Wafer quality analysis apparatus and method

A quality analysis device and quality analysis technology, applied in the direction of comprehensive factory control, instrumentation, comprehensive factory control, etc., can solve the problems of missing wafer process and incomplete analysis of wafer quality analysis methods, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

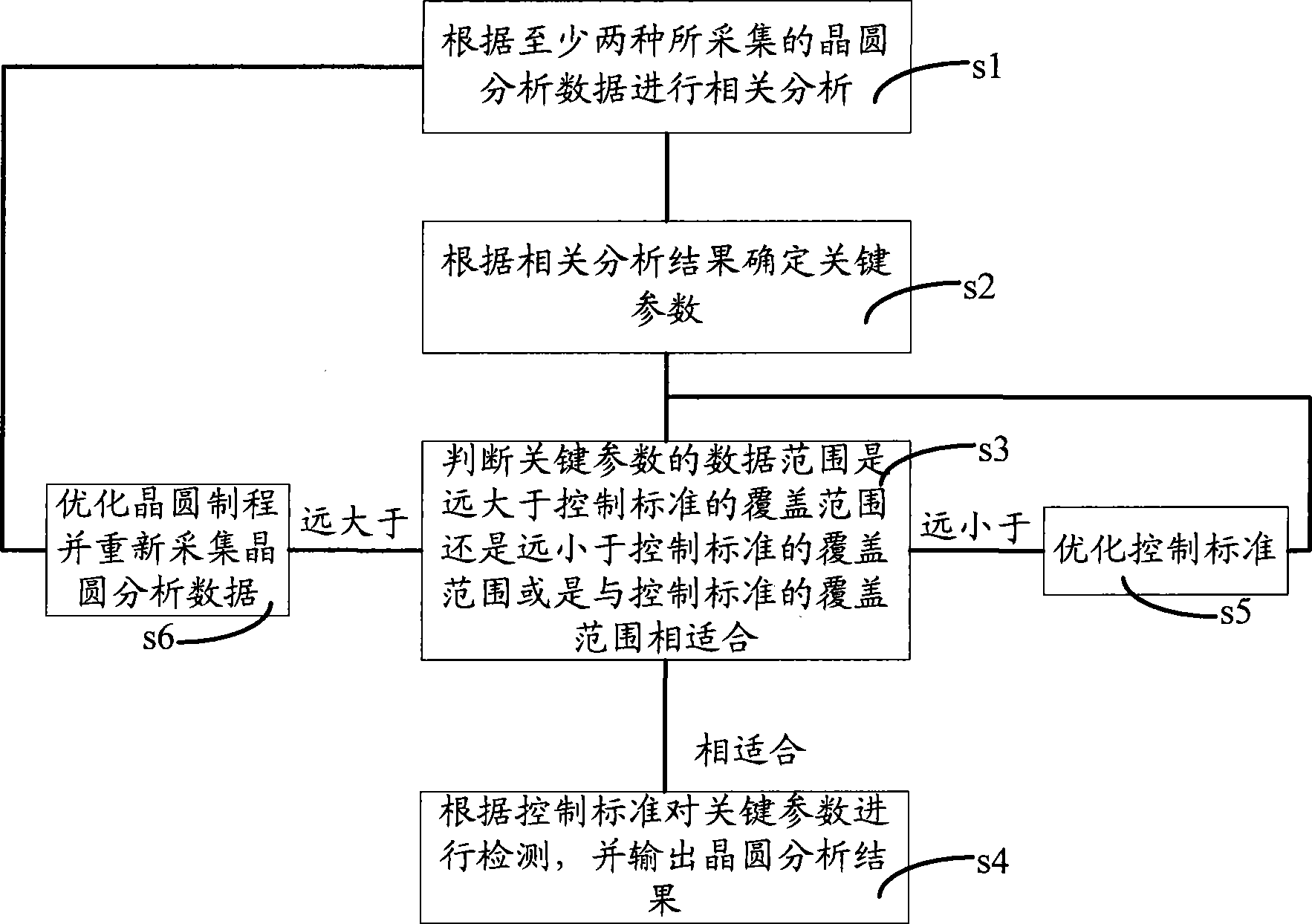

[0039] refer to figure 1 As shown, an embodiment of the wafer quality analysis method of the present invention comprises the following steps,

[0040] Step s1, performing correlation analysis according to at least two types of collected wafer analysis data;

[0041] Step s2, determining key parameters according to relevant analysis results;

[0042] Step s3, judging whether the data range of key parameters is much larger than the coverage range of the control standard, far smaller than the coverage range of the control standard or suitable for the coverage range of the control standard, if the data range of the key parameter is suitable for the coverage range of the control standard, Then execute step s4; if the data range of the key parameter is much smaller than the coverage of the control standard, then execute step s5; if the data range of the key parameter is far beyond the coverage of the control standard, then execute step s6;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com