Acrylic amide modified polymer micro-crosslinking gel and preparation thereof

A technology of micro-crosslinked gel and acrylamide, which is applied in the fields of polymer materials and oil field chemistry, and can solve problems such as poor anti-aging stability, poor temperature resistance, and short validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

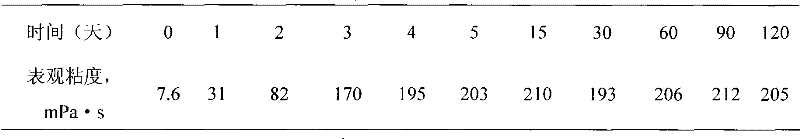

Embodiment 1

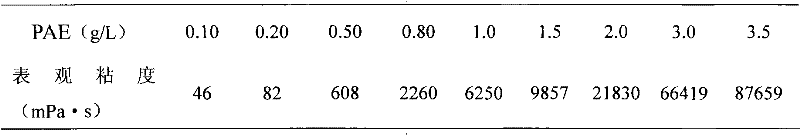

[0028] Dissolve 20.000 grams of acrylamide, 8.042 grams of acrylic acid, and 1.800 grams of 4-vinylbenzyloctylphenol polyoxyethylene ether (the adduct EO of polyoxyethylene ether is 40) in 380 mL of distilled water, add them to a three-necked reaction flask, and use NaOH adjusts the pH of the solution to 8, the reaction temperature is 65°C, and N 2 After 30 minutes, add 6.50 mL of 0.05 mol / L potassium persulfate initiator solution, react for 32 hours, and dilute the polymer with water to obtain a concentrated PAE solution. Take a certain amount of polymer PAE to prepare an oil displacement agent aqueous solution sample, and the sample is colorless and transparent. Add an aqueous solution with a polymer concentration of 0.5g / L, an aluminum citrate concentration of 0.15g / L, a sodium dodecylbenzenesulfonate concentration of 0.3mmol / L, and a sodium sulfite concentration of 0.03g / L, and add a stirring device In a mixing container, stir evenly at room temperature, adjust the pH of ...

Embodiment 2

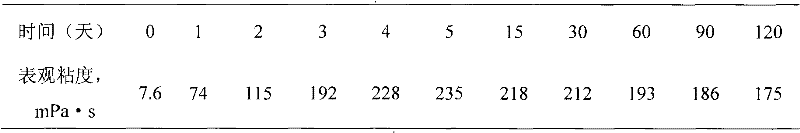

[0030] 20.000 grams of acrylamide, 6.300 grams of 2-acrylamido-2-methylpropanesulfonic acid, 9.500 grams of 4-vinylbenzyl octylphenol polyoxyethylene ether (the adduct EO of polyoxyethylene ether is 20) Dissolve in 120mL distilled water, add to a three-necked reaction flask, adjust the pH of the solution to 7 with NaOH, the reaction temperature is 60°C, and pass through N 2 After 30 minutes, add 5.20 mL of 0.05 mol / L potassium persulfate initiator solution, react for 32 hours, and dilute the polymer with water to obtain a concentrated PAE solution. Take a certain amount of polymer PAE to prepare an oil displacement agent aqueous solution sample, and the sample is colorless and transparent. The concentration of the polymer is 2.2g / L, the concentration of oligophenolic resin is 0.75g / L, the concentration of sodium dodecylbenzenesulfonate is 0.2mmol / L, and the concentration of sodium sulfite is 0.05g / L. In the mixing container of the device, stir evenly at room temperature, adju...

Embodiment 3

[0032] 20.000 grams of acrylamide, 5.100 grams of 3-acrylimido-3-methylbutanoic acid, and 7.000 grams of allyl octylphenol polyoxyethylene ether (the adduct EO of polyoxyethylene ether is 12) were dissolved in Add 630mL of distilled water into a three-necked reaction flask, adjust the pH of the solution to 5 with NaOH, the reaction temperature is 60°C, and pass through N 2 After 30 minutes, add 12.0 mL of 0.05 mol / L potassium persulfate initiator solution, react for 24 hours, and dilute the polymer with water to obtain a concentrated PAE solution. Take a certain amount of polymer PAE to prepare an oil displacement agent aqueous solution sample, and the sample is colorless and transparent. The polymer concentration is 1.2g / L, the total concentration of phenol and glutaraldehyde is 0.25g / L, the concentration of sodium dodecylbenzenesulfonate is 0.2mmol / L, and the aqueous solution of sodium sulfite concentration is 0.03g / L, add Stir evenly at room temperature in a mixing vessel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com