Centring type rotary plunger oil-well pump

A technology of oil well pump and rotary column, which is applied in the field of centering rotary plunger oil well pump, can solve the problems of oil production accident shutdown loss, low actual benefit of oil field, little improvement of pump barrel friction, etc., and achieve reduction of oil production cost, The effect of lightening the load and reducing the number of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

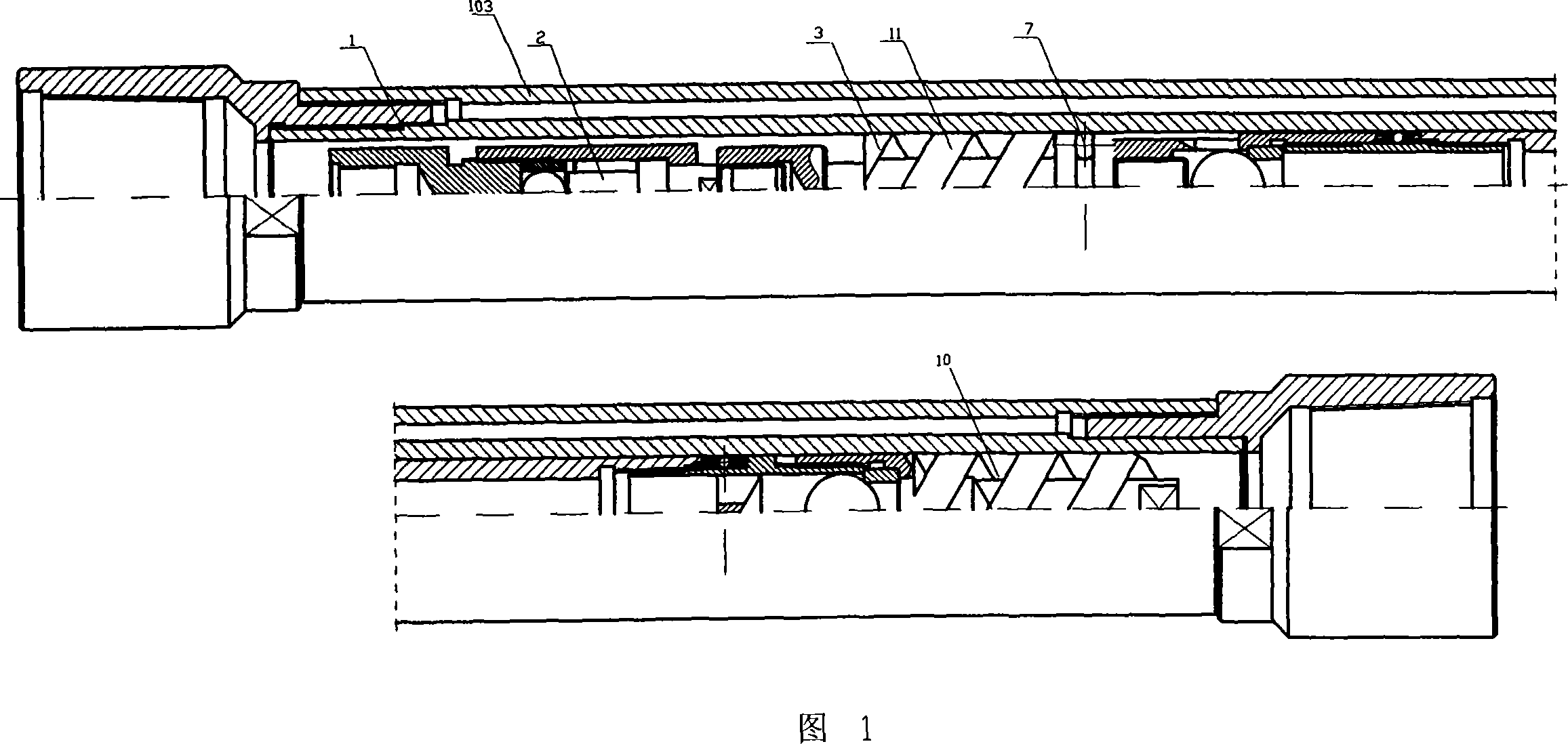

[0033] like figure 1 As shown, the overall structure of the centering rotary plunger oil pump of the present invention includes three parts: a pump barrel unit, a plunger unit, and a spinner unit.

