Titanium leaking method for reactor for titanium sponge production

A technology of reactor and titanium sponge, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of unstable iron impurity content, labor and time-consuming, and reduced service life, so as to avoid poor quality Stability, broad application prospects, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

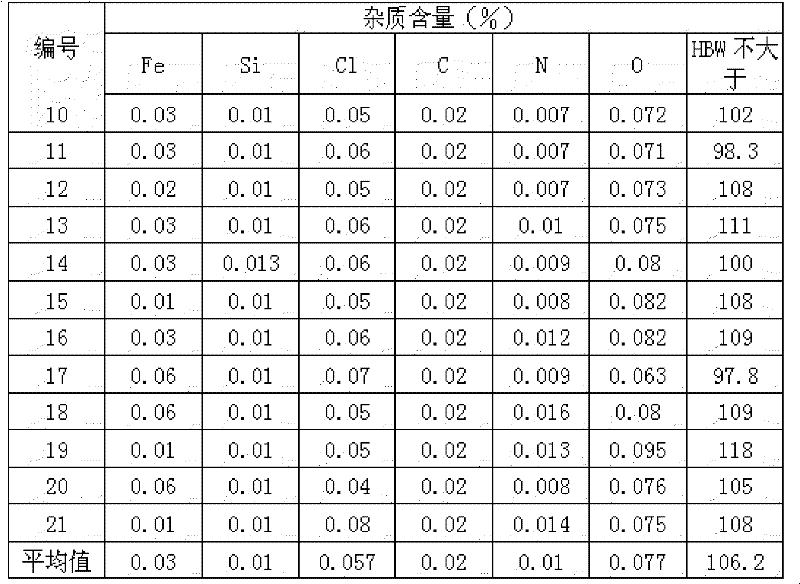

[0020] The reactor for sponge titanium production (maximum production capacity is 12t) is acid leached to remove rust, then washed and dried, and 300-1000kg of magnesium ingots are placed in the reactor, and the temperature is controlled to be 700-850°C, and then 1200-4000kg is added. Titanium tetrachloride is subjected to reduction reaction to infiltrate titanium. At the end of titanium infiltration, add magnesium ingots and liquid magnesium required for normal production of sponge titanium, add titanium tetrachloride required for normal production, and carry out normal reduction production of sponge titanium. 12 new reactors (numbered 10-21) were infiltrated with titanium respectively, and then the new reactors after infiltration of titanium were used to produce titanium sponge, and the impurity content of the produced titanium sponge was detected. The results are shown in Table 2.

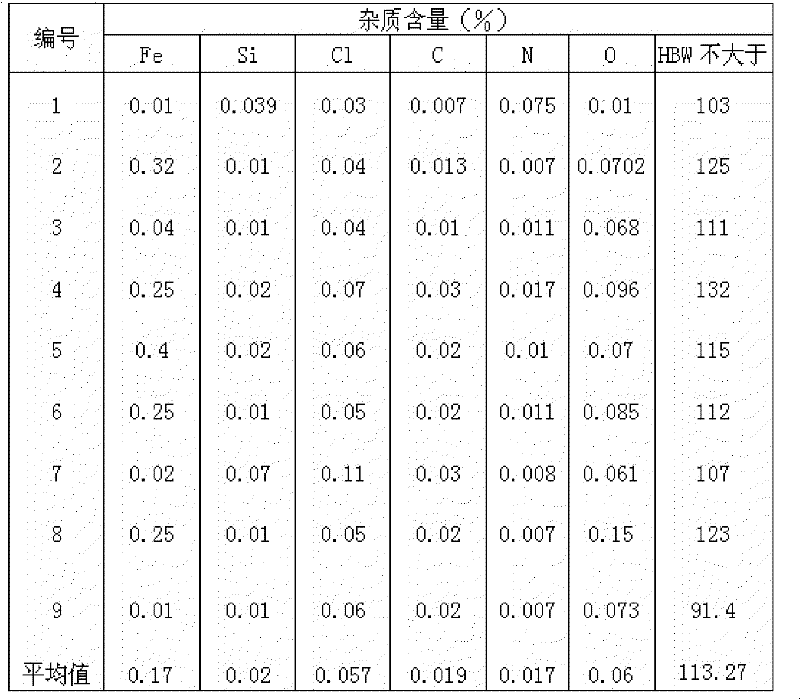

[0021] The same type of reactor is subjected to titanium infiltration by ordinary methods fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com