Automatic stamping machine and stamping method thereof

A technology of automatic stamping machine and transmission mechanism, which is applied in the field of stamping machine, can solve the problems of wasting time and energy, uneconomical cost performance, high equipment price, etc., and achieves easy disassembly and maintenance, clear imprint, and adjustable working frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

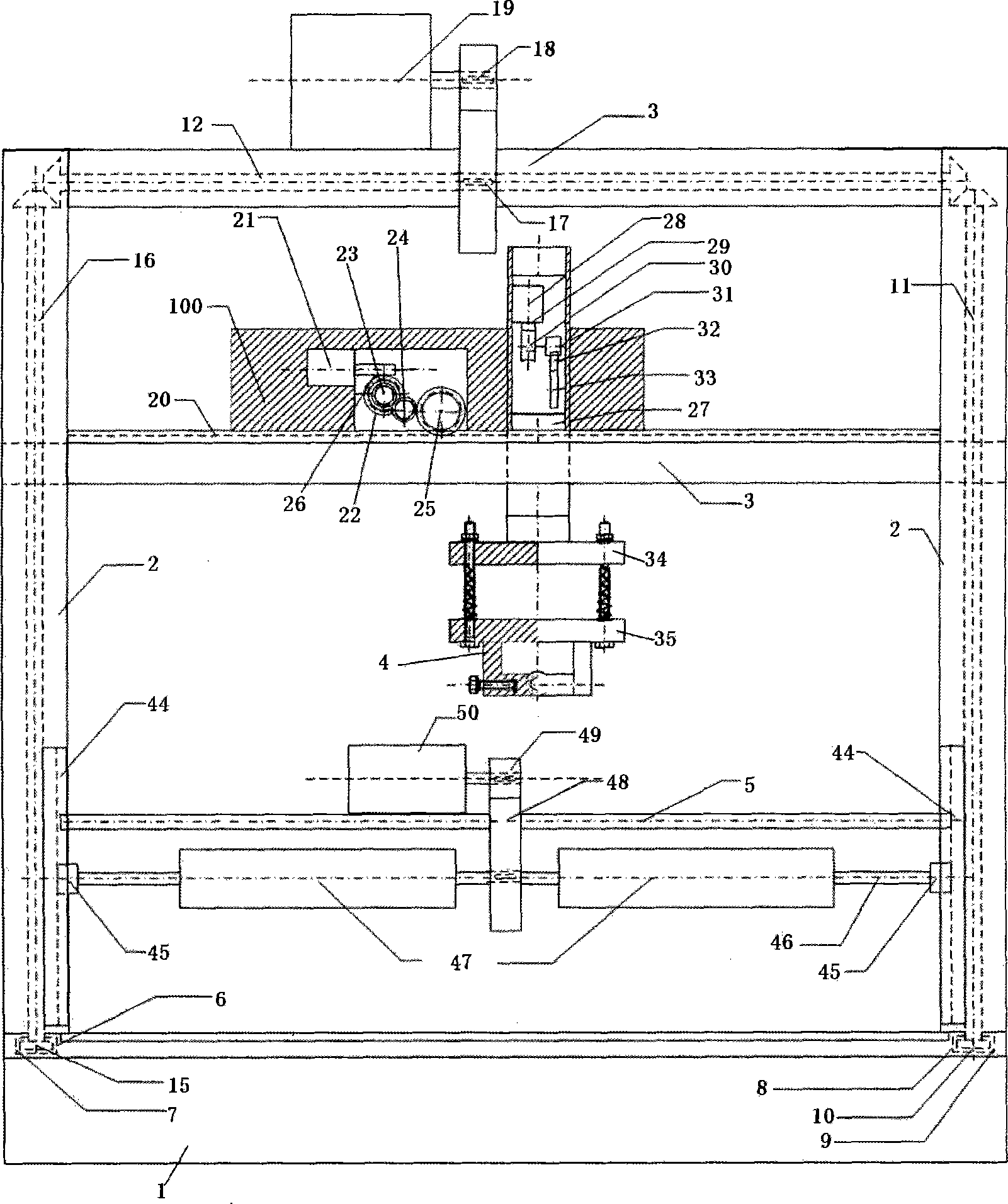

