Measurement system for spraying urea liquid into exhaust flow in combustion engine

A technology of metering system and exhaust gas flow, applied in the field of metering system of selective catalytic reduction, can solve the problem of high fuel consumption of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

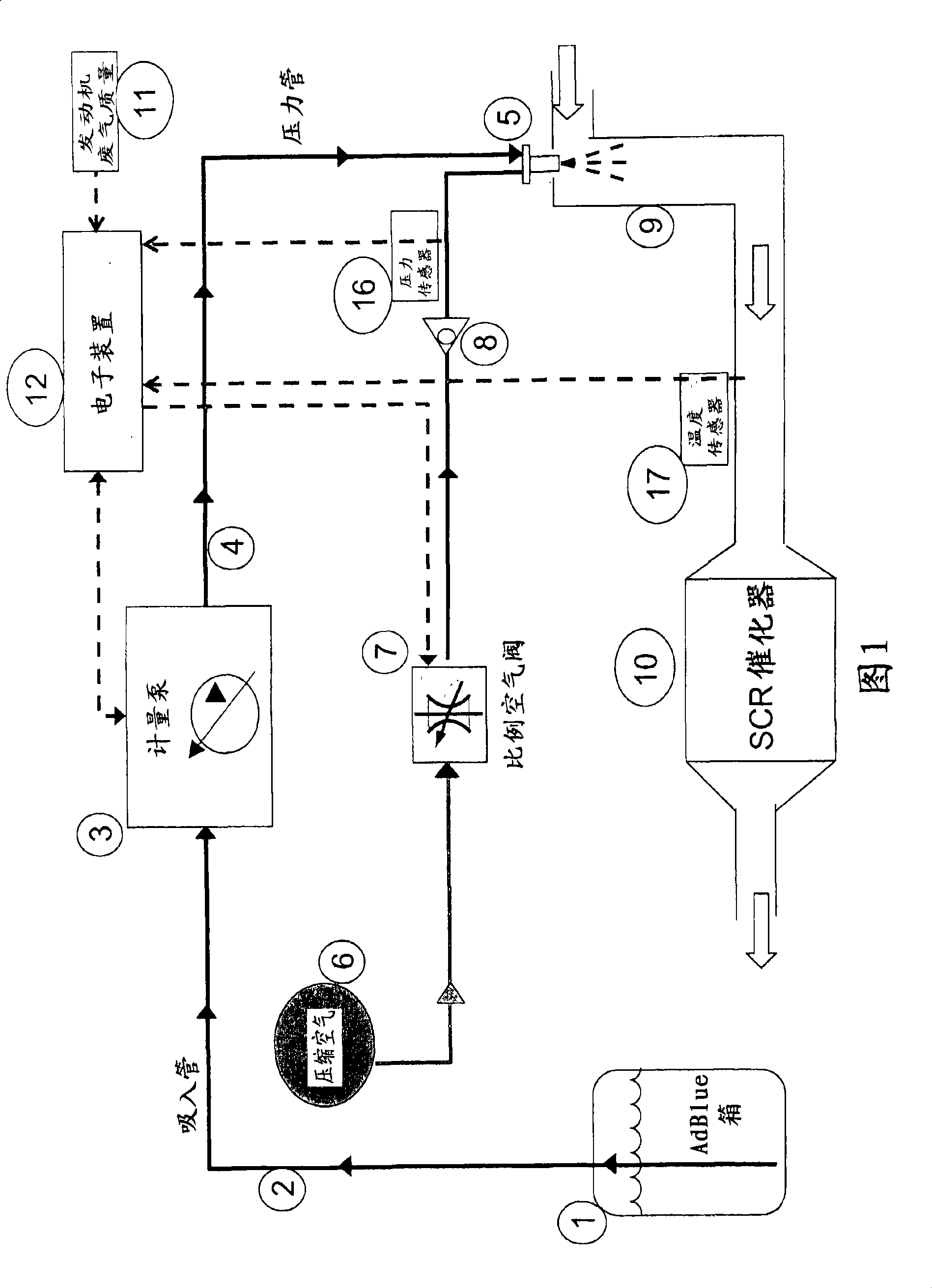

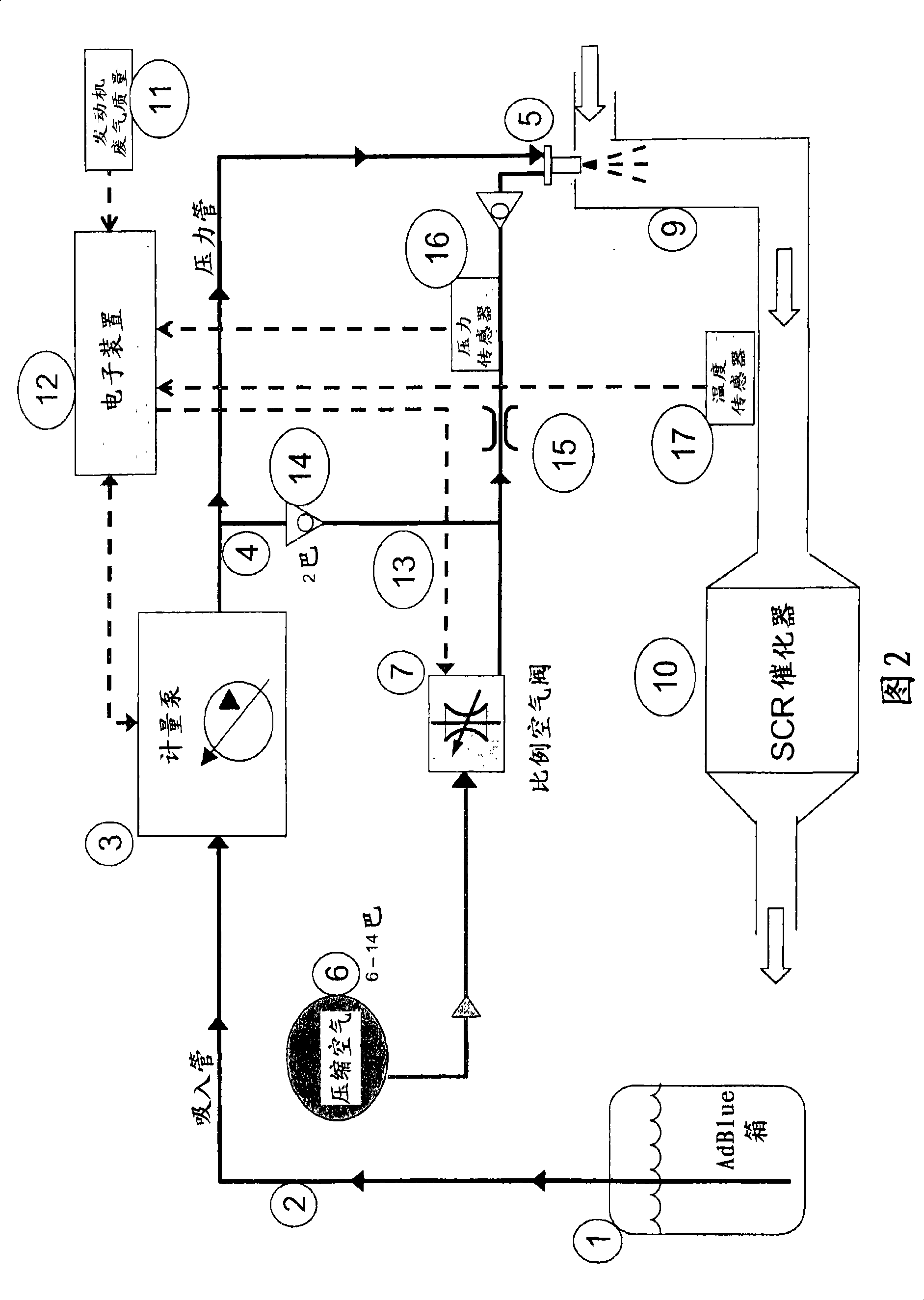

[0044] The same components and assemblies are shown with the same reference numbers in the figures. Figure 1 shows a schematic diagram of a first embodiment of a urea metering system.

[0045] The urea is sucked by the metering pump 3 from the tank 1 through the suction pipe 2 . The metering pump 3 is, for example, a diaphragm pump or a piston pump, which delivers a certain amount of urea solution with each stroke and thus likewise metered. The urea is delivered to the double-material nozzle 5 through the pressure pipe 4 . The dual-substance nozzle 5 is preferably an external mixing nozzle in which the air jet atomizes the urea.

[0046] Compressed air is delivered from the compressed air container 6 to the proportional air valve 7 . The proportional air valve 7 regulates the pressure flow to a value predetermined by the electronics 12 . The input parameters for calculating the values by means of the electronic control unit 12 are engine data, such as the exhaust gas mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com