Filter element

A technology of filter element and receiving part, which is applied in the direction of filtration separation, engine element, separation method, etc., can solve the problem of expensive modification of electric heater, etc., and achieve the effect of cheap heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

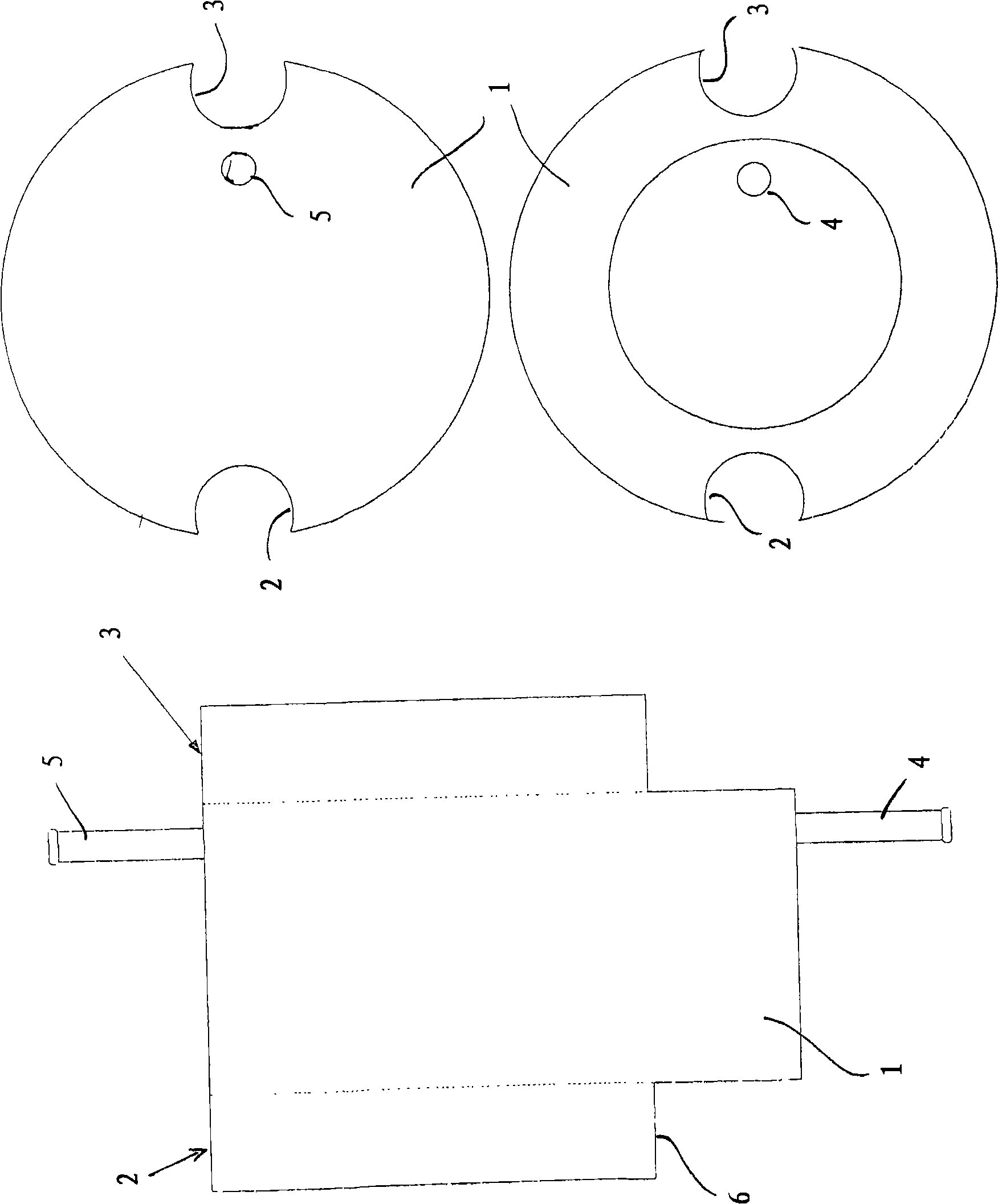

[0029] The filter element 1 has two grooves 2 and 3 on the outer side along its longitudinal extension, ie in a direction parallel to the central axis. The coolant hoses of the internal combustion engine can be inserted or snapped into the grooves 2 and 3 of the filter element 1 .

[0030] The filter element 1 is heated by means of the coolant hoses, not shown, snapped into the grooves 2 and 3 and prevents the liquid to be filtered from freezing.