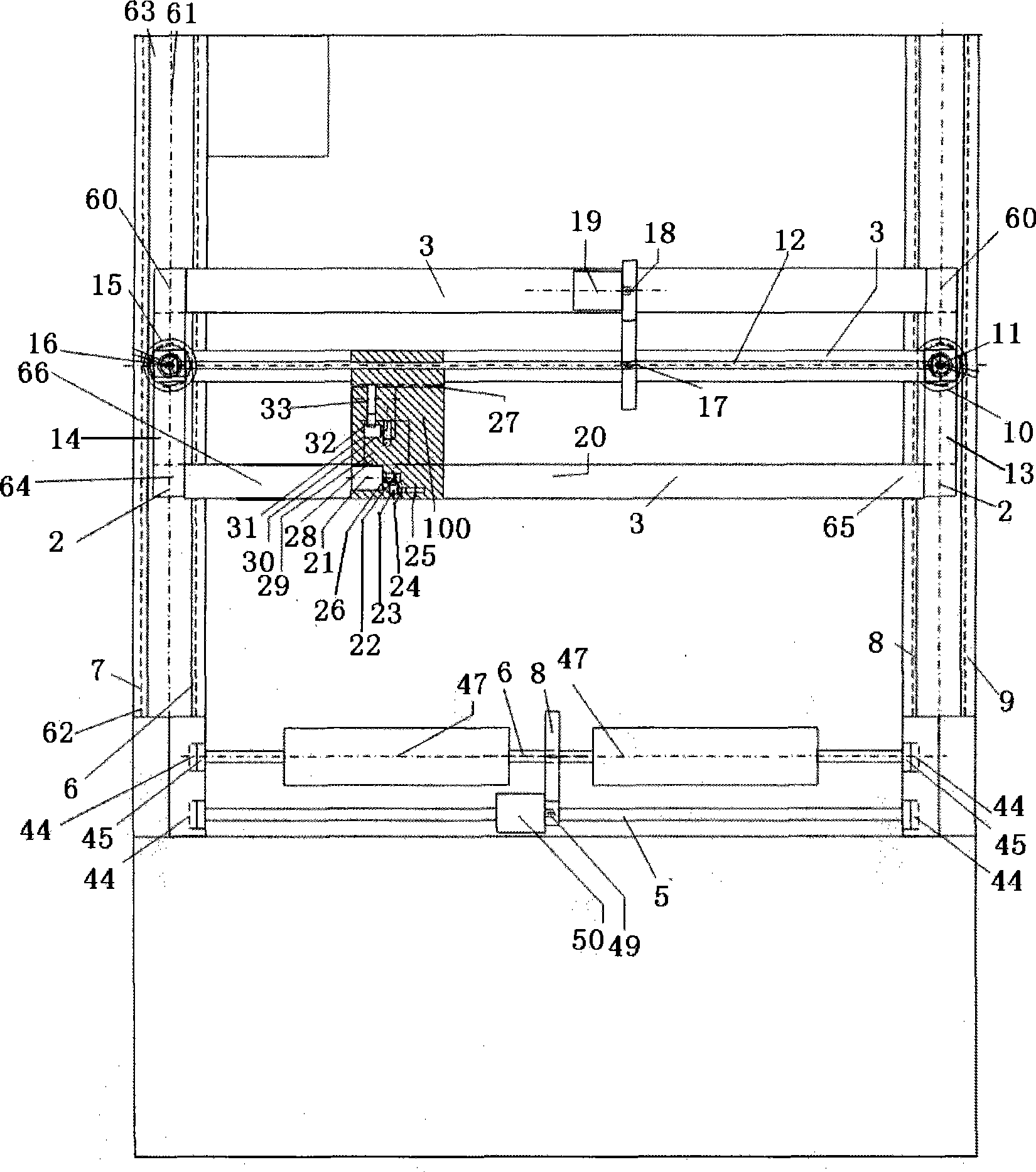

[0030] Such as figure 1 , shown in 2, the automatic stamping machine of the present invention is made up of two major parts of machinery and electricity, and mechanical part comprises base 1, vertical movement mechanism, lateral movement mechanism, hammering mechanism, paper transmission mechanism, stamp fixture 4; Electric part Including programmable logic controller PLC, limit sensor, start, stop button switch, motor, toggle switch, photoelectric sensor.

