Measuring water vapor in hydrocarbons

A hydrocarbon, water vapor technology, used in measurement devices, optical radiation measurement, color/spectral property measurement, etc., to solve problems such as sensor uselessness, delay in wetting and drying, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

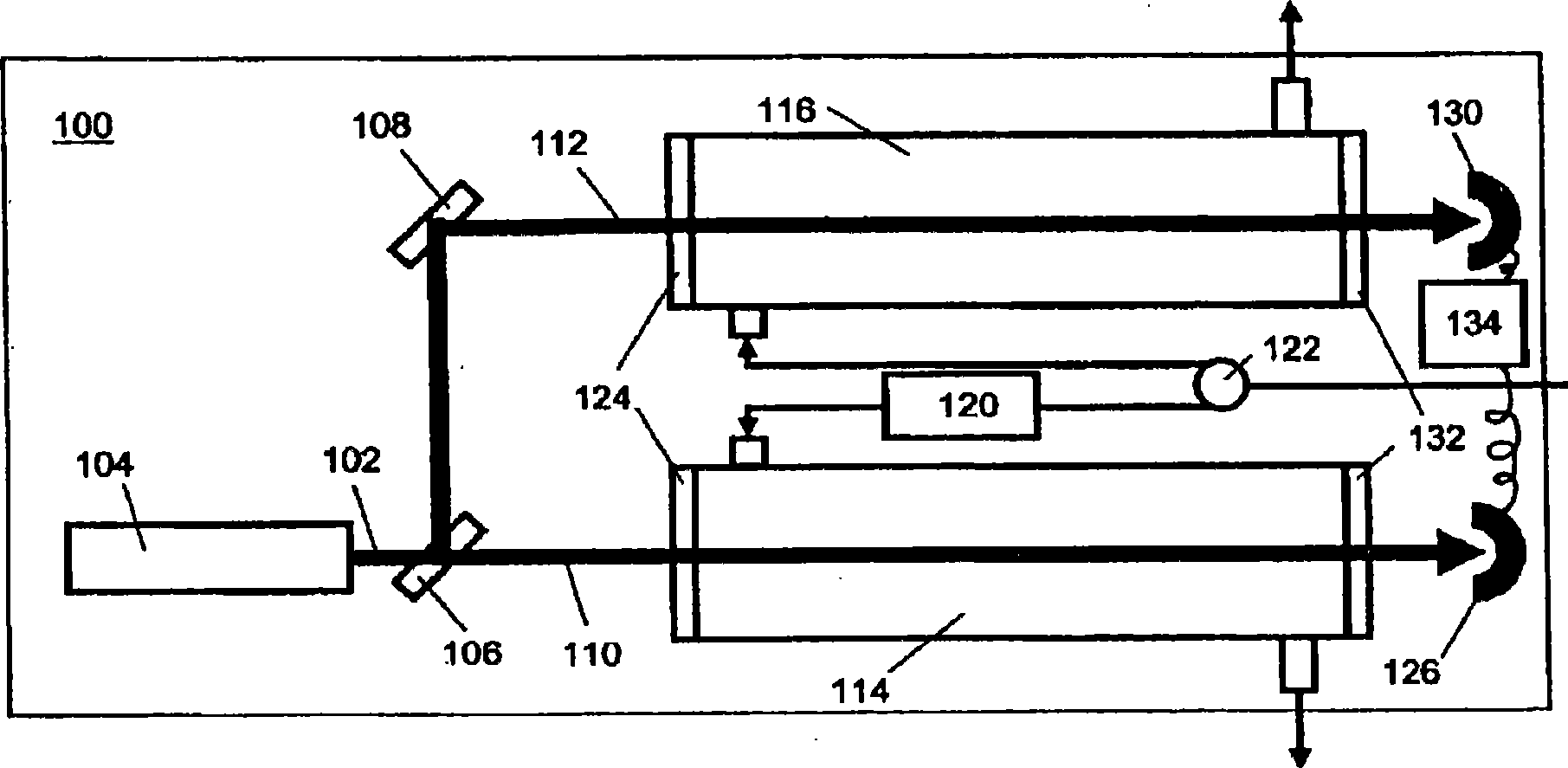

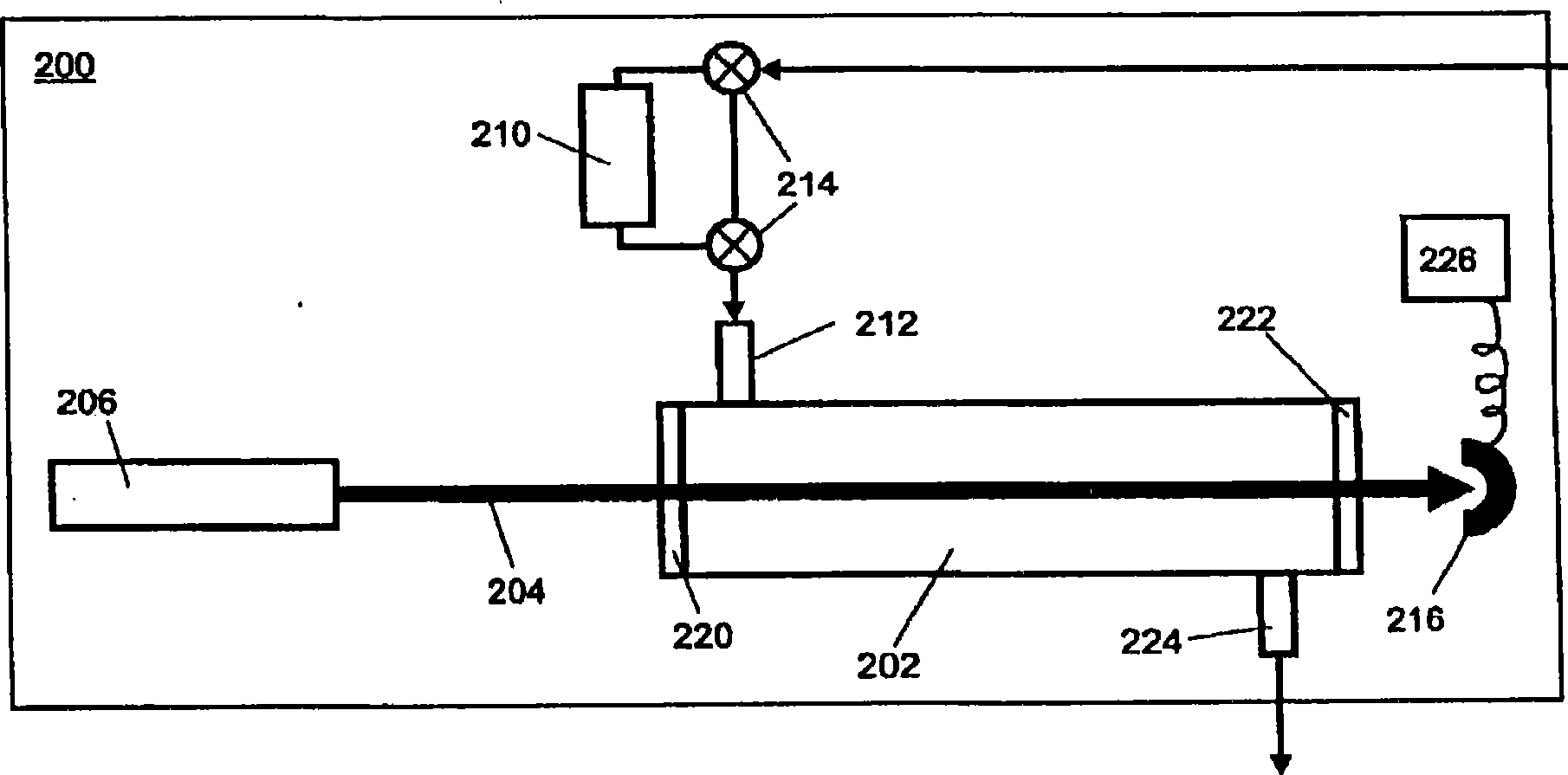

[0104] [0065] Using the techniques and spectrometer described herein, yield Figure 13 The curve shown for water vapor in ethylene at a partial pressure of 500 mBar, Figure 14 The curve shown for water vapor in propylene at a partial pressure of 250 mBar, and Figure 15 Curve shown for water vapor in isobutane at a partial pressure of 300 mBar. For each example shown, use the same figure 2 The structure of the sample chamber shown is similar to that of a single sample chamber. A tuned laser operating at approximately 2735 nm provides the incident light. The laser pulse cycle period was approximately 263 milliseconds, and the temperature of the spectrometer was controlled by placing the spectrometer in a thermally controlled cabinet maintained above 30°C with an accuracy of approximately ±0.1°C.

[0105] [0066] The results of these examples demonstrate that ≤ 500 ppb H in gas mixtures containing olefins 2 Renewable amount of O. For ethylene, an absorption chamber with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com