Quality management transversal integration system and method

A quality management and horizontal technology, applied in the data integration system field of enterprise product quality management, can solve problems such as comparison and evaluation problems, constraints on process improvement, product process improvement, and inability to count product quality data, so as to improve the decentralized situation and expand flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

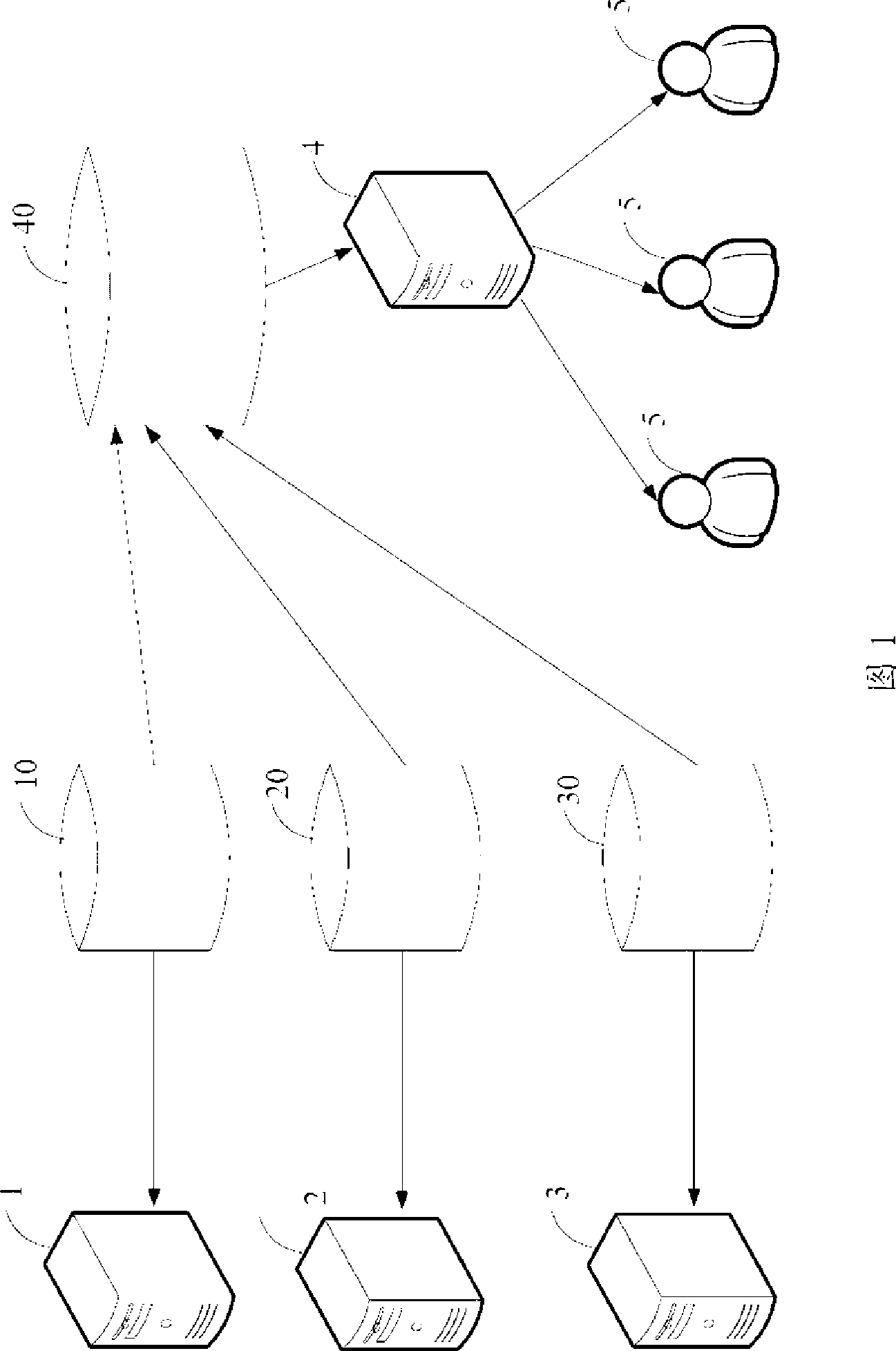

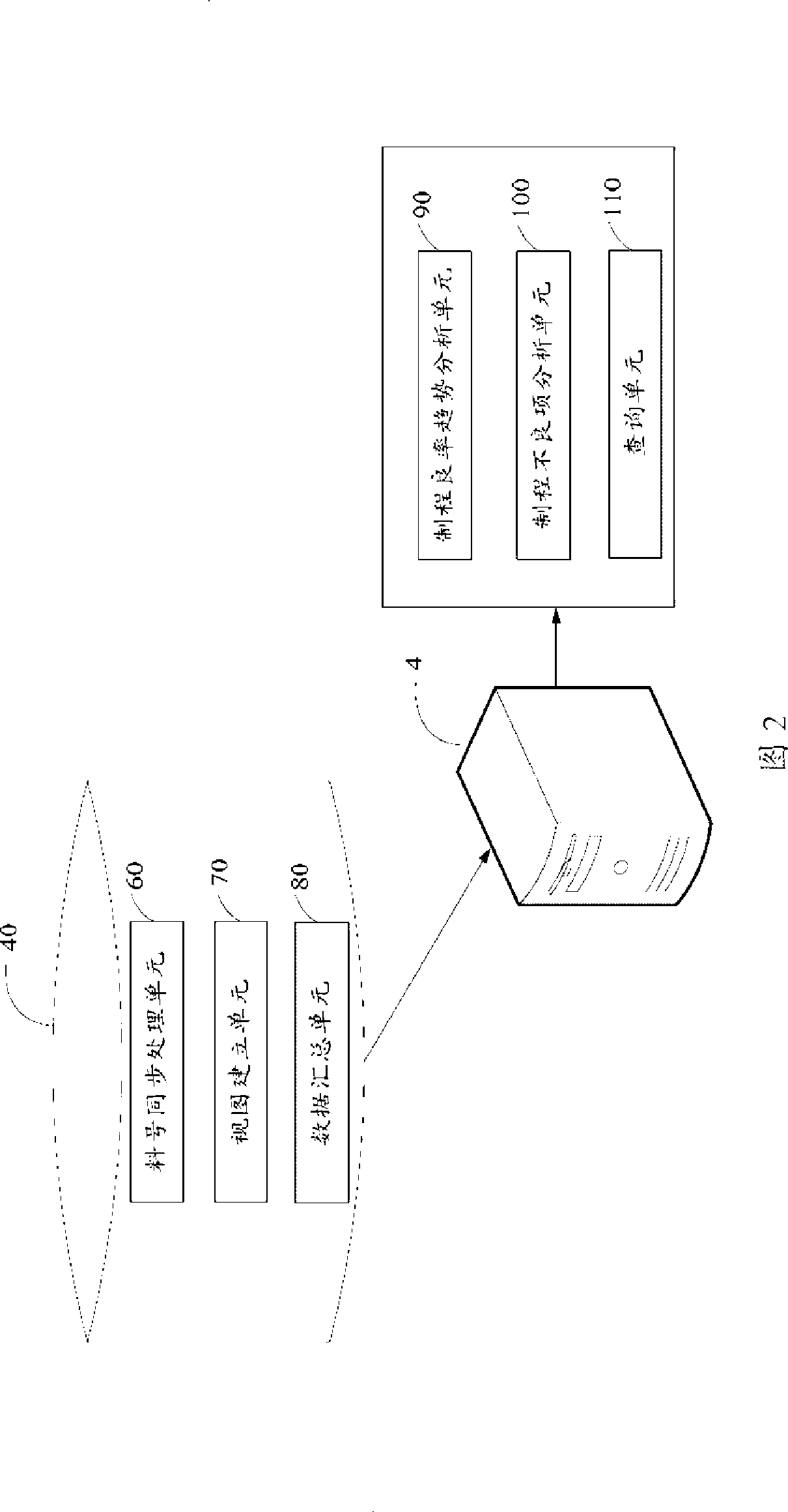