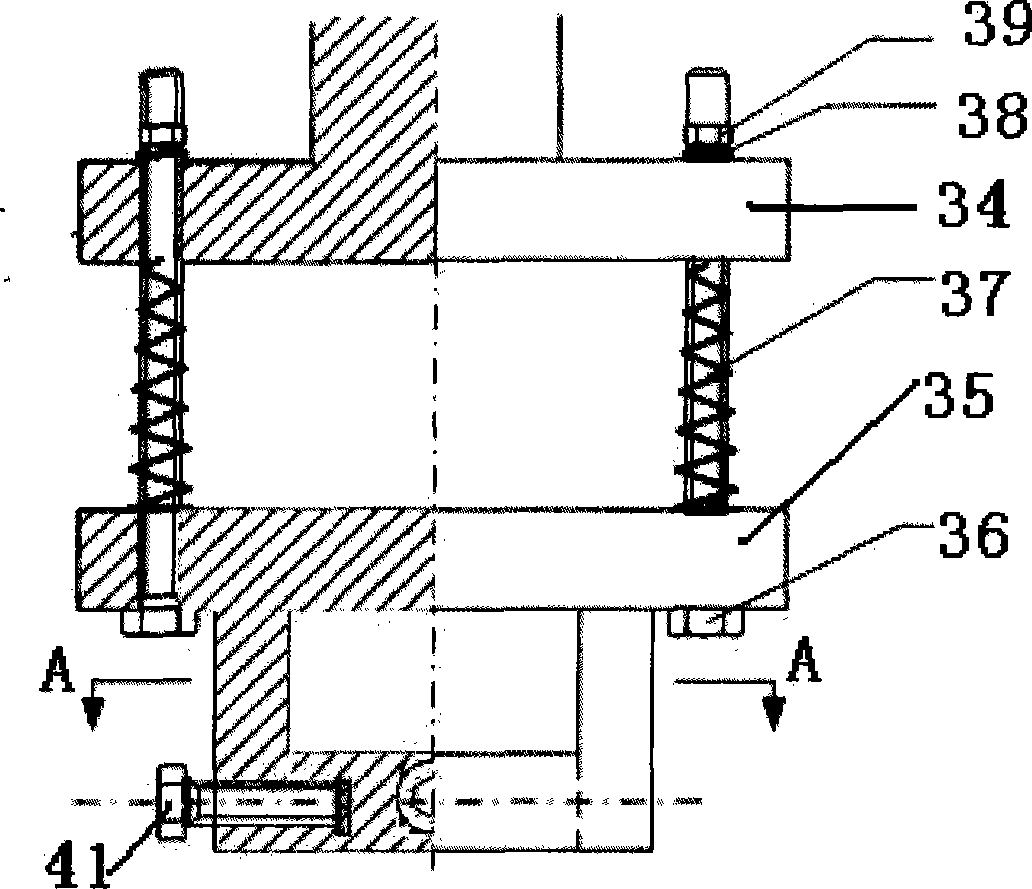

[0031] Both sides of the base 1 are equipped with vertical fixed brackets 2 respectively, and a longitudinal moving mechanism is installed between the two vertical fixed brackets 2; the base 1 is equipped with horizontal fixed brackets 3 respectively, and a horizontal moving mechanism is installed between the two horizontal fixed brackets 3 The knocking transmission mechanism of the stamping mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com