Atmospheric vacuum distillation process for light crude oil

A technology of atmospheric and vacuum distillation and light crude oil, applied in hydrocarbon distillation, petroleum industry, vacuum distillation, etc., can solve the problems of ineffective fractionation of light crude oil, meet the requirements of long-term operation and save investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

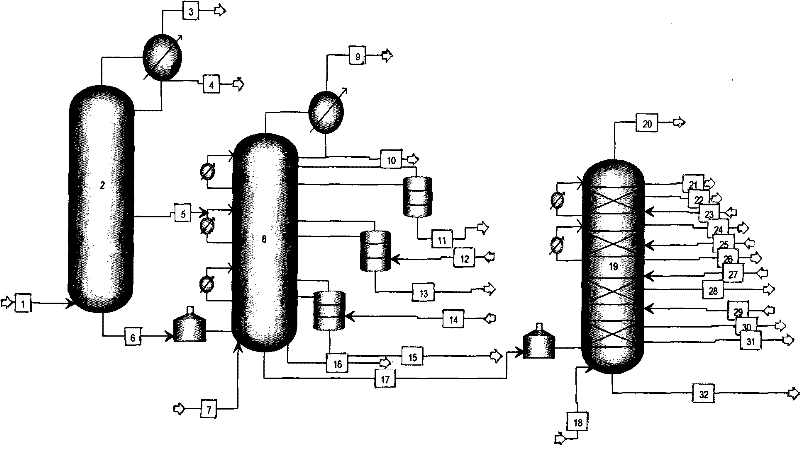

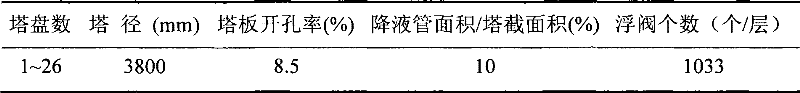

[0023] Oman, Saudi Arabia, and Iran are 1:1:1 (mass ratio). The blended crude oil has an API degree of 32.8, a distillate yield of 54.2% before 360°C, and a higher fraction content of the mixed crude oil at 200-400°C. The mixed crude oil is treated with secondary desalting. Such as figure 1 As shown, the mixed crude oil 1 after secondary desalination enters the primary distillation tower 2 after heat exchange. The specification of the initial distillation column is φ3800×12 / 14×40472. The plate spacing is 0.6m, and the technical specifications of the trays are shown in Table 1. The operating conditions of the initial distillation tower are shown in Table 2. The pressure at the top of the primary distillation tower is 0.225MPa, and the temperature of the top condenser is 60°C. The overhead reflux device extracts the initial distillation overhead water 3 and the initial distillation overhead product 4 . The distillate from the side line 5 of the primary distillation column ...

Embodiment 2

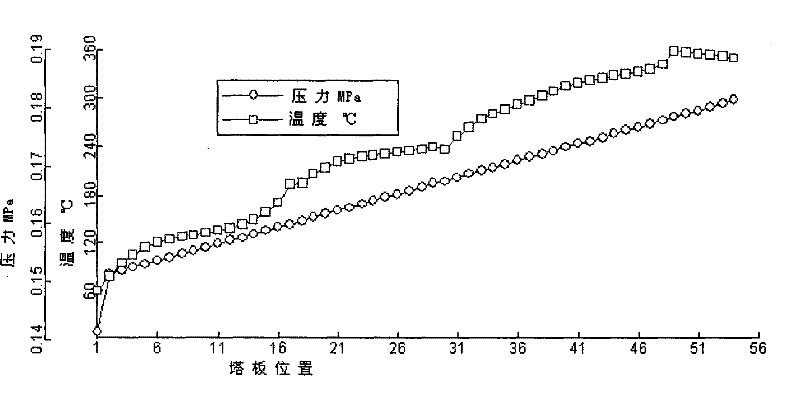

[0044] During the initial distillation process, the feed temperature of the initial distillation tower was controlled at 235°C. The pressure at the top of the primary distillation tower is 0.229MPa, and the temperature of the discharge at the top of the tower is 163°C. The initial sideline temperature was 181°C. During the atmospheric distillation process, the temperature of the crude oil entering the atmospheric tower is 355°C, and the pressure at the top of the atmospheric tower is 0.12MPa. Usually the first-line reboiler load is controlled within the range of 2.1MMkal / hr. Usually the second-line stripping steam volume is controlled at 525Kg / hr. The heat extraction ratio of the atmospheric tower is the top of the tower: the top circulation: the first middle: the second middle is equal to 1: 2.5: 4.2: 5.2. During the vacuum distillation process, the pressure at the top of the vacuum tower is 55mmHg, and the plate pressure drop is 0.27KPa. Other equipment and conditions ar...

Embodiment 3

[0047] The mixed crude oil is: Oman and Saudi Arabia are mixed at a ratio of 1:3 (mass ratio), and the distillate yield before 360°C is 58%. During the initial distillation process, the feed temperature of the initial distillation tower was controlled at 247°C. The pressure at the top of the primary distillation tower is 0.227MPa, and the temperature of the discharge at the top of the tower is 160°C. The initial sideline temperature was 178°C. During the atmospheric distillation process, the temperature of the crude oil entering the atmospheric tower is 352°C, and the pressure at the top of the atmospheric tower is 0.16MPa. Usually the first-line reboiler load is controlled within the range of 1.8MMkal / hr. Usually the second-line stripping steam volume is controlled at 550Kg / hr, and the normal second-line stripping steam volume is controlled at 550Kg / hr. The heat extraction ratio of the atmospheric tower is the top of the tower: the top circulation: the first middle: the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com