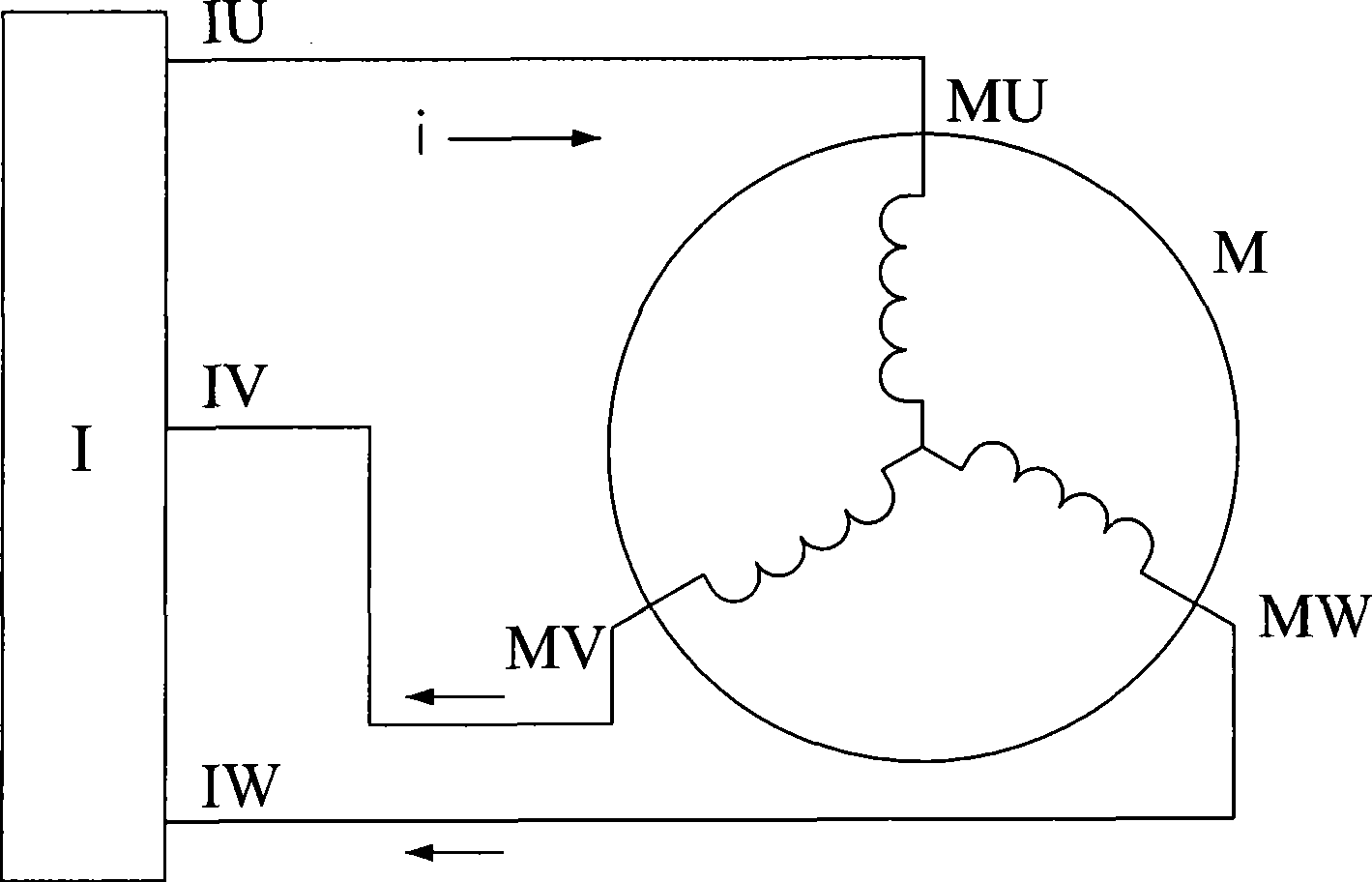

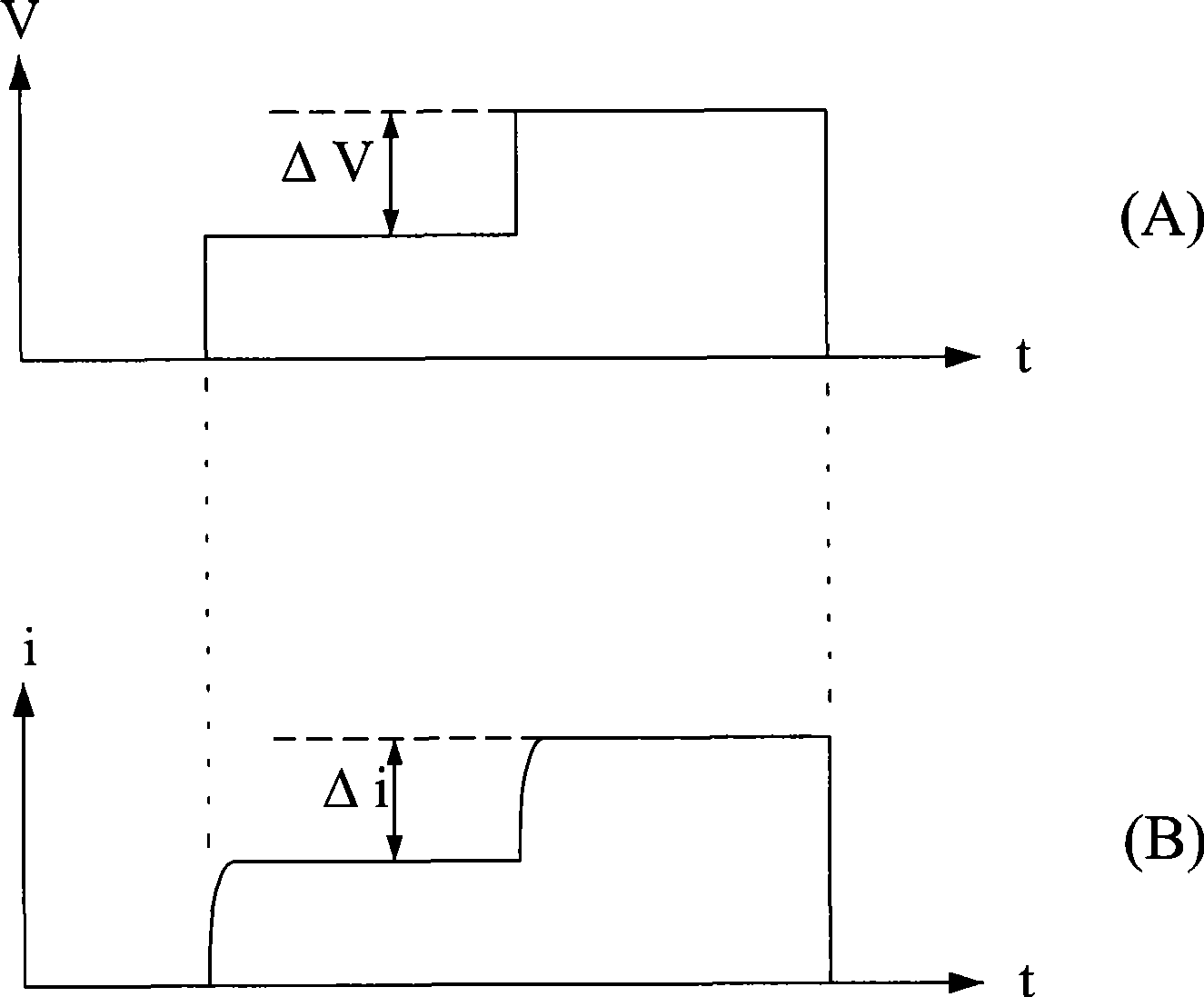

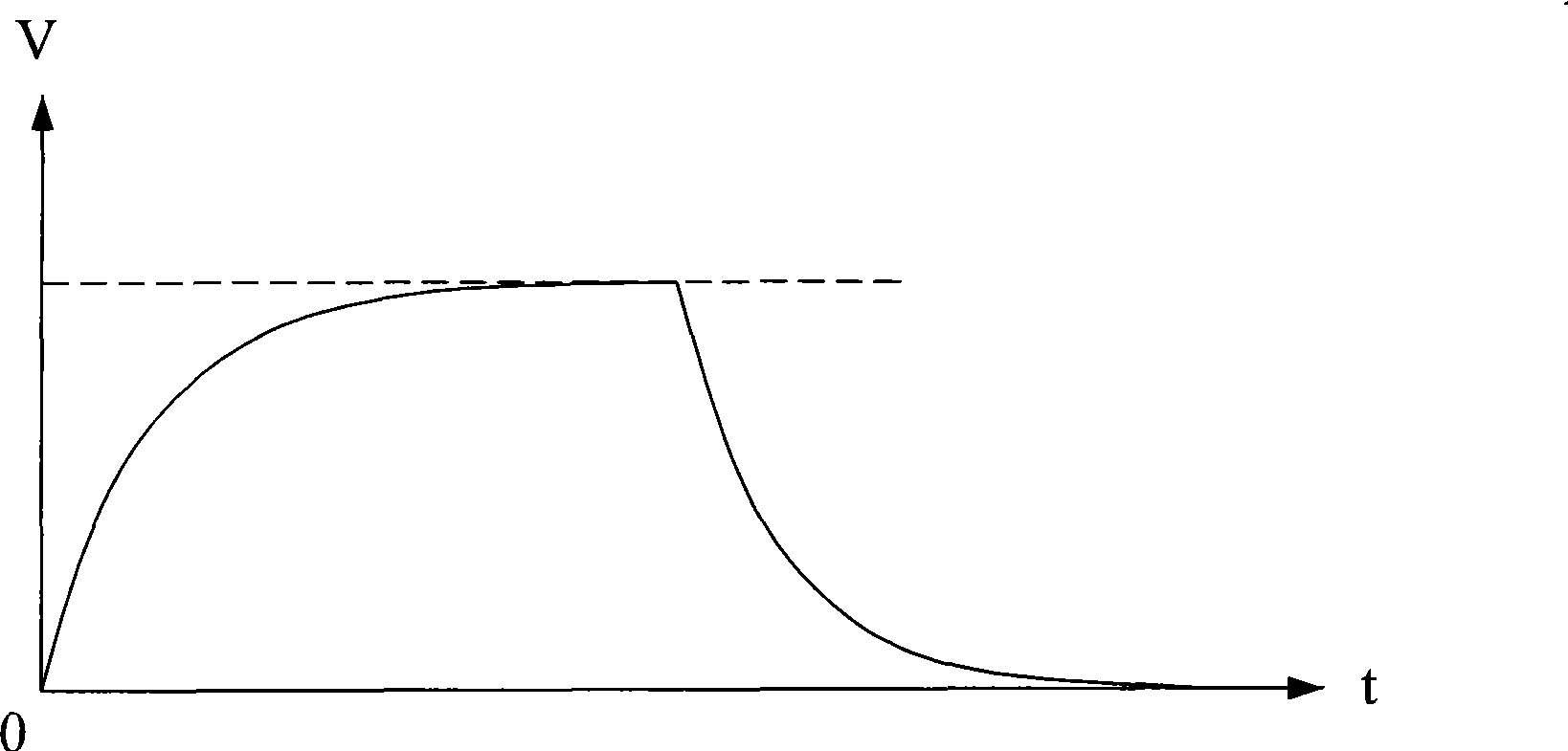

[0033] The basic electrical parameters of a rotating electrical machine are mainly motor resistance and motor inductance. The measurement of the present invention is divided into two stages, the first stage is to measure the motor resistance, and the second stage is to measure the motor inductance. see figure 1 , which is a system architecture diagram of the present invention when measuring motor resistance, for connecting the three power supply input terminals MU, MV and MW of the three-phase permanent magnet synchronous motor M to be tested to the output terminals IU, IV and IW of the frequency converter I respectively , to control the output voltage of the frequency converter I so that it can achieve the DC voltage input function, and lock the rotating shaft (not shown) of the motor M to be tested with a mechanical brake (not shown) so that it cannot run, please refer to Figure 5 , the left half of which shows the measurement process of the motor resistance. Firstly, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com