Pneumatic tire and configuration for reducing a tire noise

A technology of pneumatic tires and tires, which is applied in the direction of transportation and packaging, tire parts, wheels, etc., can solve the problems of increasing cost and time, must be replaced, and pneumatic tires can no longer be repaired, so as to avoid assembly costs and time spent , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

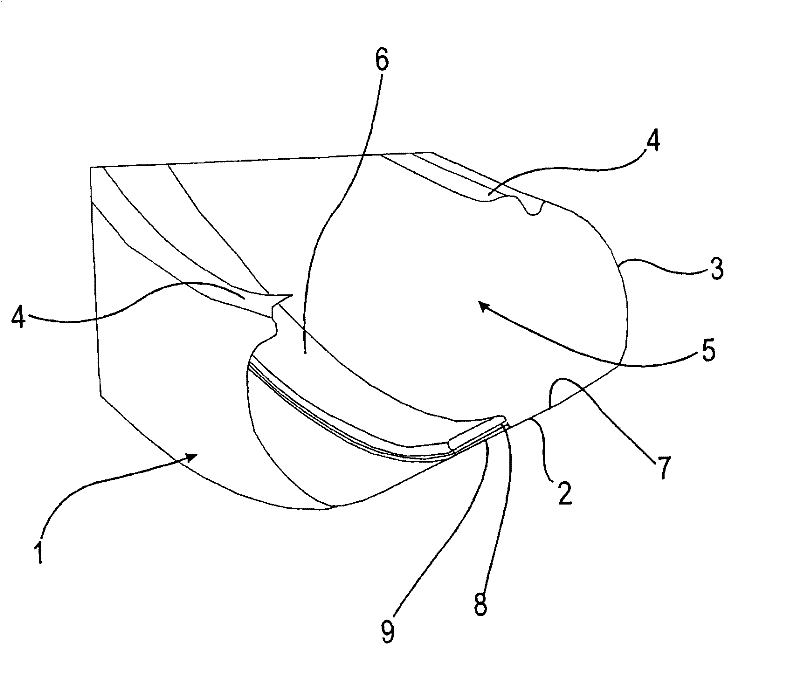

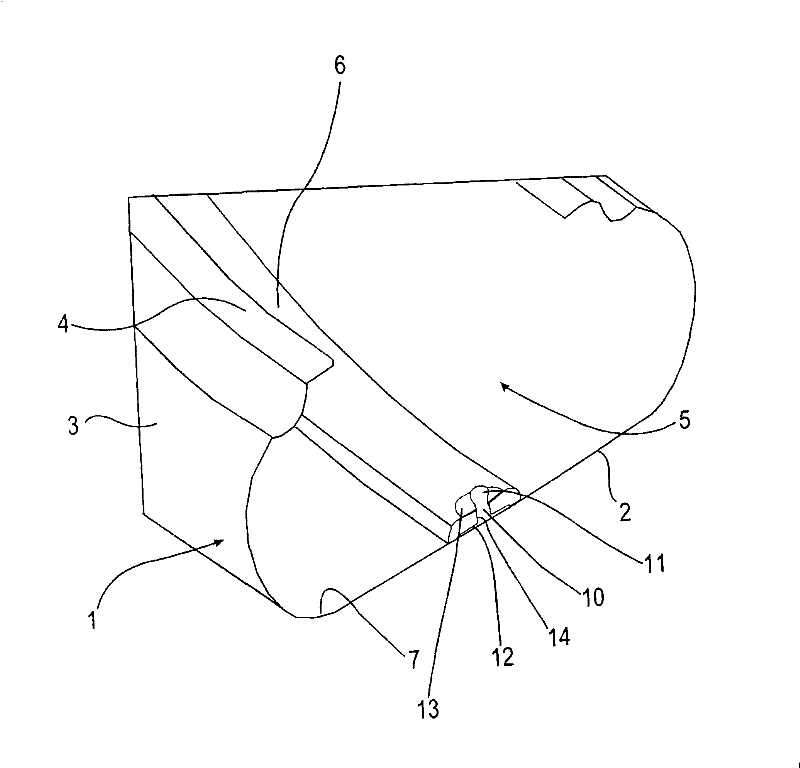

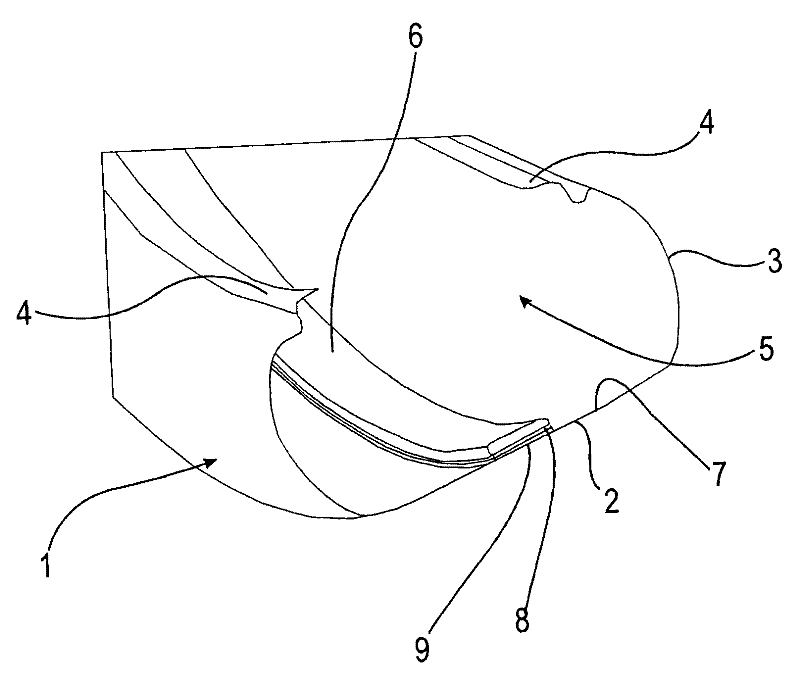

[0024] first look at figure 1 , which schematically represents a partial cutaway perspective view of a first embodiment of a tubeless pneumatic tire for automobile wheels according to the present invention. The pneumatic tire generally designated with the reference numeral 1 comprises a tread portion 2 radially on the outside for the rolling of the pneumatic tire 1 on roads, two sidewall segments 3 and two radially inward bead Segment 4, when the pneumatic tire is mounted on the rim and then inflated, the bead segment 4 bears tightly against the rim.

[0025] The pneumatic tire 1 surrounds, by its various sections 2-4, a generally annular or torus-shaped inner chamber 5, which extends in the circumferential direction of the pneumatic tire 1. When the assembled pneumatic tire 1 rotates and impacts on the pneumatic tire due to road unevenness, it may be excited to form resonant sound waves in the inner cavity 5, and they propagate along the circumferential direction and the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com