Wire-cut electric discharge machine and water level abnormality alarm generation cause specifying method

一种电火花线、切割机的技术,应用在电动加工设备、金属加工设备、附属装置等方向,能够解决易发生故障等问题,达到抑制停机时间、实现结构简单化、低成本化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

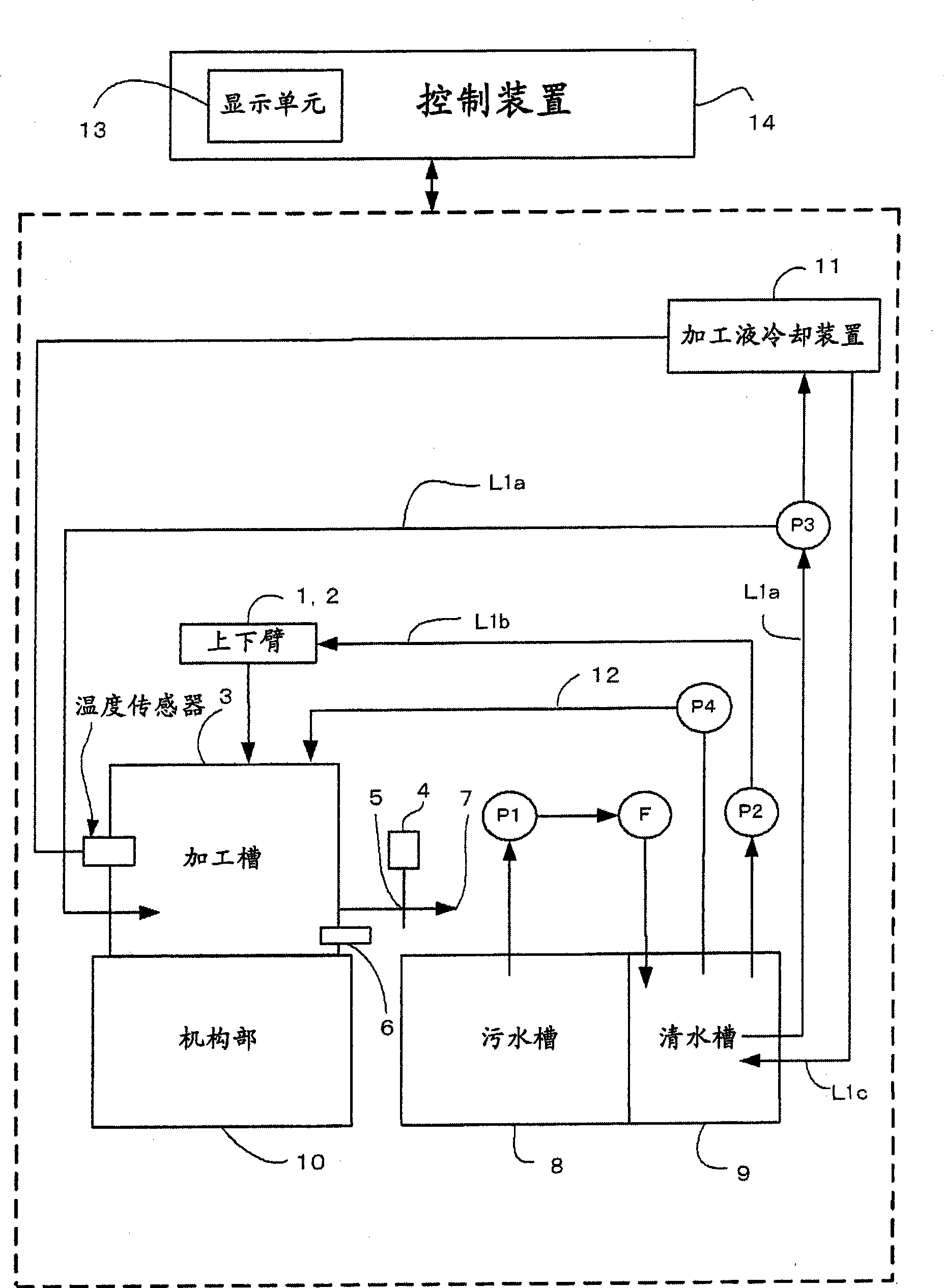

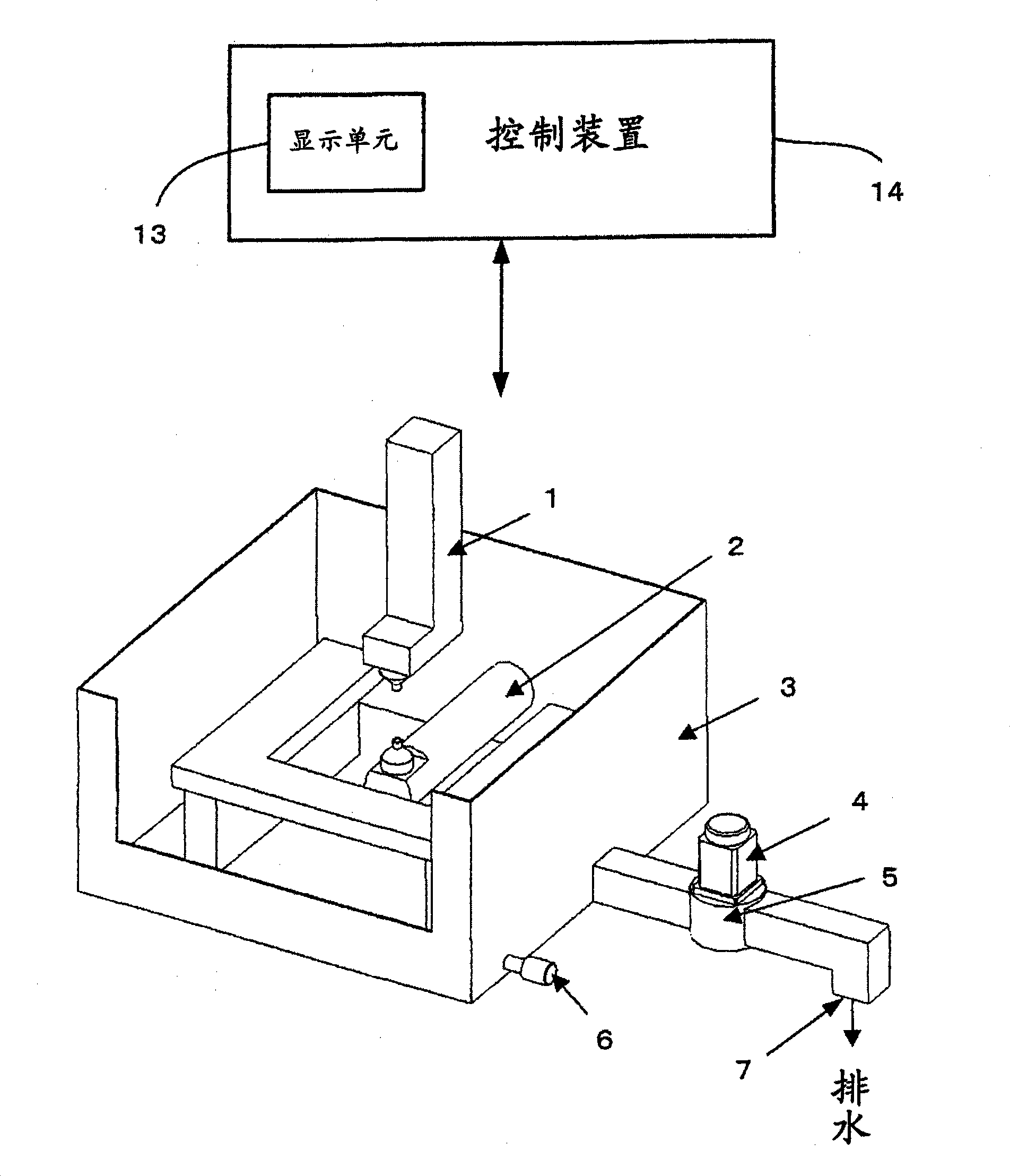

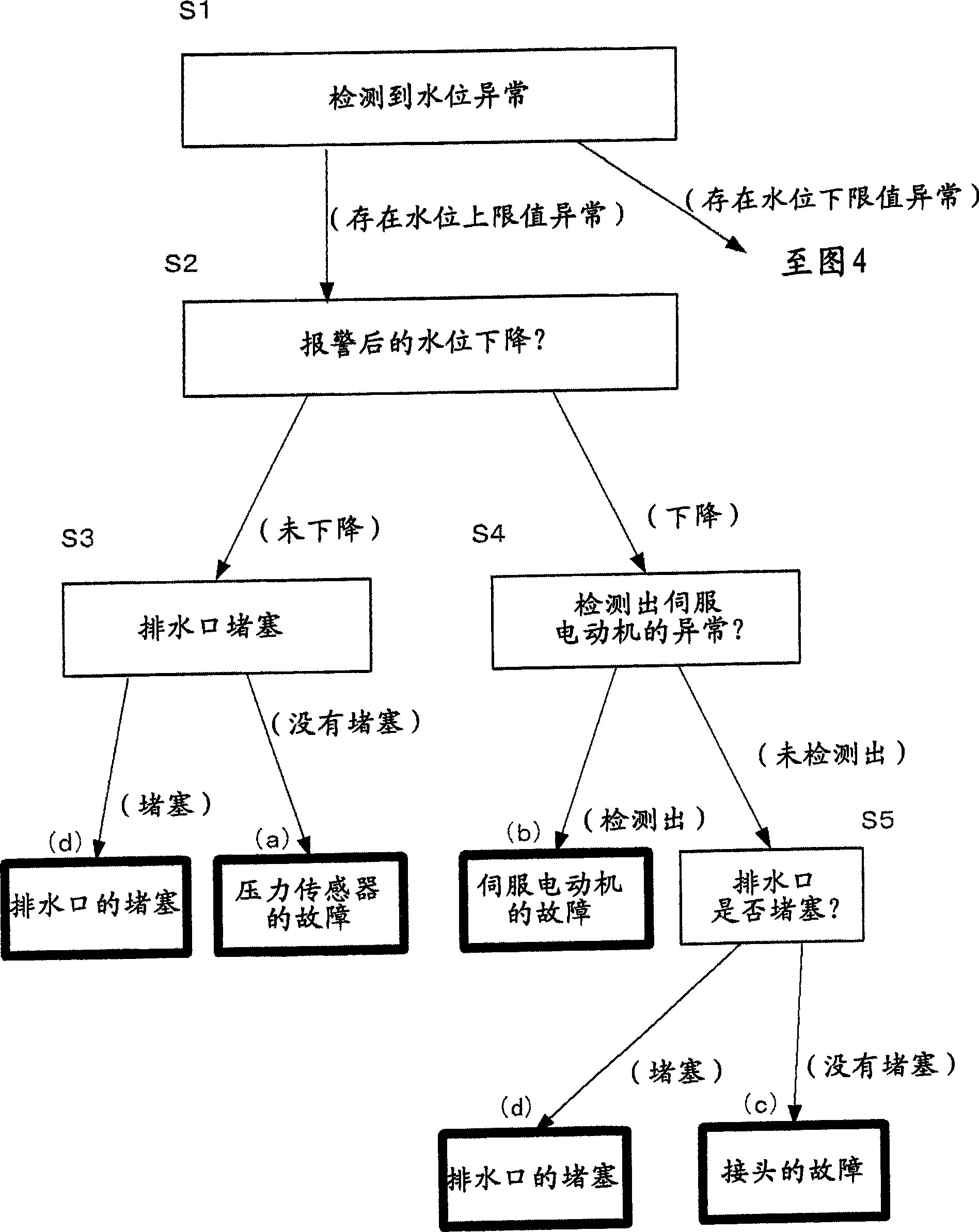

[0030] figure 1 It is a schematic block diagram showing one embodiment of the wire electric discharge machine of the present invention.

[0031] In the wire electric discharge machine, a voltage is applied between a workpiece placed and mounted on a table (not shown) provided on the mechanism part 10 and a wire electrode (not shown) to generate a discharge, and the wire electrode is opposed to the wire electrode. The workpiece is moved, whereby electrical discharge machining is performed on the workpiece. In addition, when rapidly accumulating the machining fluid in the machining tank 3 , it is performed through the rapidly accumulating machining fluid supply path 12 . Subsequent replenishment of the machining fluid is performed through the machining fluid supply path L1a. The machining fluid in the machining tank 3 is supplied to the waste water tank 8 mixed with machining debris and the like generated by electric discharge machining.

[0032] The machining fluid recovered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com