Case for magnetron

A magnetron and tube-shell technology, applied in the field of magnetrons, can solve the problems of reducing the heat dissipation performance of the magnetron, large energy heat loss, reducing the output power of the magnetron, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

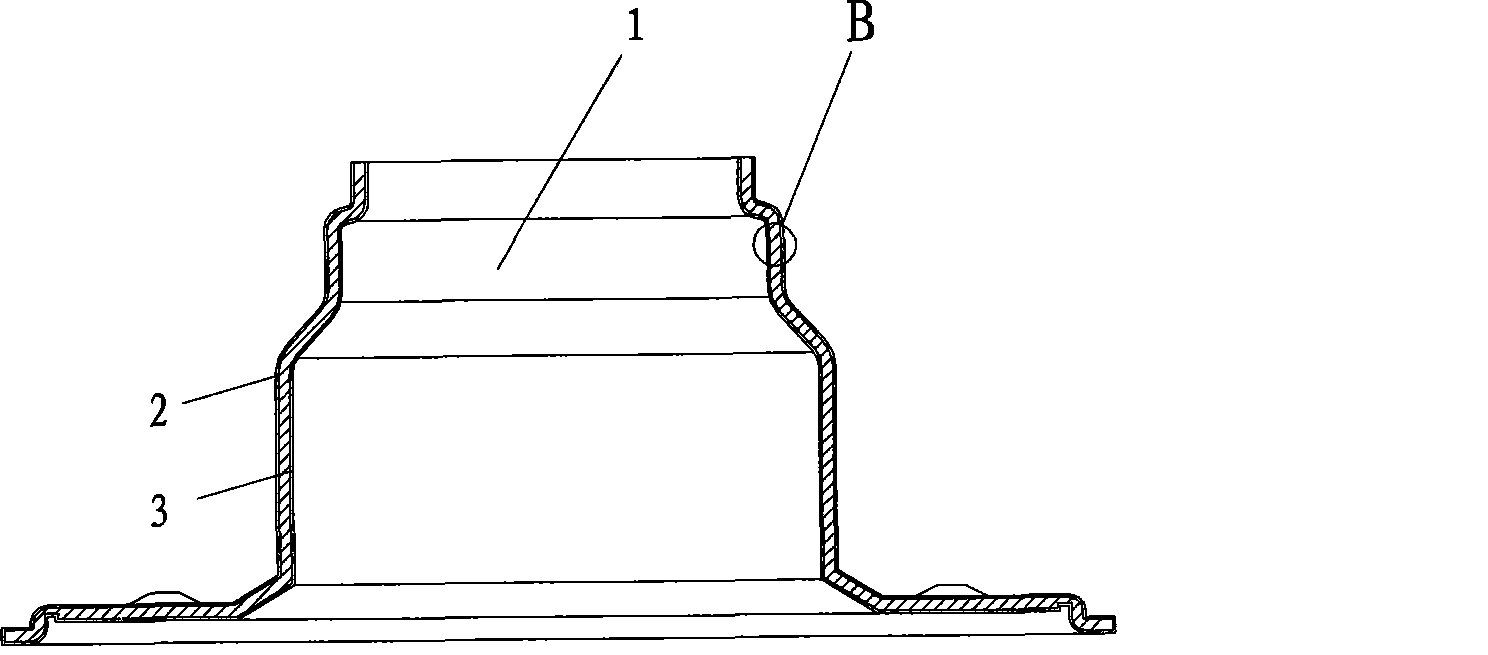

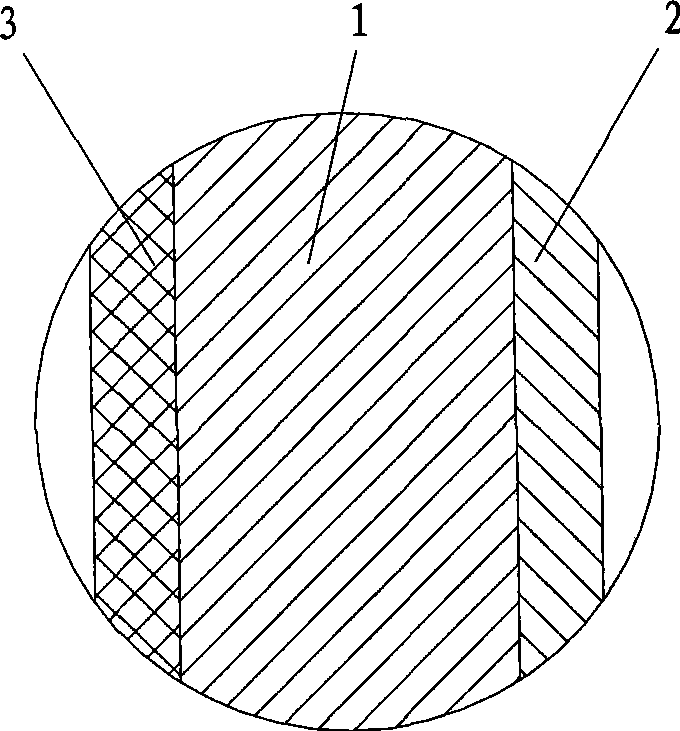

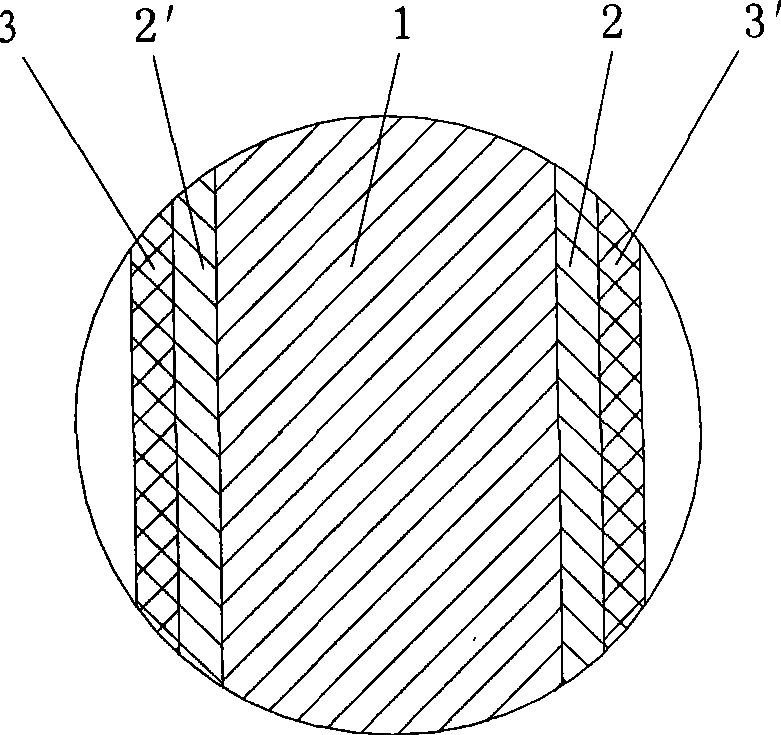

[0014] Because the skin effect of high-frequency wave causes current to flow through the inner surface of the magnetron shell, therefore, the shell of the magnetron of the present invention, such as figure 1 As shown, an outer nickel layer 2 is plated on the outside of the substrate 1 to prevent oxidation, and an inner copper layer 3 is plated on the innermost side of the substrate 1 to reduce heat loss caused by the skin effect. According to the difference of production equipment and production process, the structure of the magnetron shell of the present invention can be designed into the following two implementation modes.

[0015] Such as figure 2 Shown is the best embodiment of the present invention, since the inside of the magnetron tube core is in a vacuum state, under the premise of ensuring that the outer wall of the tube shell has strong oxidation resistance, it can be considered that the inner wall of the tube shell will not be oxidized situation. Therefore, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com