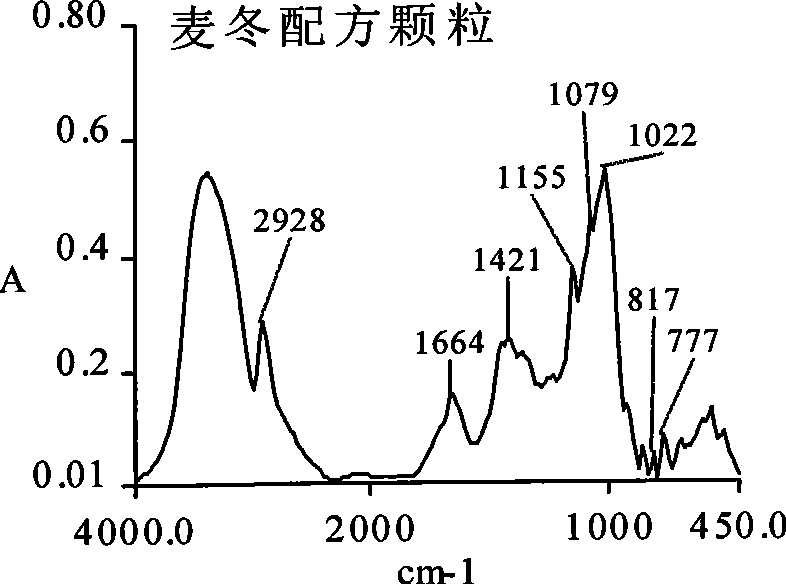

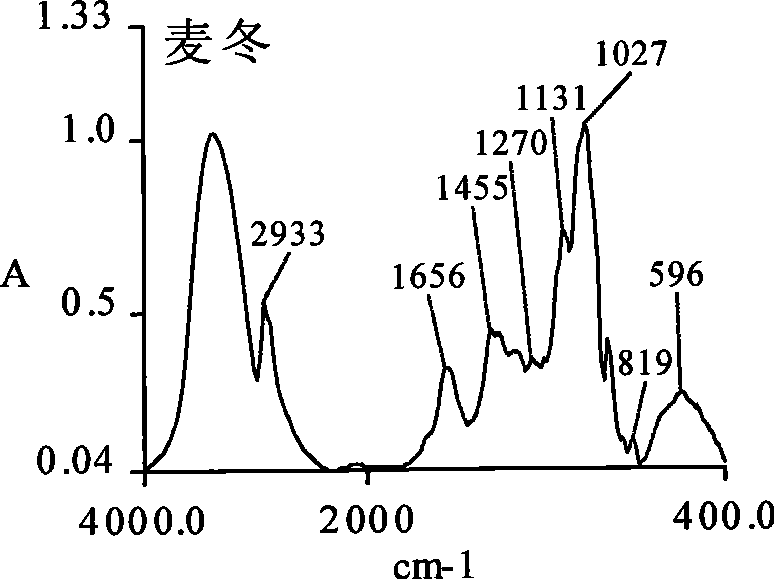

Ophiopogon root dispensing granule as well as preparation method and quality control method thereof

A technology of formula granules and Ophiopogon japonicus, which is applied in the field of traditional Chinese medicine formula granules and its preparation method and quality control, and can solve problems such as difficulties in spectrum analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Ophiopogon japonicus formula granules

[0037] Take 100kg of Ophiopogon japonicus slices, add 800kg of water, extract for 2 hours, that is, the first decoction; after the first decoction, add 800kg of water to the dregs, extract for 1.5 hours, that is, the second decoction; combine the two decoctions, concentrate under reduced pressure to a relative density of 1.05- 1.10; the concentrated solution is preheated at 45°C, the inlet air temperature is 180°C, the material pump speed is 550 rpm, the outlet air temperature is 80°C, and the air delivery temperature is 45°C, and the spray-dried powder is obtained to obtain Ophiopogon japonicus spray-dried powder; Add the auxiliary material dextrin of its own weight portion 0-5% in the spray-dried powder of winter; The spray-dried powder of Ophiopogon japonicus is 5MPa in the pressure of main pinch wheel, and the pressure of side pinch wheel is 0.5MPa, and the spindle speed is 400 rpm, and the feeding voltage Dry gr...

Embodiment 2

[0038] Embodiment 2: Ophiopogon japonicus formula granules

[0039] Take 100kg of Ophiopogon japonicus decoction pieces, add 1000kg of water, extract for 2 hours, that is, the first decoction; after the first decoction, add 600kg of water to the dregs, extract for 1 hour, that is, the second decoction; combine the two decoctions, concentrate under reduced pressure to a relative density of 1.00— 1.05; the concentrated solution is preheated at 50°C, the inlet air temperature is 170°C, the material pump speed is 600 rpm, the outlet air temperature is 75°C, and the air supply temperature is 50°C, and spray-dried to obtain Ophiopogon japonicus spray-dried powder; Add 5-15% of its own weight of auxiliary material dextrin to the winter spray-dried powder; under the conditions that the main pressure wheel pressure is 6MPa, the side pressure wheel pressure is 0.4MPa, the spindle speed is 450 rpm, and the feeding voltage is 110V Dry granulation to obtain 20-60 mesh Ophiopogon japonicus ...

Embodiment 3

[0041] Embodiment 3: Ophiopogon japonicus formula granules

[0042] Take 100kg of Ophiopogon japonicus slices, add 1400kg of water, extract for 2.5 hours, that is, the first decoction; after the first decoction, add 1100kg of water to the dregs, extract for 2.5 hours, that is, the second decoction; combine the two decoctions, concentrate under reduced pressure to a relative density of 1.10- 1.15; the concentrate is preheated at 45°C, the inlet air temperature is 170°C, the material pump speed is 600 rpm, the outlet air temperature is 75°C, and the air supply temperature is 50°C, and the spray-dried powder is obtained to obtain Ophiopogon japonicus spray-dried powder; Add 15-25% of its own weight of lactose to the winter spray-dried powder; dry process under the conditions that the pressure of the main roller is 4MPa, the pressure of the side roller is 0.4MPa, the speed of the main shaft is 500 rpm, and the feeding voltage is 130V. granules, to obtain 20-60 mesh Ophiopogon japo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com