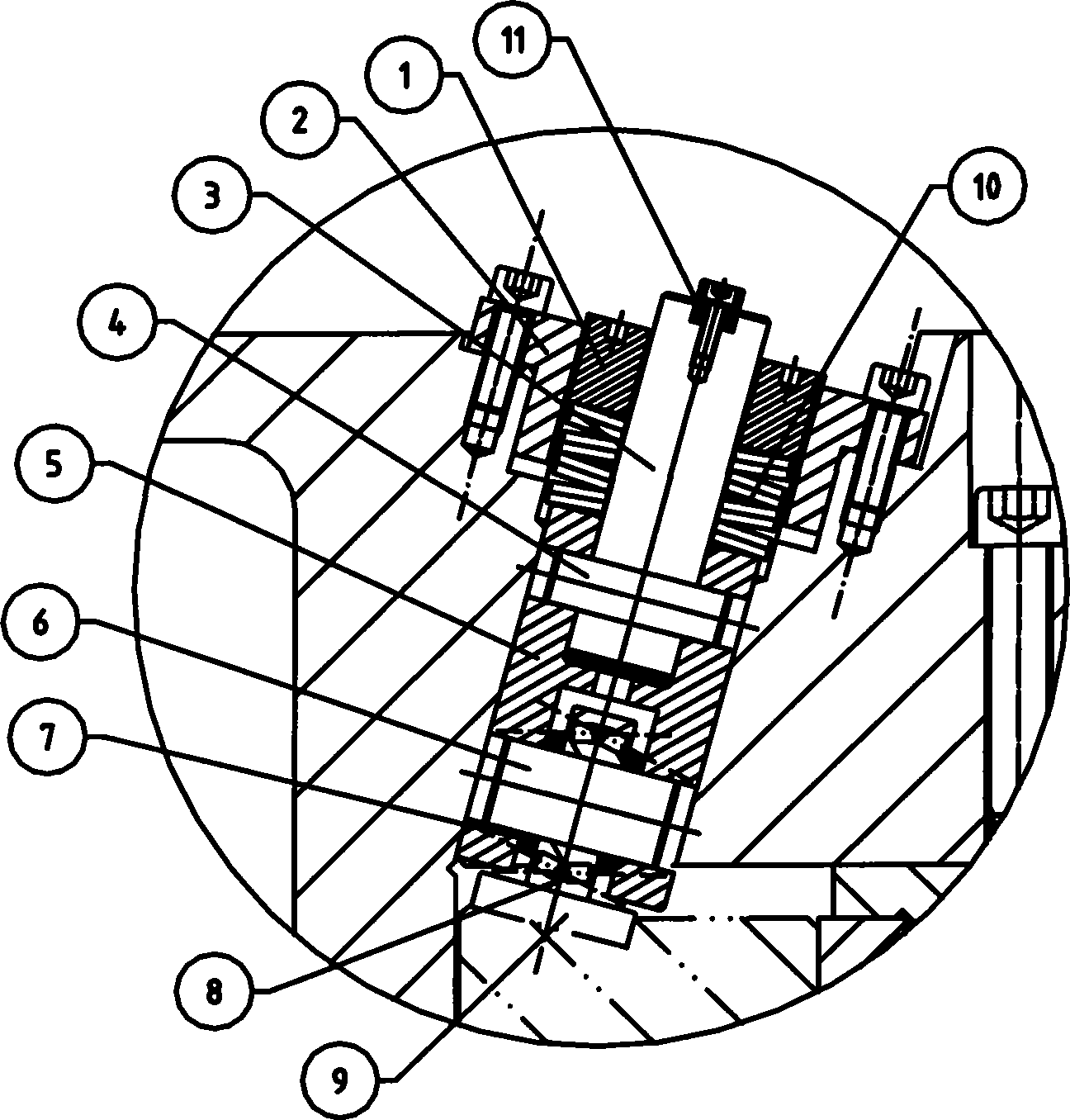

Guide rails unloading gear for transverse slide carriage

An unloading device and sliding plate technology, applied in the field of machine tools, can solve the problems affecting the accuracy of the machine tool, the deformation of the guide rail, and the wear of the inserts, and achieve the effects of improving the precision of the machine tool, reducing the deformation of the beam, and reducing the wear of the inserts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate understanding of the content of the present invention.

[0013] exist figure 1 Among them, the T-shaped sleeve 2 is fixed on the horizontal slide plate as the focus of the whole mechanism. The nut 1 is connected to the T-shaped sleeve 2 through threads, and the bearing bracket 5 is matched with the inclined hole of the horizontal slide plate to play a guiding role and adjust the center. The roller bearing 8 is fixed on the bearing bracket 5 through the shaft 6, the self-aligning roller bearing 8 is positioned with the sleeve 7, the guide shaft 3 is fixed on the bearing bracket 5 through the shaft 4, and the general-purpose disc spring 10 is installed on the nut 1 and Between the bearing brackets 5, the same two sets of mechanisms are positioned by the key 11 to prevent deflection, and the compression amount of the general-purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com