[0031] The filter element 1 has two pipe connections 4 and 5 which serve as inflow and outflow for the liquid to be filtered.

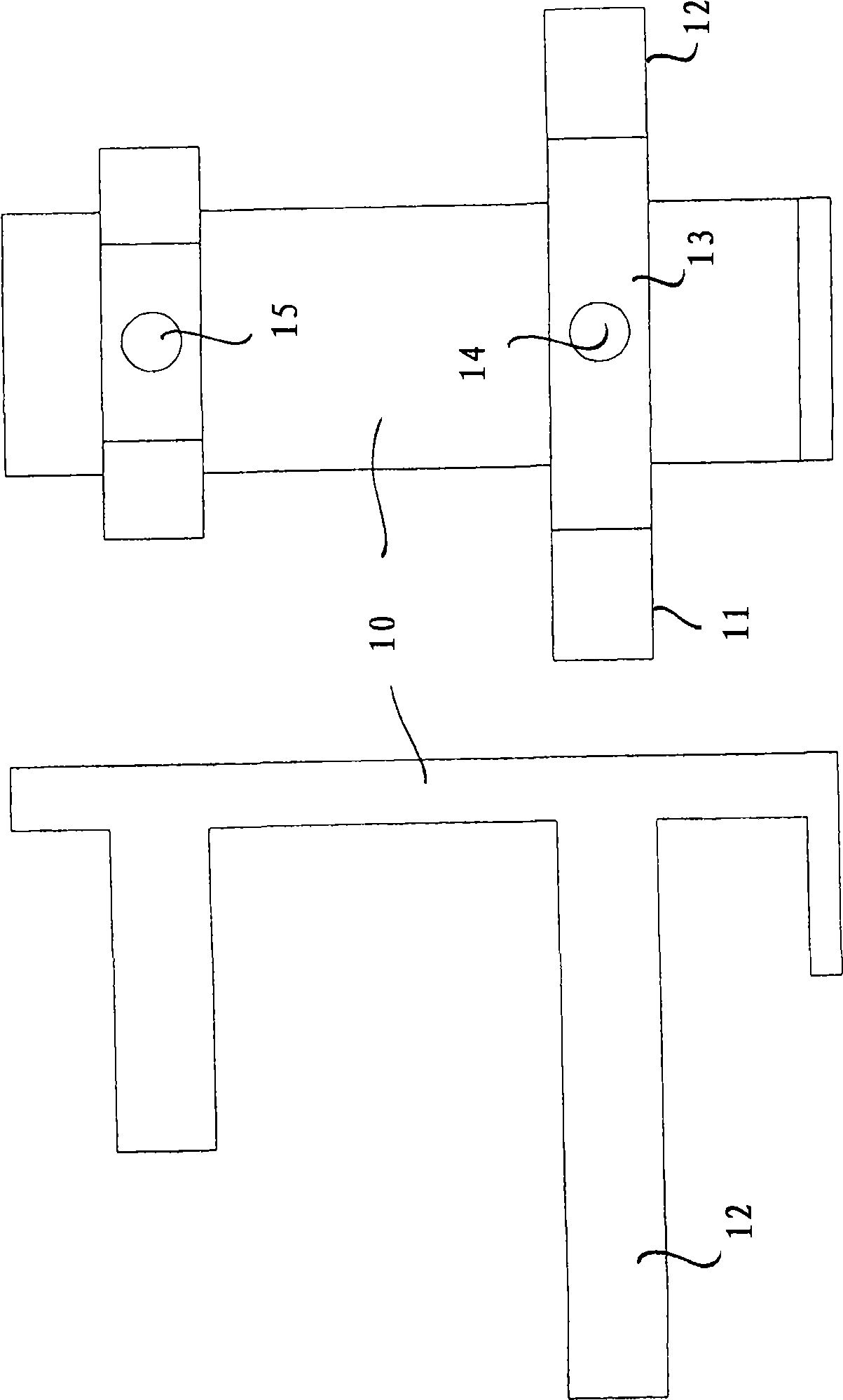

[0032] The filter element 1 is designed asymmetrically and has a shoulder 6, so that the filter element 1 can only be mounted in a unique position figure 2 corresponding bracket 10. according to figure 2 The support 10 has two projections 11 and 12 in the lower part for this purpose.

[0033] Between the two projections 11 and 12 on which the shoulder 6 of the filter element 1 rests, the support has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com