Ultra-hydrophobic film of thermoplastic substrate

A thermoplastic film and super-hydrophobic technology, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc. High structural cost and other issues, to achieve the effect of easy promotion, simple structure and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

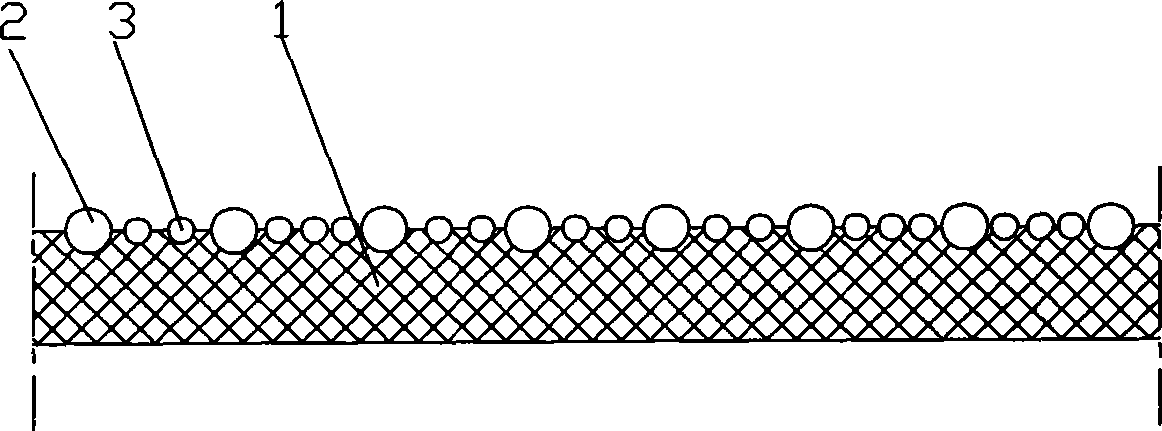

Embodiment 1

[0021] The superhydrophobic film of the thermoplastic matrix of this embodiment includes a thermoplastic film matrix 1 and a superhydrophobic layer. The material of the thermoplastic film matrix 1 is a polymer, which is easy to obtain and low in cost. In this embodiment, the polymer is polyethylene. Physical properties It is soft and adaptable, and can be applied to various surfaces; the superhydrophobic layer is composed of micron-sized particles 2 and nano-sized particles 3 that are arranged alternately and embedded in the film matrix. Micron-sized particles 2 and nano-sized particles 3 are in thermoplastic Micron-scale protrusions and nano-scale protrusions are formed on the surface of the film substrate 1; micron-scale powder particles 2 and nano-scale powder particles 3 have low surface energy; in this embodiment, micron-scale powder particles 2 and nano-scale powder particles with low surface energy Particle 3 is polytetrafluoroethylene micropowder;

[0022] The particle...

Embodiment 2

[0025] The superhydrophobic film of the thermoplastic matrix of this embodiment comprises a thermoplastic film matrix 1 and a superhydrophobic layer. The material of the thermoplastic film matrix 1 is a polymer, which is easy to obtain and low in cost. In this embodiment, the polymer is polyvinyl chloride. Soft in nature and strong in adaptability, it can be applied to various surfaces, and can also be made into a tape structure, which is convenient to use; the superhydrophobic layer is composed of micron-sized powder particles 2 and nano-sized powder particles 3 that are arranged alternately and embedded in the film matrix. The powder 2 and the nano-scale powder 3 form micron-scale protrusions and nano-scale protrusions on the surface of the thermoplastic film substrate 1; the micro-scale powder 2 and the nano-scale powder 3 are modified by low surface energy substances. Among them, the micron-sized particles 2 and nano-sized particles 3 modified by low surface energy substanc...

Embodiment 3

[0029] The superhydrophobic film of the thermoplastic matrix of this embodiment includes a thermoplastic film matrix 1 and a superhydrophobic layer. The material of the thermoplastic film matrix 1 is a polymer, which is easy to obtain and low in cost. In this embodiment, the polymer is polypropylene, and the physical properties It is soft and adaptable, and can be applied to various surfaces; the superhydrophobic layer is composed of micron-sized particles 2 and nano-sized particles 3 that are arranged alternately and embedded in the film matrix. Micron-sized particles 2 and nano-sized particles 3 are in thermoplastic Micron-scale protrusions and nano-scale protrusions are formed on the surface of the film substrate 1; micron-scale powder particles 2 and nano-scale powder particles 3 have low surface energy; in this embodiment, micron-scale powder particles 2 and nano-scale powder particles with low surface energy Particle 3 is perfluoroethylene propylene micropowder;

[0030]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com