Oral solid preparation of Febuxostat with high-bioavailability and preparation method thereof

A solid preparation, the technology of febuxostat, which is applied to mixed crystal form and amorphous micronized tablet and its preparation, and the field of single crystal form of febuxostat, can solve the problem of insufficient guarantee to prepare bioavailability and high preparation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

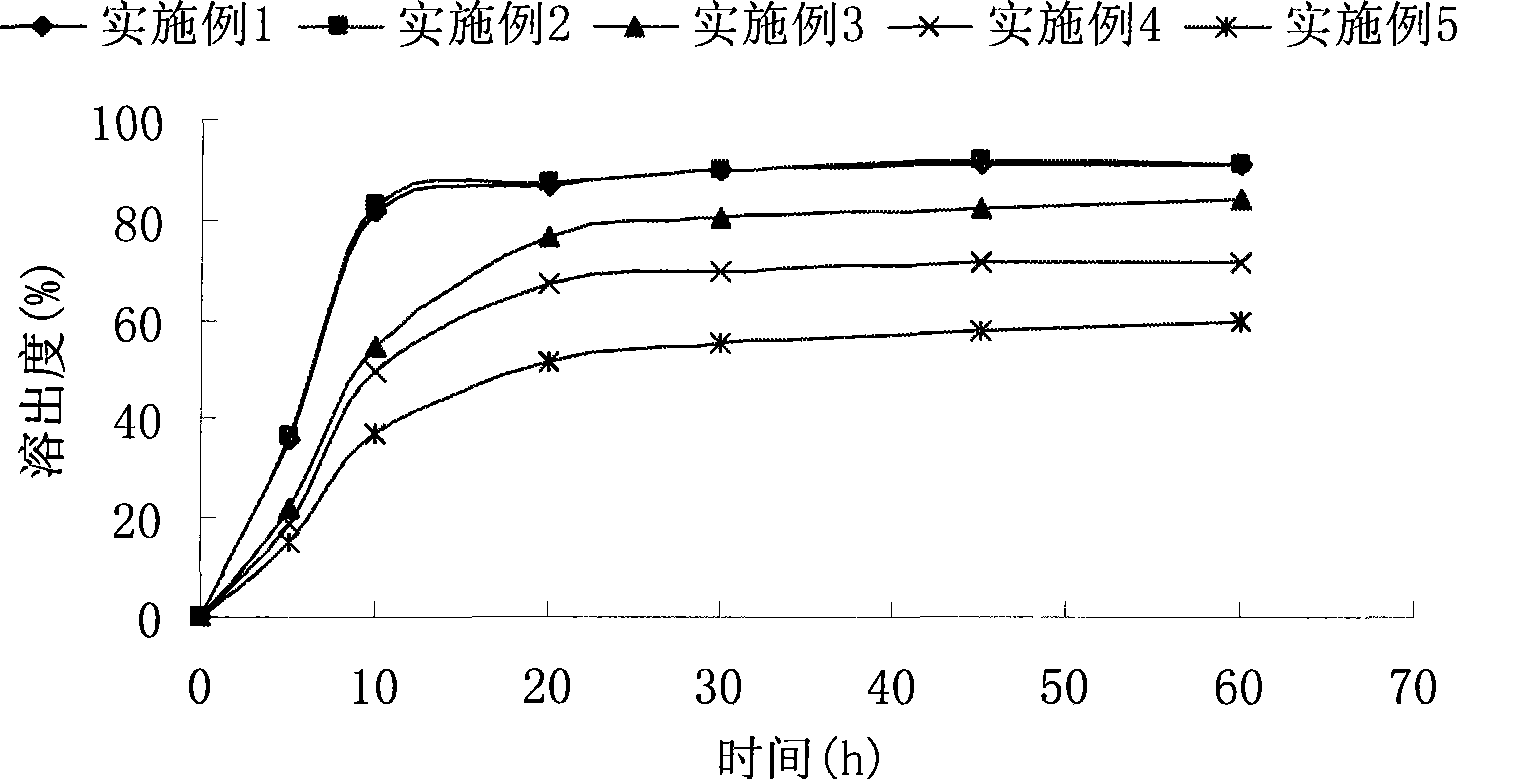

Embodiment 1

[0053] prescription:

[0054] Febuxostat (H crystal form) 120mg

[0055] Lactose 240mg

[0056] Microcrystalline Cellulose 60mg

[0057] Croscarmellose Sodium 15mg

[0058] Magnesium Stearate 4.5mg

[0059] 1% hypromellose aqueous solution appropriate amount

[0060] Preparation Process:

[0061] 1. Treat the febuxostat raw material to an average particle size range of 1-3.5 μm, and set aside;

[0062] 2. Pass lactose, microcrystalline cellulose, croscarmellose sodium and magnesium stearate through 80-mesh sieve for later use;

[0063] 3. Prepare hypromellose with purified water to a concentration of 1% for later use;

[0064] 4. Mix febuxostat, lactose, microcrystalline cellulose and croscarmellose sodium evenly, add a binder to make a soft material, sieve the soft material to obtain wet granules, and dry at 50°C to 60°C. After the dried granules are sieved and sized, magnesium stearate and croscarmellose sodium are added and mixed evenly to obtain a semi-finished pro...

Embodiment 2

[0066] prescription:

[0067] Febuxostat (H crystal form) 120mg

[0068] Lactose 240mg

[0069] Microcrystalline Cellulose 60mg

[0070] Croscarmellose Sodium 15mg

[0071] Magnesium Stearate 4.5mg

[0072] 1% hypromellose aqueous solution appropriate amount

[0073] Preparation Process:

[0074] 1. Treat the febuxostat raw material to an average particle size range of 3.5-10 μm, and set aside;

[0075] 2. Pass lactose, microcrystalline cellulose, croscarmellose sodium and magnesium stearate through 80-mesh sieve for later use;

[0076] 3. Prepare hypromellose with purified water to a concentration of 1% for later use;

[0077] 4. Mix febuxostat, lactose, microcrystalline cellulose and croscarmellose sodium evenly, add a binder to make a soft material, sieve the soft material to obtain wet granules, and dry at 50°C to 60°C. After the dried granules are sieved and sized, magnesium stearate and croscarmellose sodium are added and mixed evenly to obtain a semi-finished pr...

Embodiment 3

[0079] prescription:

[0080] Febuxostat (H crystal form) 120mg

[0081] Lactose 240mg

[0082] Microcrystalline Cellulose 60mg

[0083] Croscarmellose Sodium 15mg

[0084] Magnesium Stearate 4.5mg

[0085] 1% hypromellose aqueous solution appropriate amount

[0086] Preparation Process:

[0087] 1. Treat the febuxostat raw material to an average particle size range of 10-20 μm, and set aside;

[0088] 2. Pass lactose, microcrystalline cellulose, croscarmellose sodium and magnesium stearate through 80-mesh sieve for later use;

[0089] 3. Prepare hypromellose with purified water to a concentration of 1% for later use;

[0090] 4. Mix febuxostat, lactose, microcrystalline cellulose and croscarmellose sodium evenly, add a binder to make a soft material, sieve the soft material to obtain wet granules, and dry at 50°C to 60°C. After the dried granules are sieved and sized, magnesium stearate and croscarmellose sodium are added and mixed evenly to obtain a semi-finished pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com