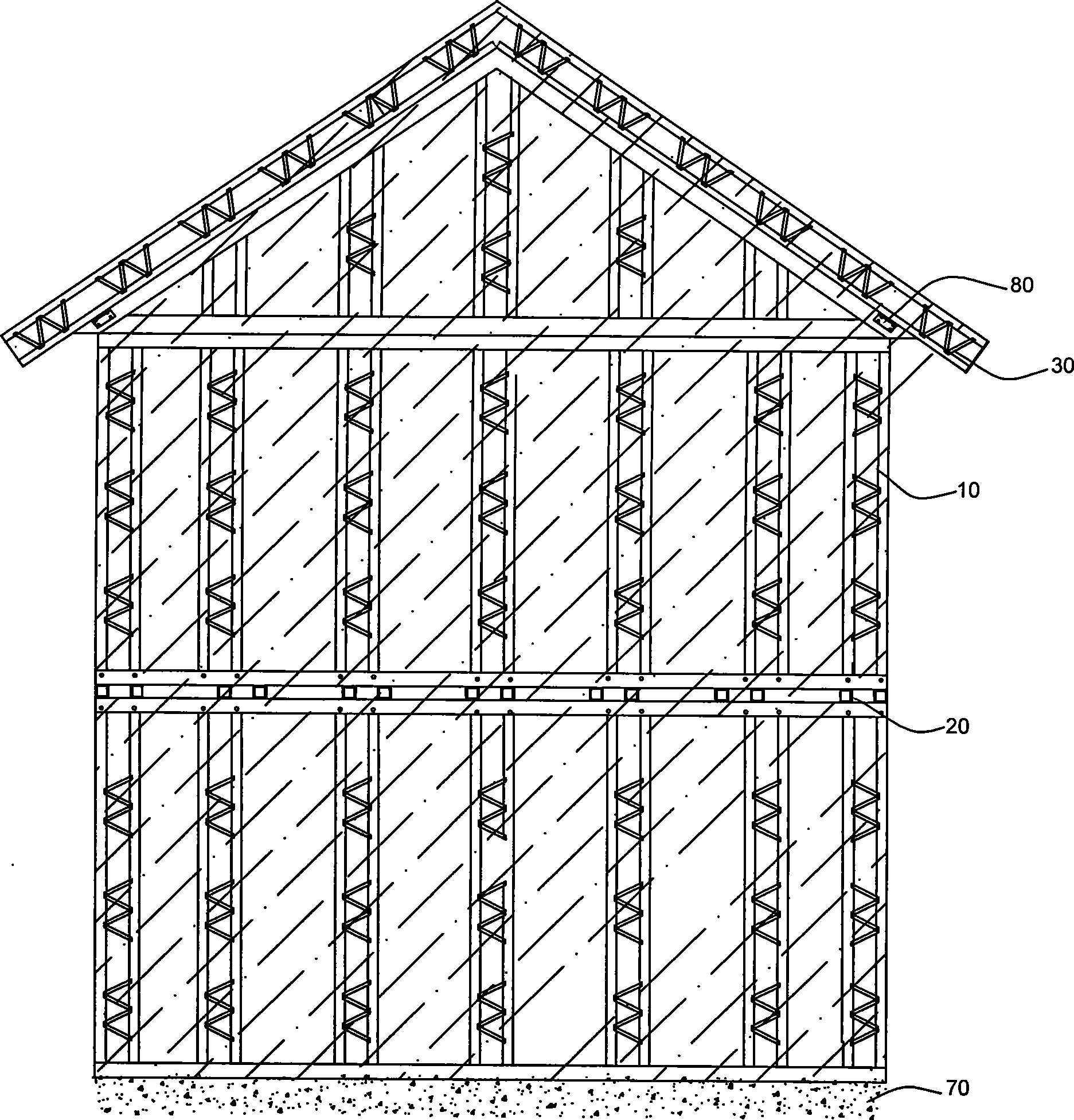

Inorganic light steel assembled energy-saving house and its construction method

A prefabricated, energy-saving house technology, applied in the direction of construction, building structure, etc., can solve the problems of low industrialization, high steel consumption, and low seismic performance, and achieve high industrialization, good seismic performance, and convenient transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

