Oil bath built-in type sample dyeing Machine

A sample dyeing machine, oil bath type technology, applied in the field of sample dyeing machine, can solve the problems of oil fume volatilization, high cost of glycerin, large power consumption, etc., and achieve the effects of energy saving, high production efficiency and small heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

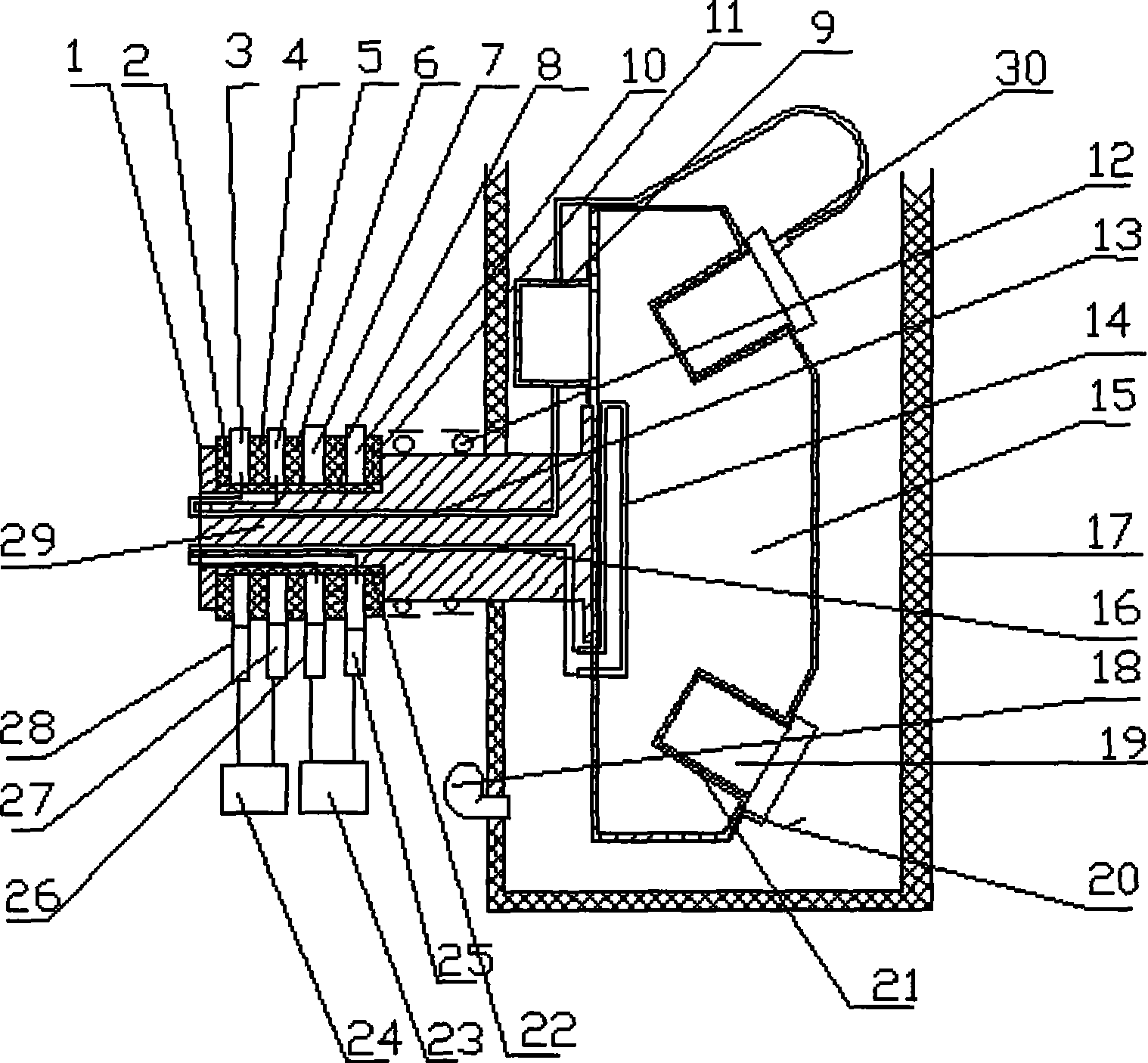

[0011] A kind of built-in oil bath type dyeing machine provided by the present invention is characterized in that: it comprises a closed oil cylinder, inside the oil cylinder is heating oil 15, and a plurality of dyeing cup heating seats 21 can be arranged on the oil cylinder, inside the dyeing cup heating seats 21 Place the dyeing cup and the dyeing cup fixing device, wherein a temperature sensor 30 is arranged in one of the dyeing cups, the oil cylinder is connected with the rotating main shaft 29, and the first copper ring 3 and the second copper ring 5, which are insulated from the main shaft, are arranged on the main shaft. The first heating slip ring 7 and the second heating slip ring 10, the first signal carbon brush 28, the second signal carbon brush 27, the heating line carbon brush 26, the heating zero line carbon brush 25 are respectively connected with the first copper ring 3, The second copper ring 5, the first heating collector ring 7 and the second heating collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com