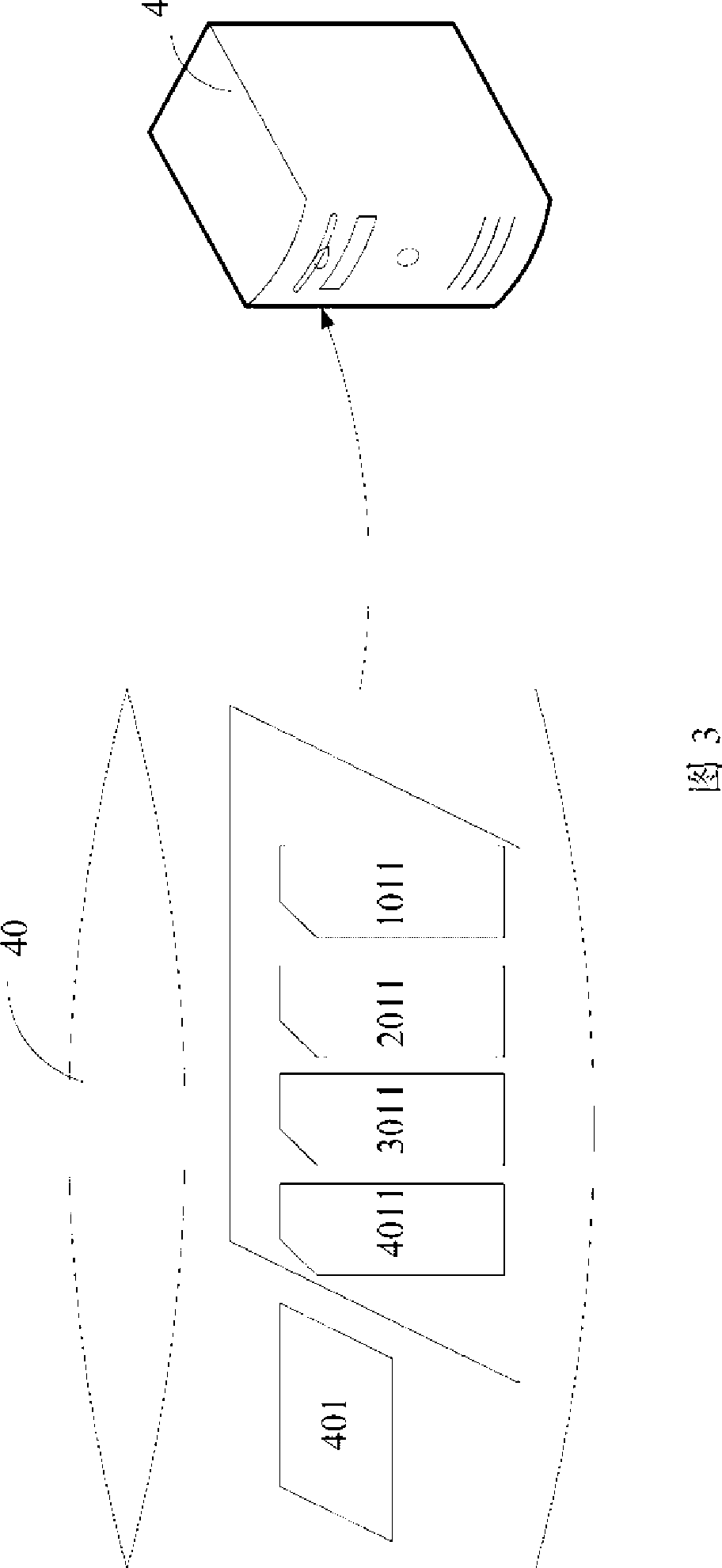

[0010] As shown in FIG. 1 , it is a hardware architecture diagram of a preferred embodiment of the quality management horizontally integrated system of the present invention. The system includes an area database 10 located in area A, an area database 20 located in area B, an area database 30 located in area C, and an area database 40 located in area D. Wherein, the area database 10 corresponds to the web server 1 located in area A, the area database 20 corresponds to the web server 2 located in area B, the area database 30 corresponds to the web server 3 located in area C, and the area database 40 corresponds to the web server 4 located in area D.

[0011] In this preferred embodiment, assuming that the D region database 40 is used as an integrated database, the product quality data in the A, B, and C region databases are finally summarized in the integrated database, and the management personnel in charge of the production quality of the enterprise can connect to the integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com