Radiator

A heat sink and heat dissipation fin technology, which is applied in the direction of electrical solid devices, semiconductor devices, cooling/ventilation/heating transformation, etc., can solve the problems of complex structure, inconvenient assembly, easy existence of air gaps, etc., and achieve high heat transfer speed, Large thermal contact area and improved heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further description will be made below in conjunction with the embodiments with reference to the accompanying drawings.

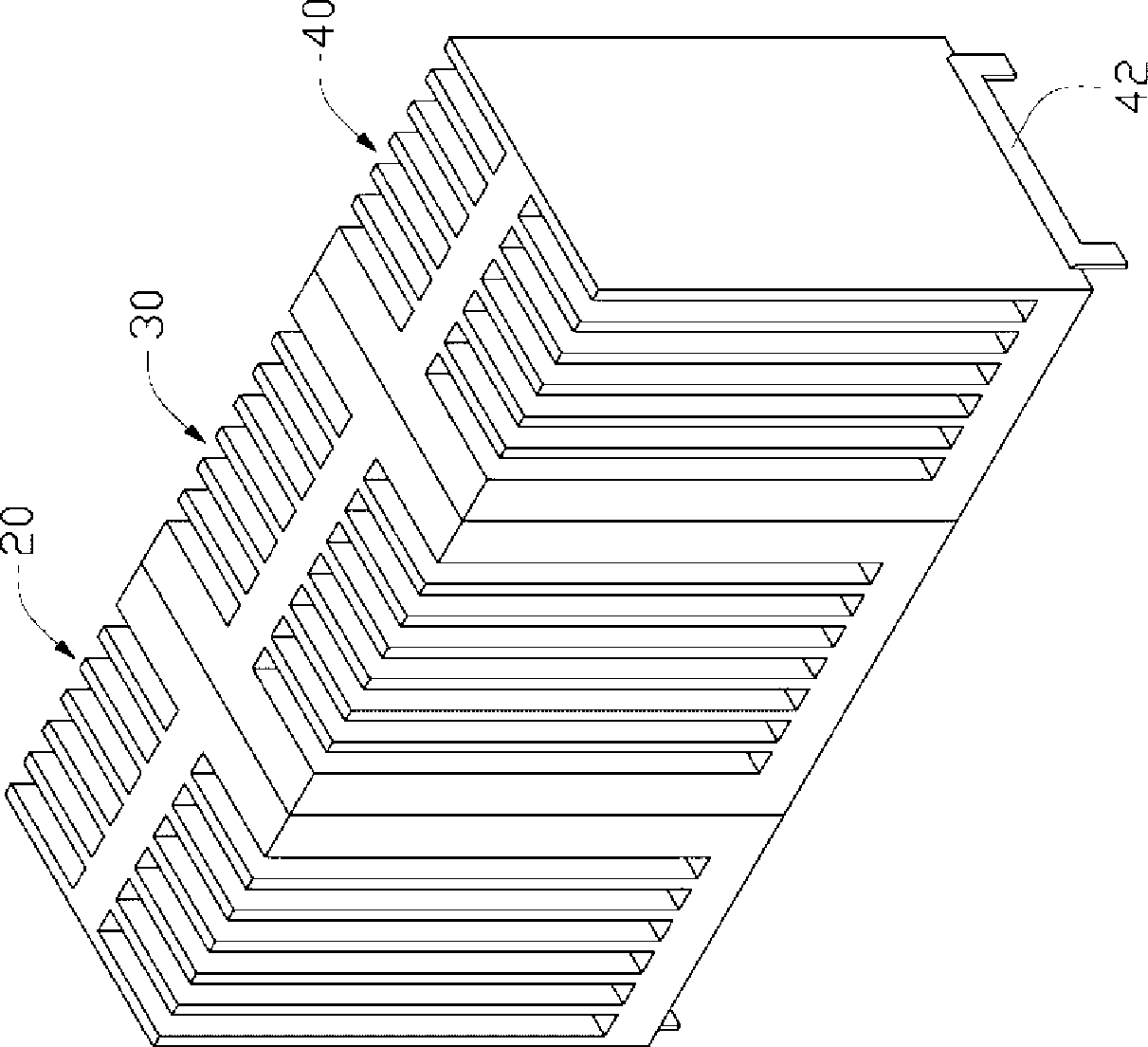

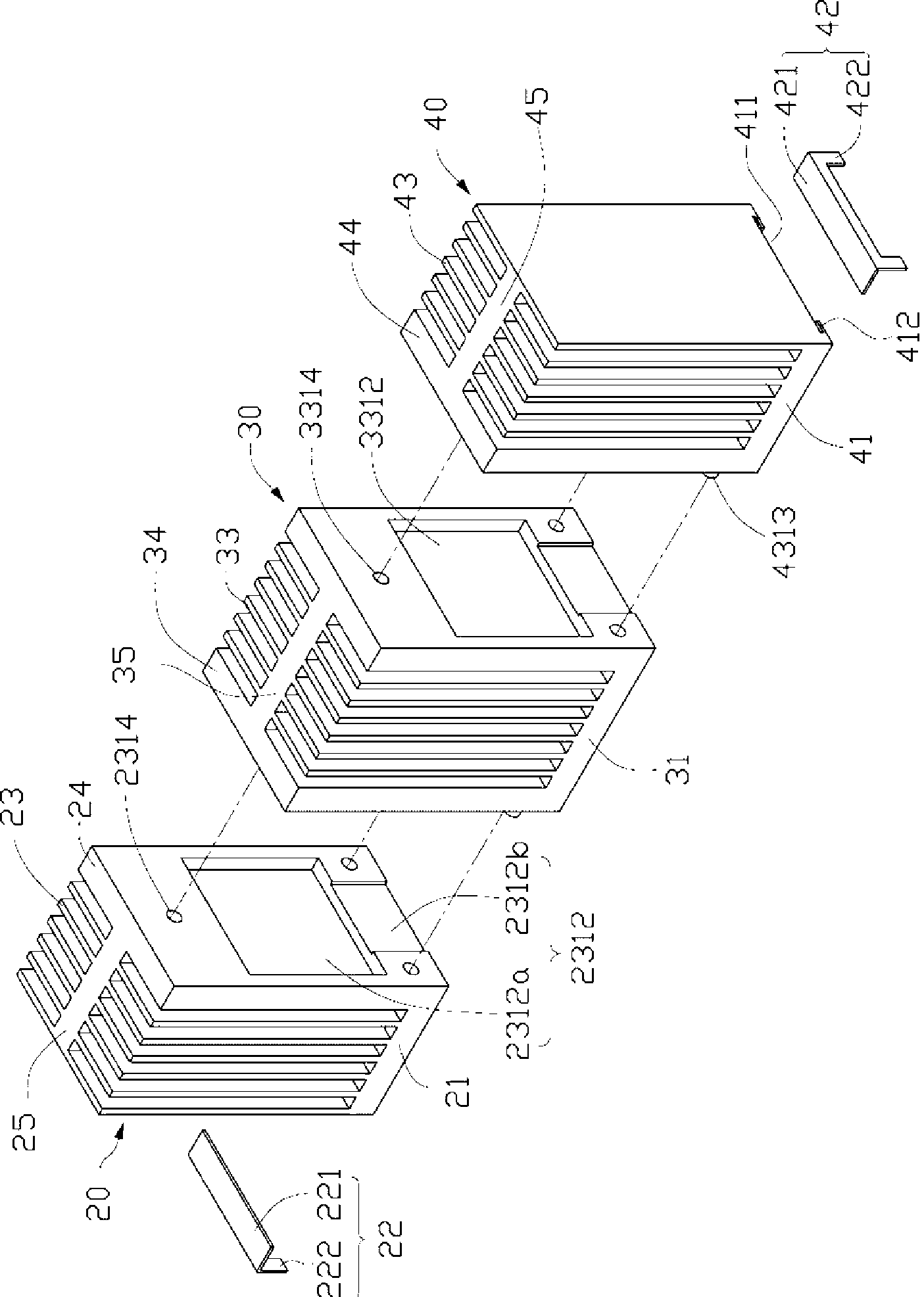

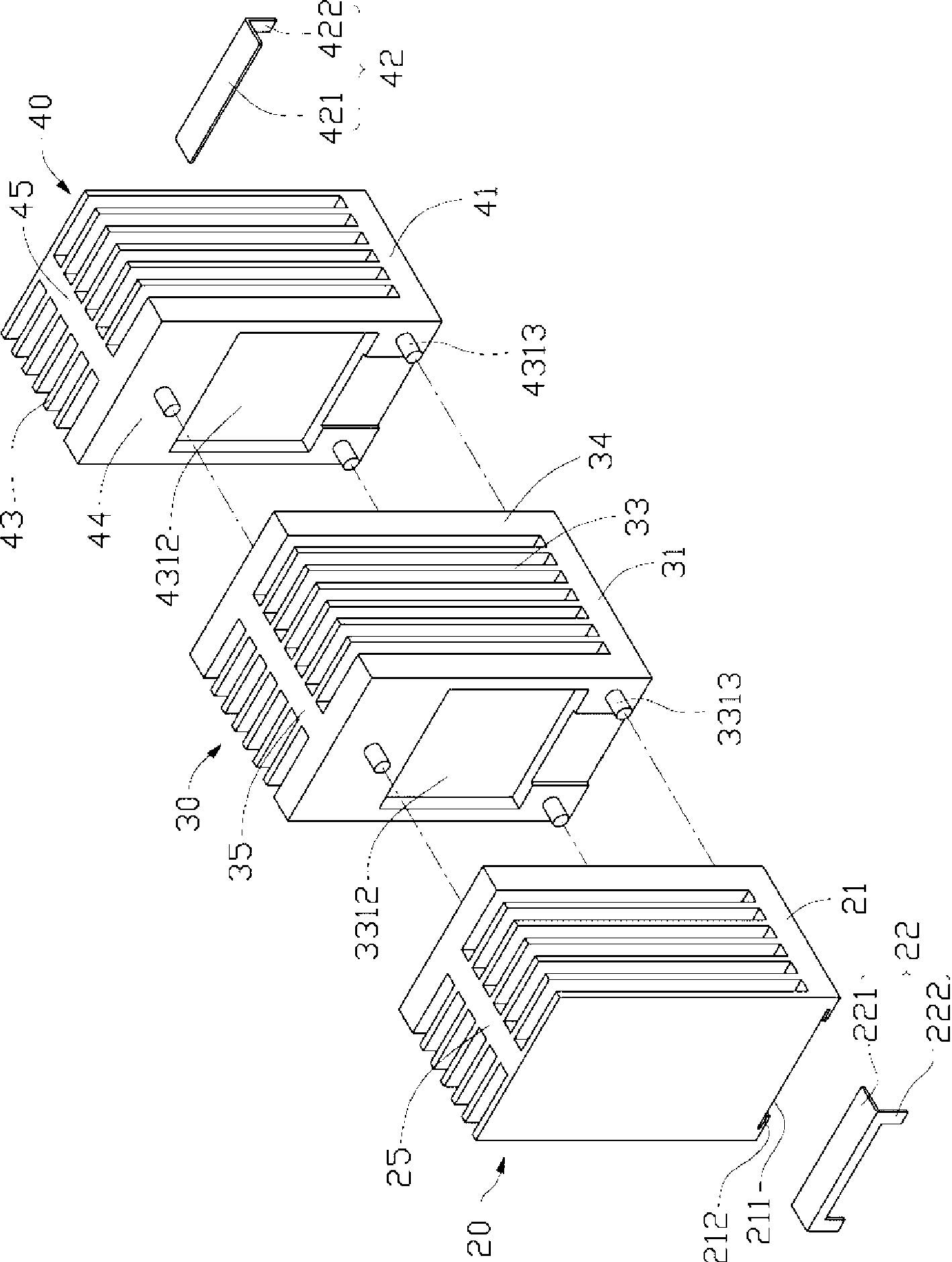

[0014] Such as figure 1 As shown, it is the first embodiment of the present invention. The radiator includes a first heat dissipation fin group 20, a second heat dissipation fin group 40 and a A third cooling fin group 30 between them.

[0015] Please also refer to figure 2 and image 3 The first heat dissipation fin group 20 includes a flat base 21, a fixing frame 22 arranged under the base 21, a plurality of heat dissipation fins 23 extending upward from the base 21, and a plurality of heat dissipation fins 23 extending upward from the edge of the base 21. The side plate 24 and a heat dissipation wall 25 connected between the plurality of heat dissipation fins 23 . The base 21 has opposite upper and lower surfaces, and the plurality of cooling fins 23 vertically extend upward from the upper surface of the base 21 and are arranged parallel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com