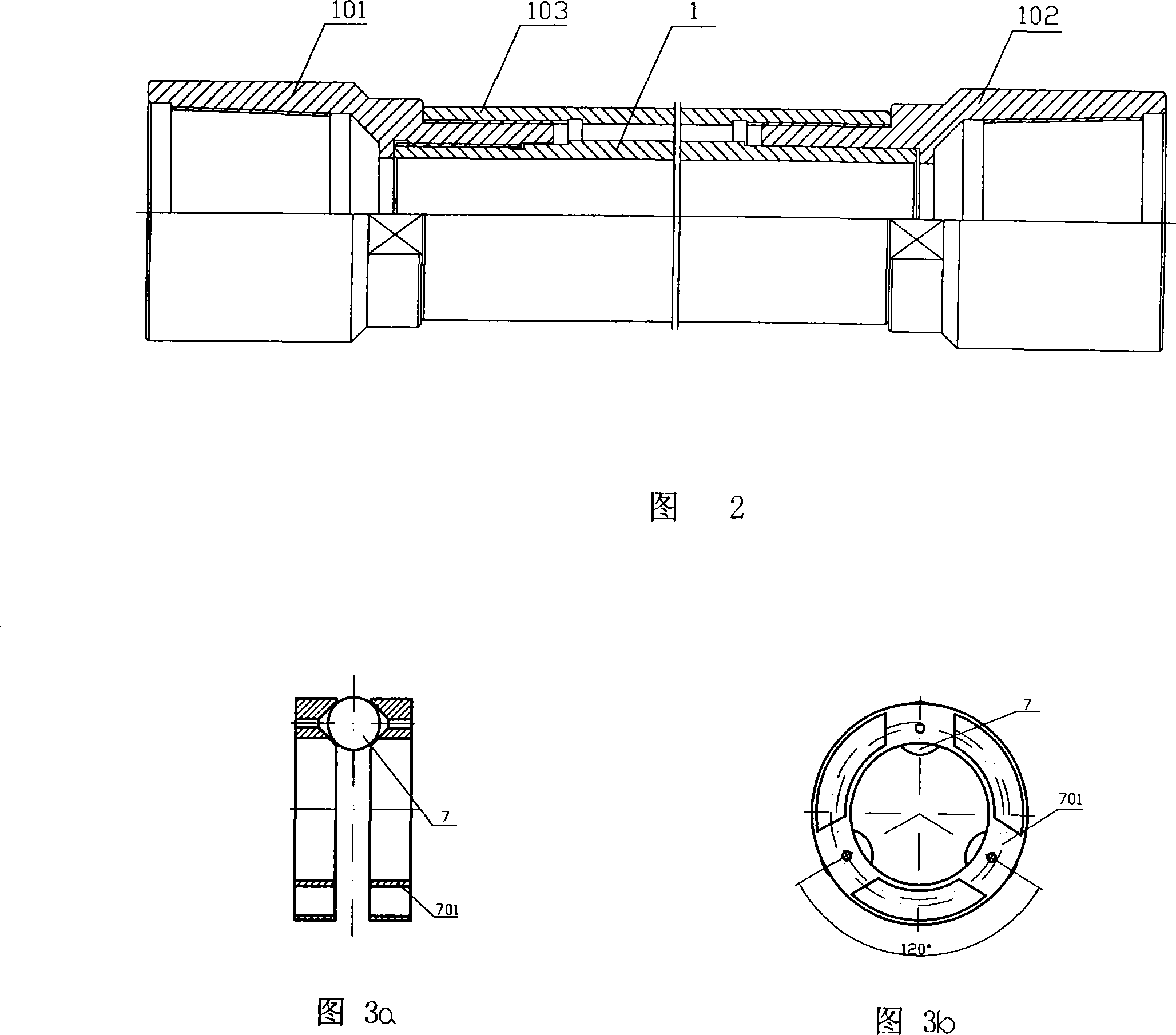

[0034] like figure 2 As shown, the two ends of the pump barrel 1 are provided with upper and lower couplings 101 and 102. The improvement of the present invention to the pump barrel unit is: a strengthening pipe 103 is sleeved on the periphery of the pump barrel, and the two ends of the strengthening pipe are respectively connected to the upper and lower pipes. The lower couplings 101 and 102 are screwed together, so that the pump barrel forms a double-tube structure, and the strength is greatly enhanced.

