Electronic counting method of electromechanical counter and counter employing the method

A counting method and counter technology, applied in the field of measurement, can solve the problems of high power consumption, lack of reliability and manufacturing cost, accumulation of measurement errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

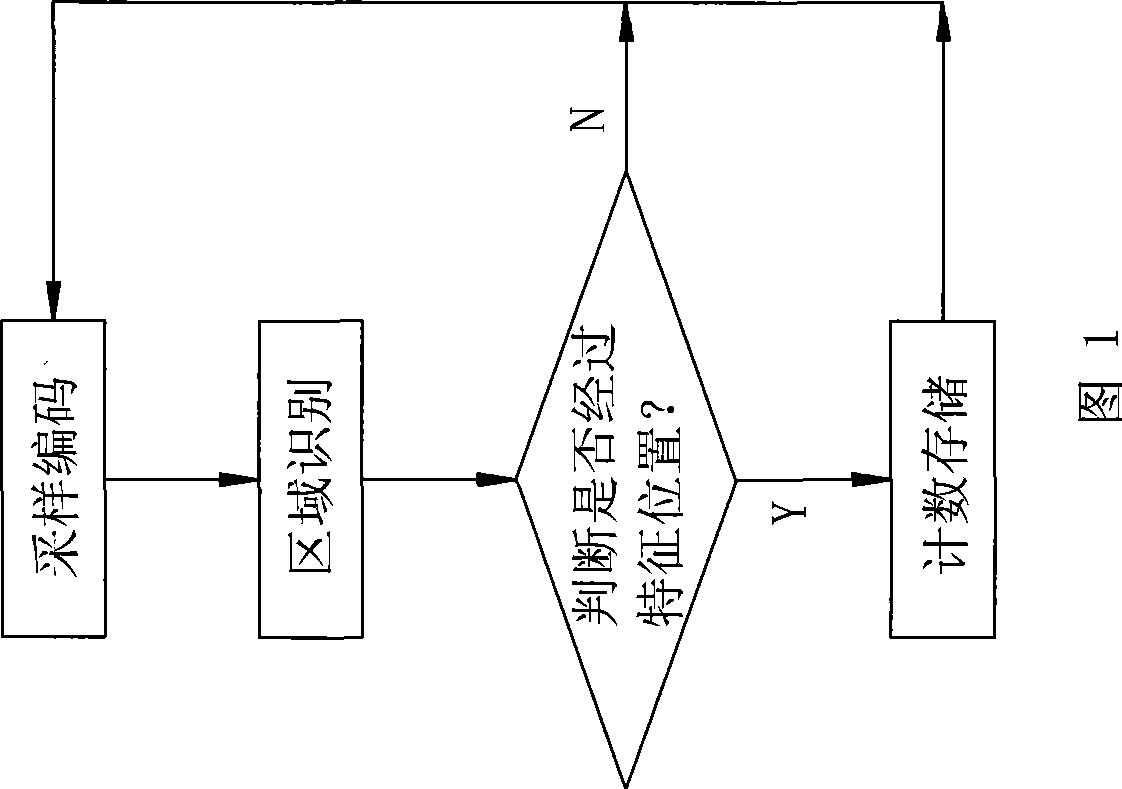

[0083] An electronic counting method for an electromechanical counter as shown in Figure 1, a coding structure is set on a character wheel of the electromechanical counter as a sampling character wheel, and the electronic system reads the code through a correspondingly arranged sensor and can convert the sampling character wheel The circumference area is divided into at least two arc areas with different codes, and at least one of the arc areas is used as the characteristic position counted by the electronic system. The working steps of the electronic system are as follows:

[0084] 1) Sampling code, the sensor samples according to a fixed sampling period;

[0085] 2) Area identification, the electronic system identifies the arc area corresponding to the sensor during this sampling through the sampling code;

[0086] 3) Judgment counting, the electronic system compares the arc area corresponding to the sampling sensor this time with the arc area corresponding to the previous s...

