Equipment for finishing aligning, end-cutting and hole-punching at one time after rolling single end of vehicle plate spring

An automobile steel plate and straightening technology, which is applied in the direction of metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of many processing steps, inconvenient automation, and high labor intensity, so as to reduce process transfer, realize automation, and reduce The effect of heating times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

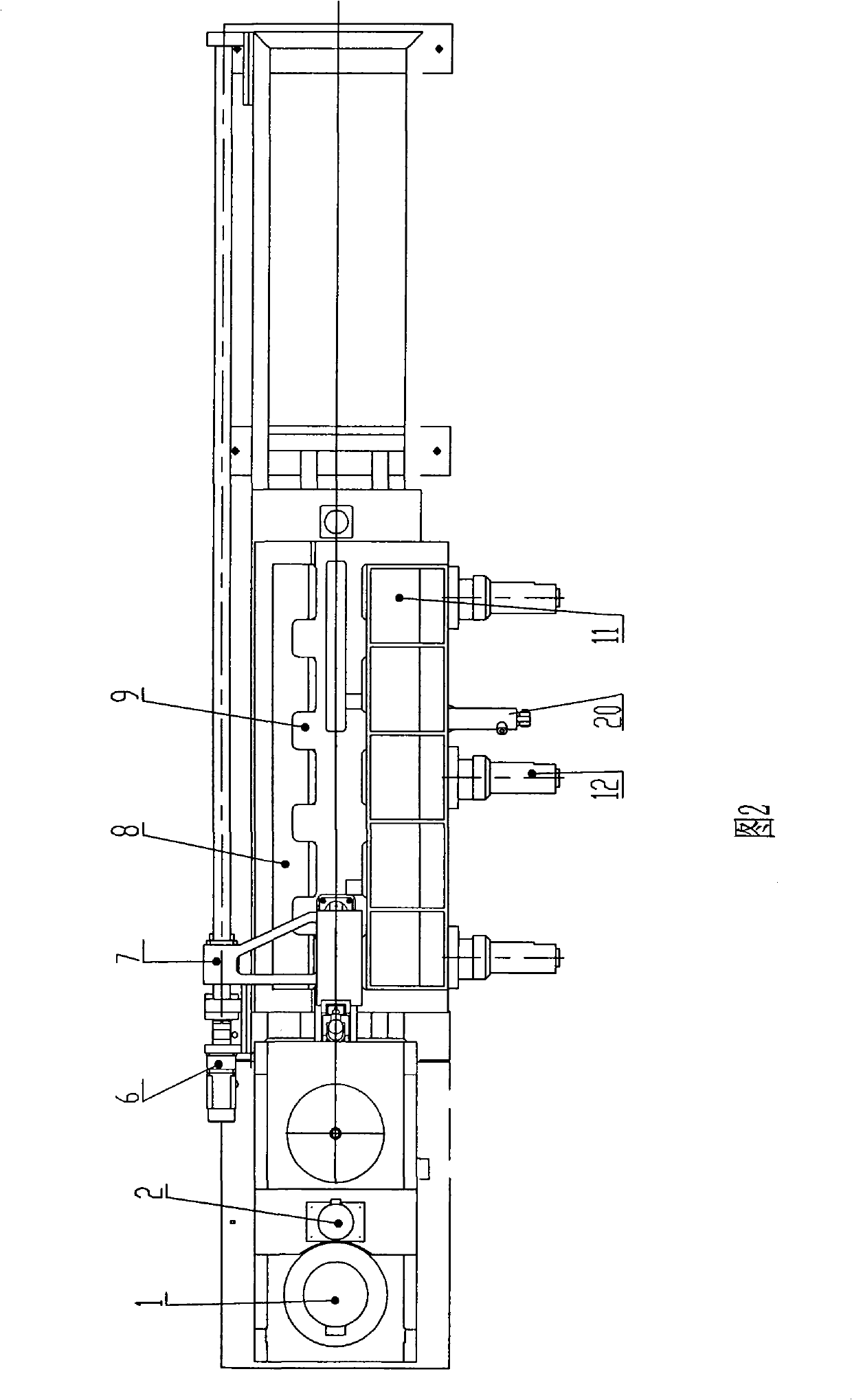