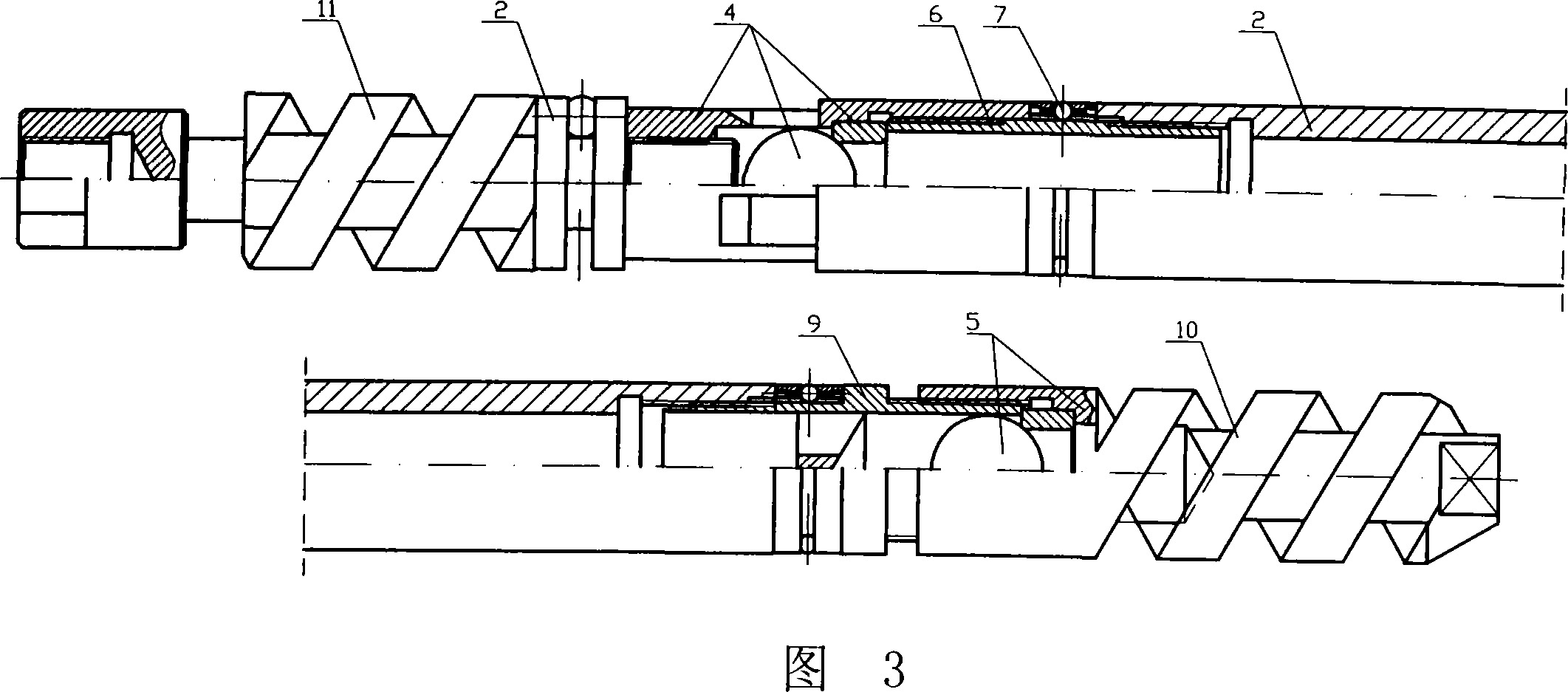

[0035] like image 3 As shown in the figure, the plunger unit 3 is the core transformation unit of the present invention. Similar to the prior art, the upper and lower joints 6 and 9 of the plunger are respectively connected to the inlet and outlet valves 4 and 5. The ends h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com