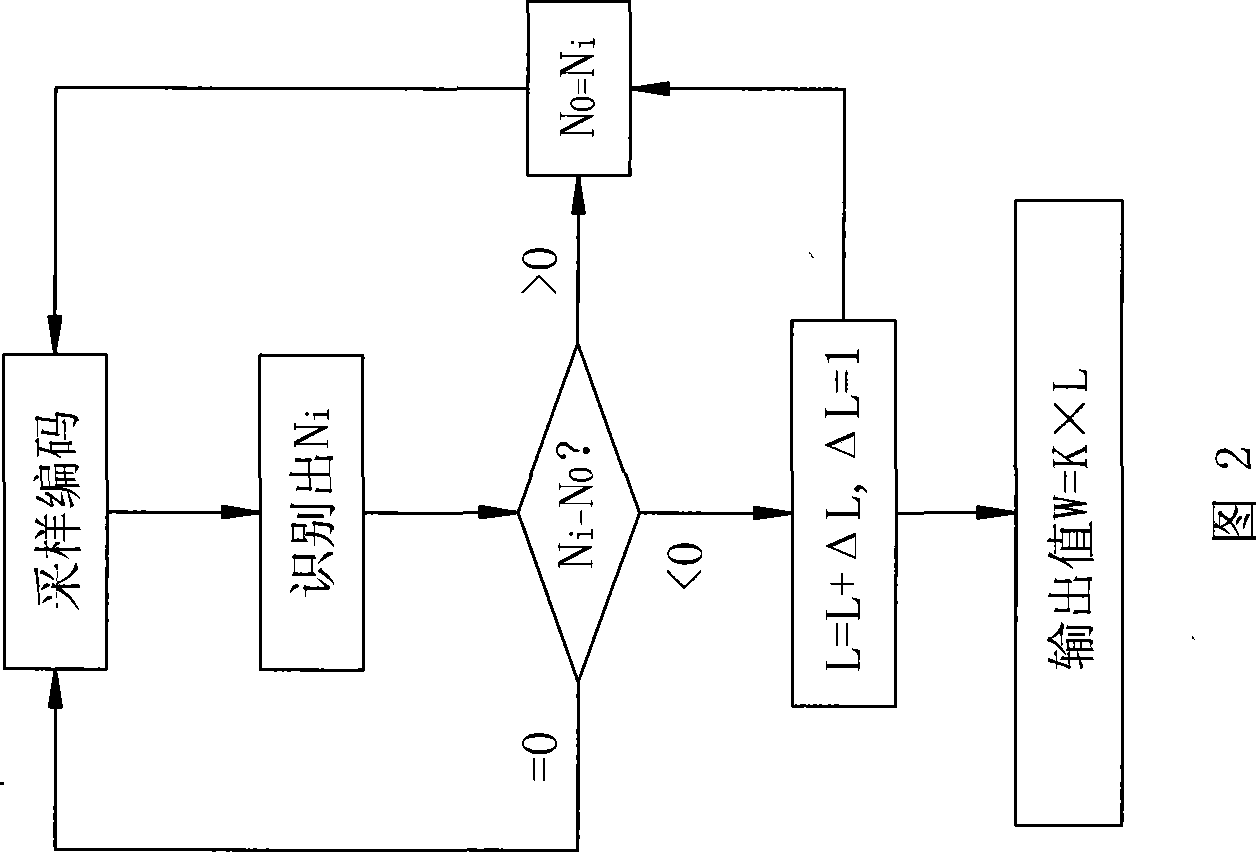

Embodiment 2

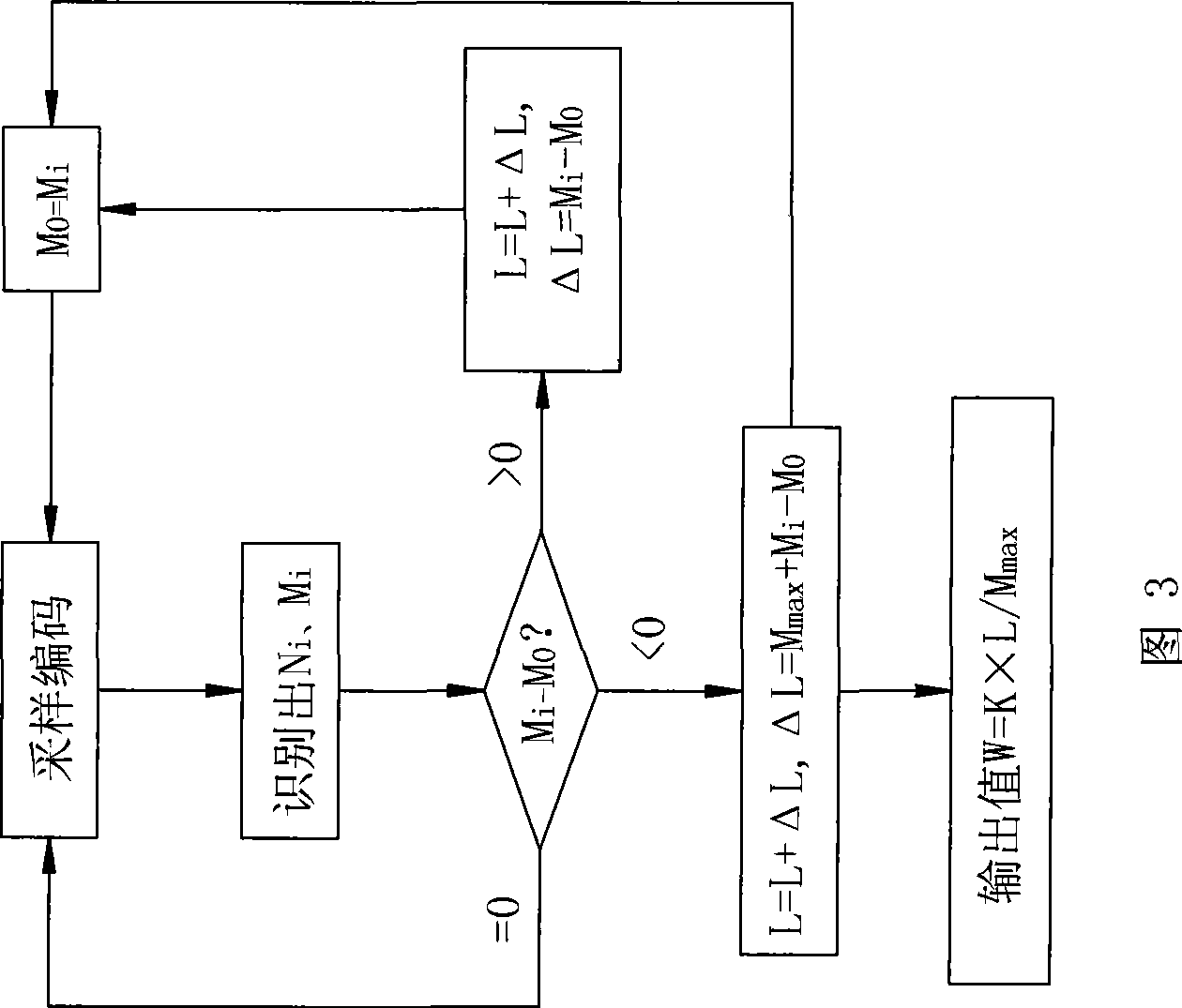

[0091] The electronic counting method of a kind of electromechanical counter as shown in Fig. 1, Fig. 3, and the difference of embodiment 1 is that the circumference of above-mentioned sampling character wheel is divided into at least 10 section arc areas, 10 arc areas wherein Set as the characteristic position, and make each characteristic position correspond to ten digital positions on the cylindrical surface of the sampling character wheel, the single measurement value of the electronic system in the step 3) is the time passed by the rotation of the sampling character wheel The product of the number of characteristic positions and the physical quantity measured by the rotation of one tenth of the sampling wheel.

[0092] The workflow of the electronic system is shown in Figure 3. The above-mentioned electronic system assigns each segment of the arc area a sequence number in sequence (that is, when the sampling character wheel rotates, each segment of the arc area that appear...

Embodiment 3

[0094] like Figure 4 , Figure 5 The shown electromechanical counter adopts the above method, which includes a housing 7, a character wheel shaft 1, several ordinary character wheels 2 with numbers printed on several cylinders, a carry gear 9, a carry gear shaft 8, and a sampling character wheel 5. The sampling character wheel 5 and the ordinary character wheel 2 are carried through the mechanical transmission of the dial 3. The sampling character wheel 5 is provided with a coding structure, and the housing 7 is provided with a sensor 4 corresponding to the coding structure. The sensor 4 Connect the electronic system; the above coding structure is arranged on the sampling character wheel 5 end faces and is used to distinguish some circular ring code tracks 51 of the sampling character wheel arc area, and the circular ring code tracks 51 are composed of some transparent segments and non-permeable segments distributed alternately. The above-mentioned sampling word wheel 5 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com