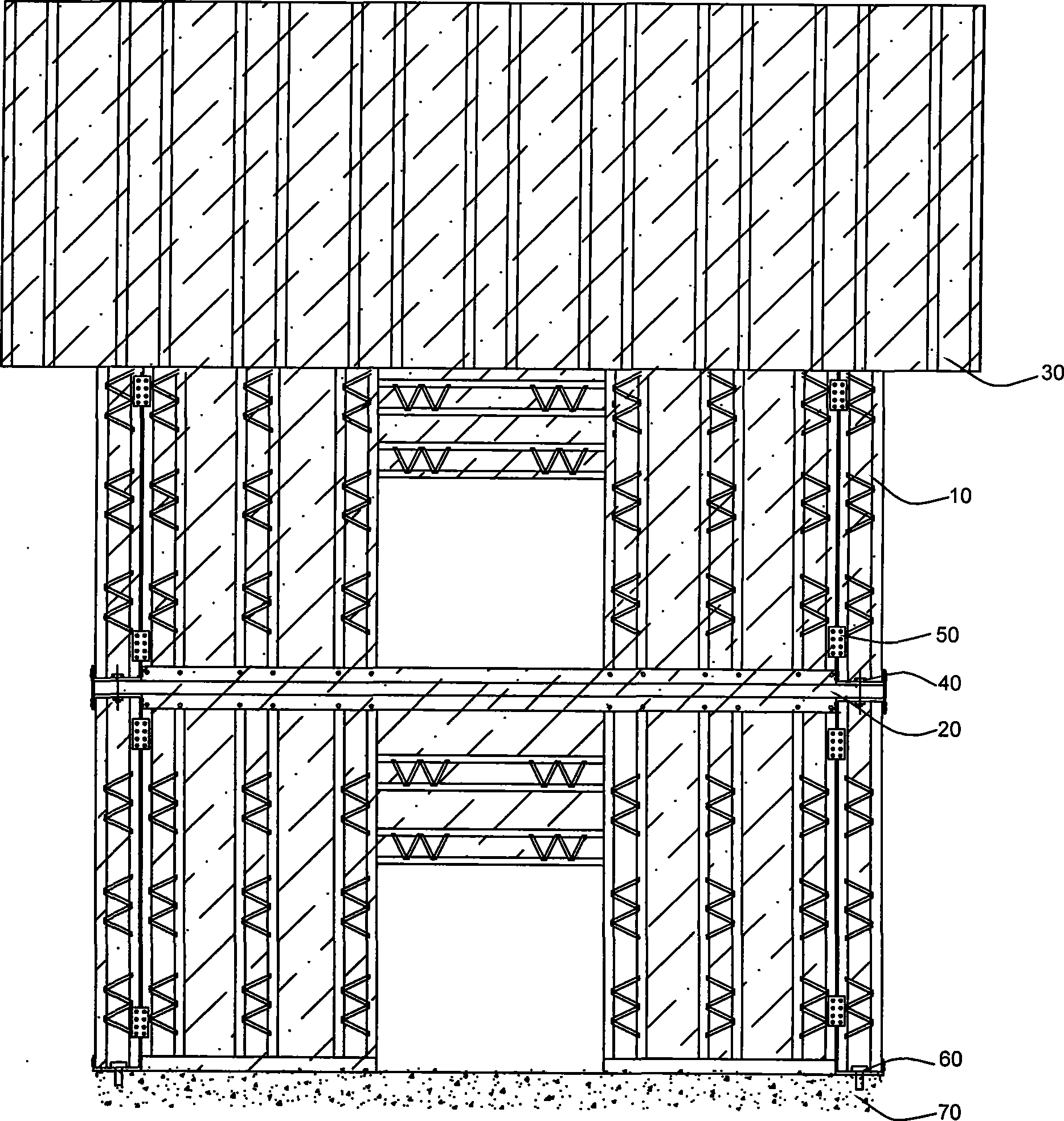

[0048] a. Sectional pouring of wall panel unit 10 and floor slab unit 20

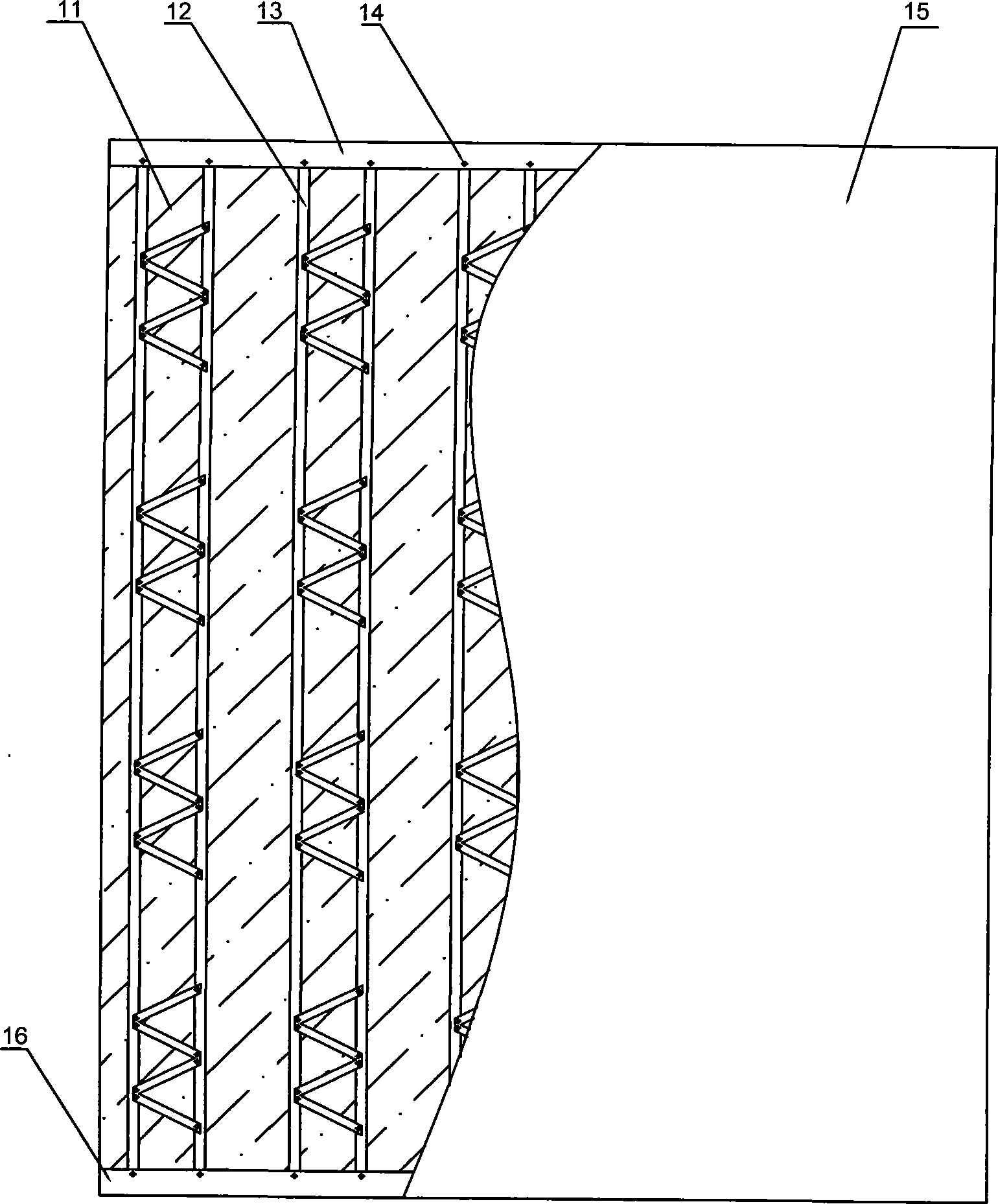

[0049] After connecting the upper and lower guide rails 13, 16 and the light steel frame 12 of the wall panel, put them into the mold box, pour the inorganic thermal insulation material 11 of the wall panel, and after the inorganic thermal insulation material 11 of the wall panel is solidified, prefabricate the unit 10 of the wall panel The wall panel unit 10 is obtained after flattening to the required size and cleaning the installation points on the prefabricated parts.

[0050] First put the lower reinforcing plate 24 flat in the mold box, then place the connected floor light steel skeleton 27 on the lower reinforcing plate 24, then pour the floor inorganic insulation material 23, then put the upper reinforcing plate 24 flat, wait After the inorganic thermal insulation material 23 of the floor is solidified, the prefabricated part of the floor unit 20 is flattened to the required size, and the instal...

Embodiment 2

[0054] a. The wall panel unit 10 and the floor slab unit 20 are poured in sections, and the construction method is the same as that of the embodiment.

[0055] b. Coating paint on the surface of the prefabricated wallboard unit 10 prepared in step a to form a finish layer 15 .

[0056] c, assembly, construction method is identical with embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com