Air cooling stacking method of hot rolling steel rail

A rail and stacking technology is applied in the field of air-cooled stacking of hot-rolled rails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

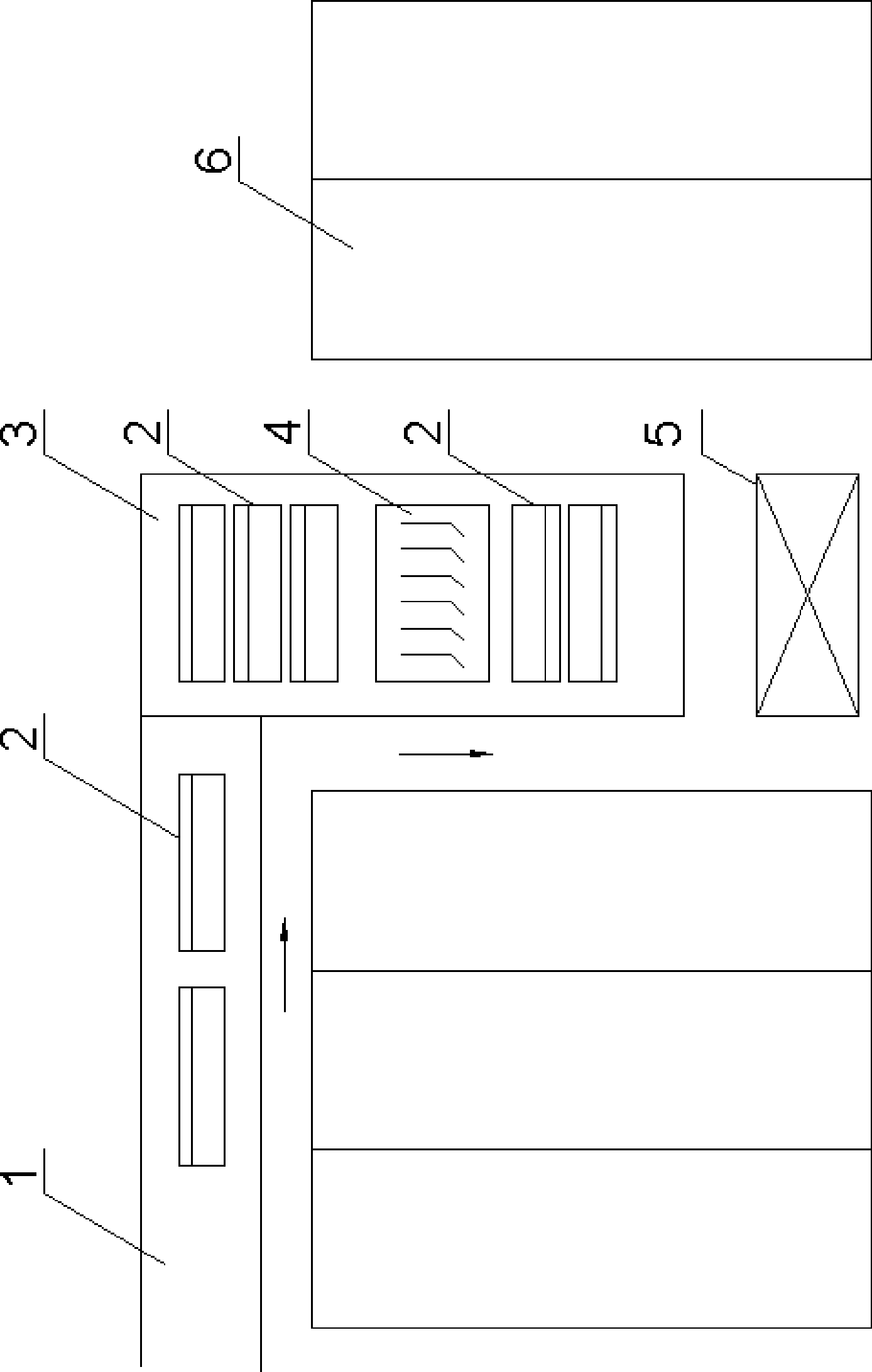

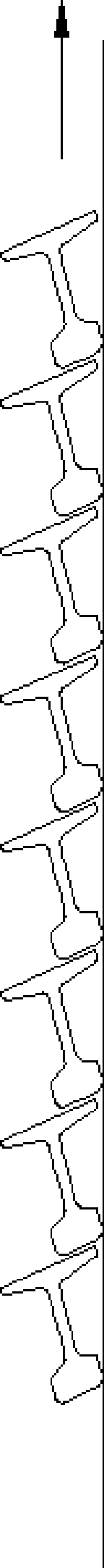

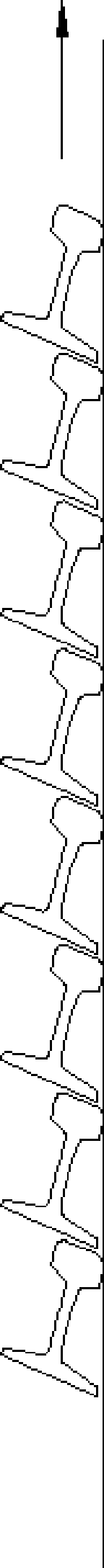

[0024] When the steel rail 2 is cooled to 600℃~700℃ on the collecting platform 3, it is turned over 180° by the steel turning machine 4, so that when the two sides of the steel rail 2 drop to about 300℃~400℃, the two The cooling rate on the side is basically the same. The overturned rail 2 is cooled to 300°C to 400°C on the collecting platform, and then the rail 2 is transported to the stacking position for stacking air cooling. When the rail 2 is at 300°C to 400°C, it is suitable for lifting by the magnetic crane 5, and the rail 2 is stacked and air-cooled at 300°C to 400°C. After complete cooling, the thermal deformation stress on both sides of the rail 2 is basically Unanimous. When stacking the rails 2, spacers are arranged between the adjacent upper rails and the lower rails, so as to separate the rail layers from each other, which is convenient for crane lifting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com