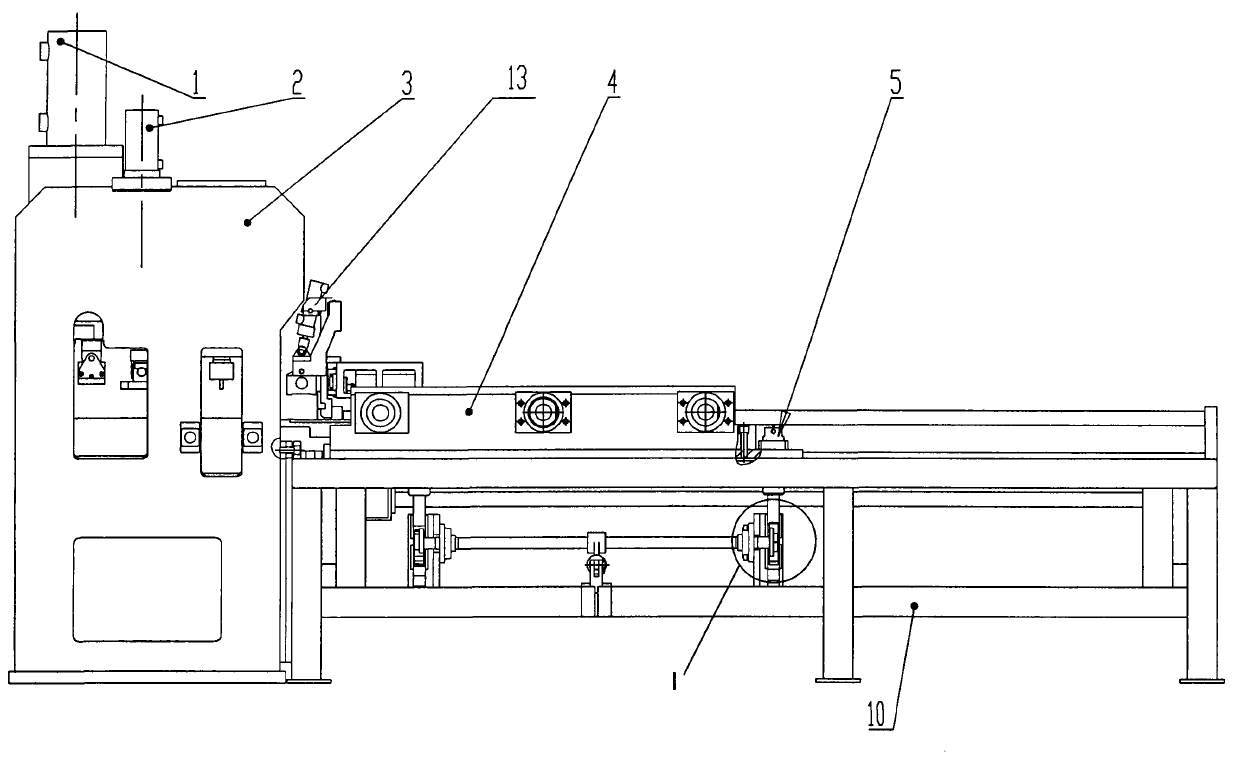

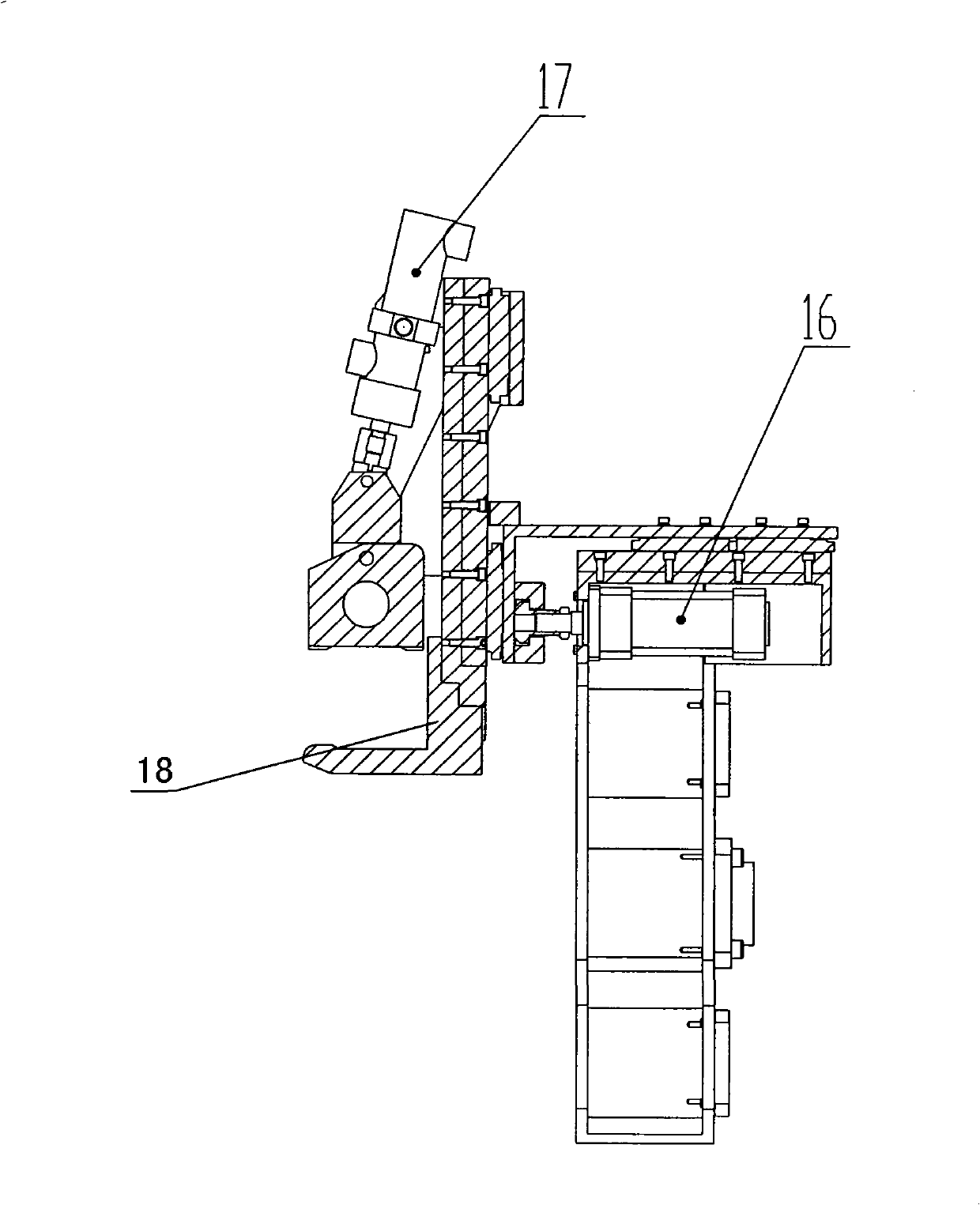

[0022] As shown in the figure, the equipment is composed of five major parts: a press 3 , a straightening mechanism 4 , a lifting table 9 , a length positioning mechanism and a frame 10 . Press machine 3 is positioned at the front end of equipment, and head cutting cylinder 1 and punching center hole cylinder 2 are housed on press machine 3. The frame 10 is located at the rear end of the equipment and is connected with the press 3 . A straightening mechanism 4 is installed near the end of the press 3 on the frame 10. The straightening mechanism 4 is composed of a straightening oil cylinder 12, a slide block 11 and a fixed block 8. The straightening oil cylinder 12 is connected with the slide block 11, and the fixed block 8 is connected with the frame. 10 connection, the slider 11 and the fixed block 8 are relatively parallel arranged along the center line of the equipment, and the straightening cylinder 12 drives the slider 11 to move, so that the reed is clamped between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com