Ultra low voltae large caliber pulse blowing valve

A technology of pulse injection and valve cover, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. and other problems, to achieve the effect of cheap equipment, improved work ability, and increased injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

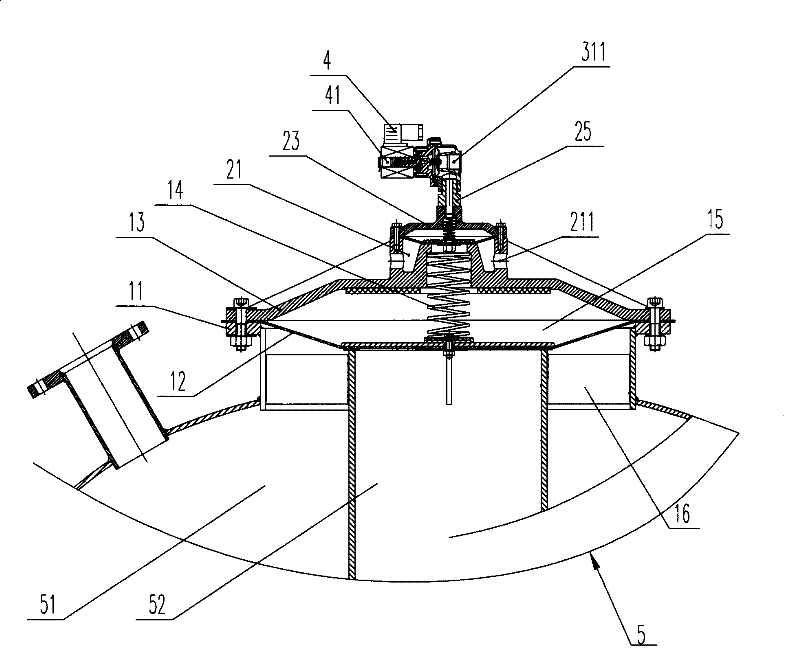

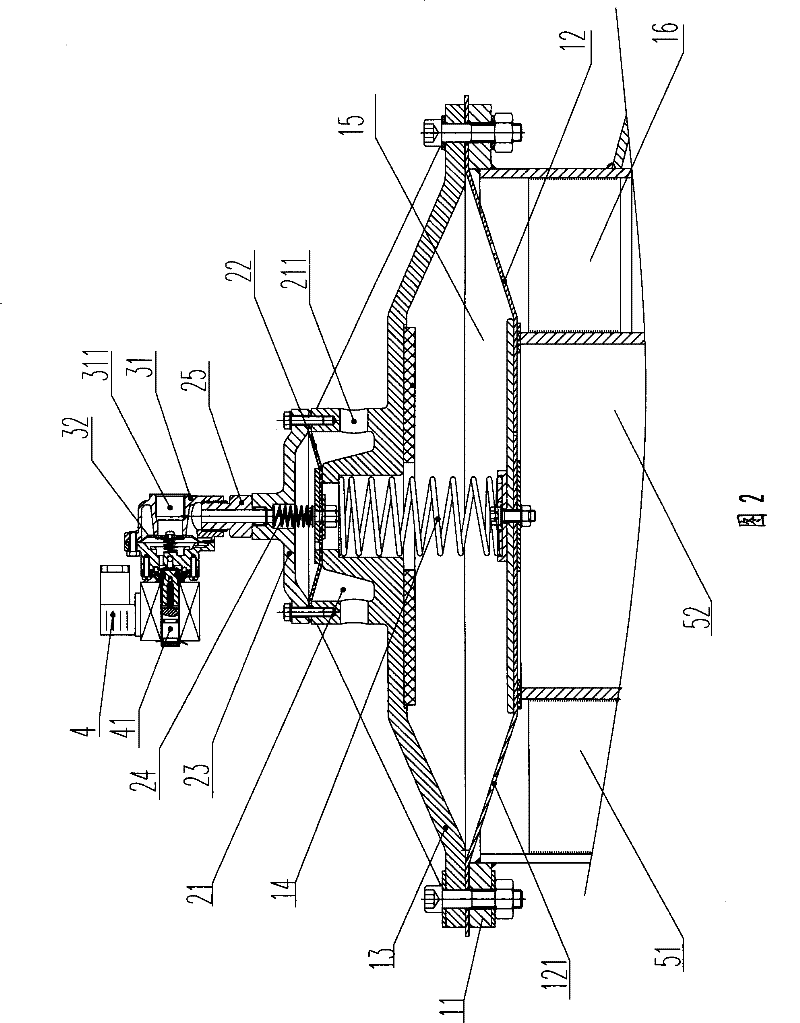

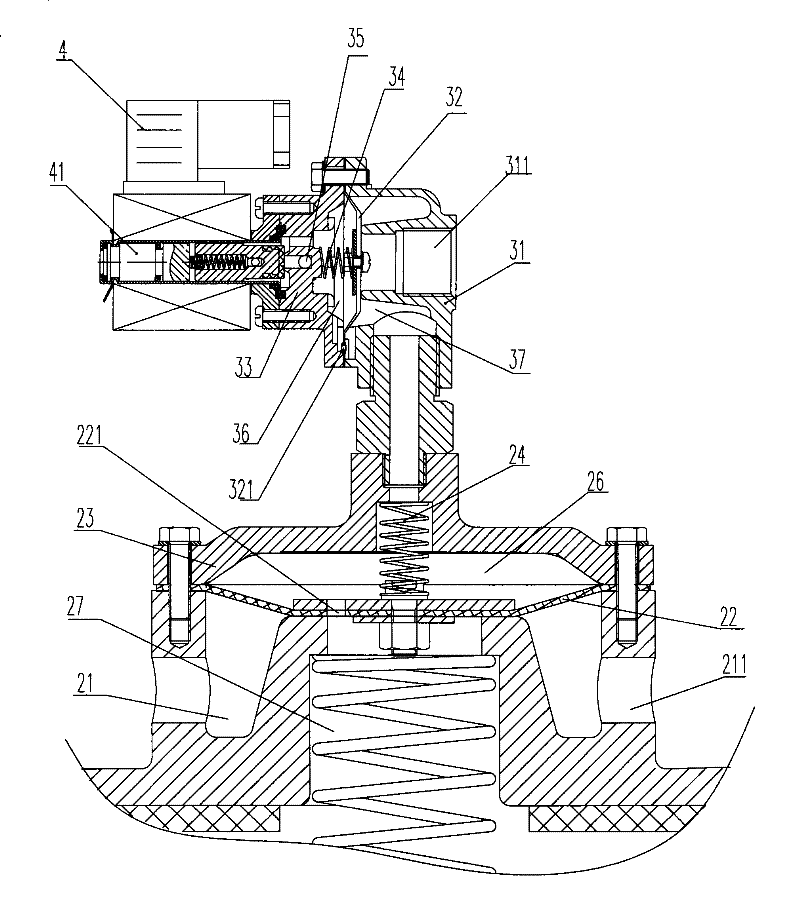

[0021] see attached figure 1 to the attached image 3 As shown in the figure, a pulse injection valve is composed of three-stage valve bodies arranged in series with each other.

[0022] The first-stage valve body includes: a first-stage valve body 11 fixedly connected to the air bag 5 of the pulse injection valve, a first-stage valve cover 13, and the first-stage valve cover 13 and the air bag. The primary diaphragm 12 between 5 and the primary spring 14 linked with the primary diaphragm 12, the primary diaphragm 12 separates the primary valve body into upper and lower The first-stage upper chamber 15 is enclosed between the first-stage diaphragm 12 and the first-stage valve cover 13 , and the space between the first-stage membrane 12 and the air inlet channel 51 of the air bag 5 The primary lower chamber 16 is enclosed, and the primary diaphragm 12 is elastically blocked on the exhaust passage 52 of the air bag 5 by the primary spring 14, and the primary diaphragm 12 is A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com