Novel steam generation apparatus and use thereof

A technology of a steam generating device and a steam generator, which is applied in steam generation, steam generation methods, applications, etc., can solve the problems of unsafety, small steam outlet channel of heating element, and high cost, and achieve long service life, clean steam, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

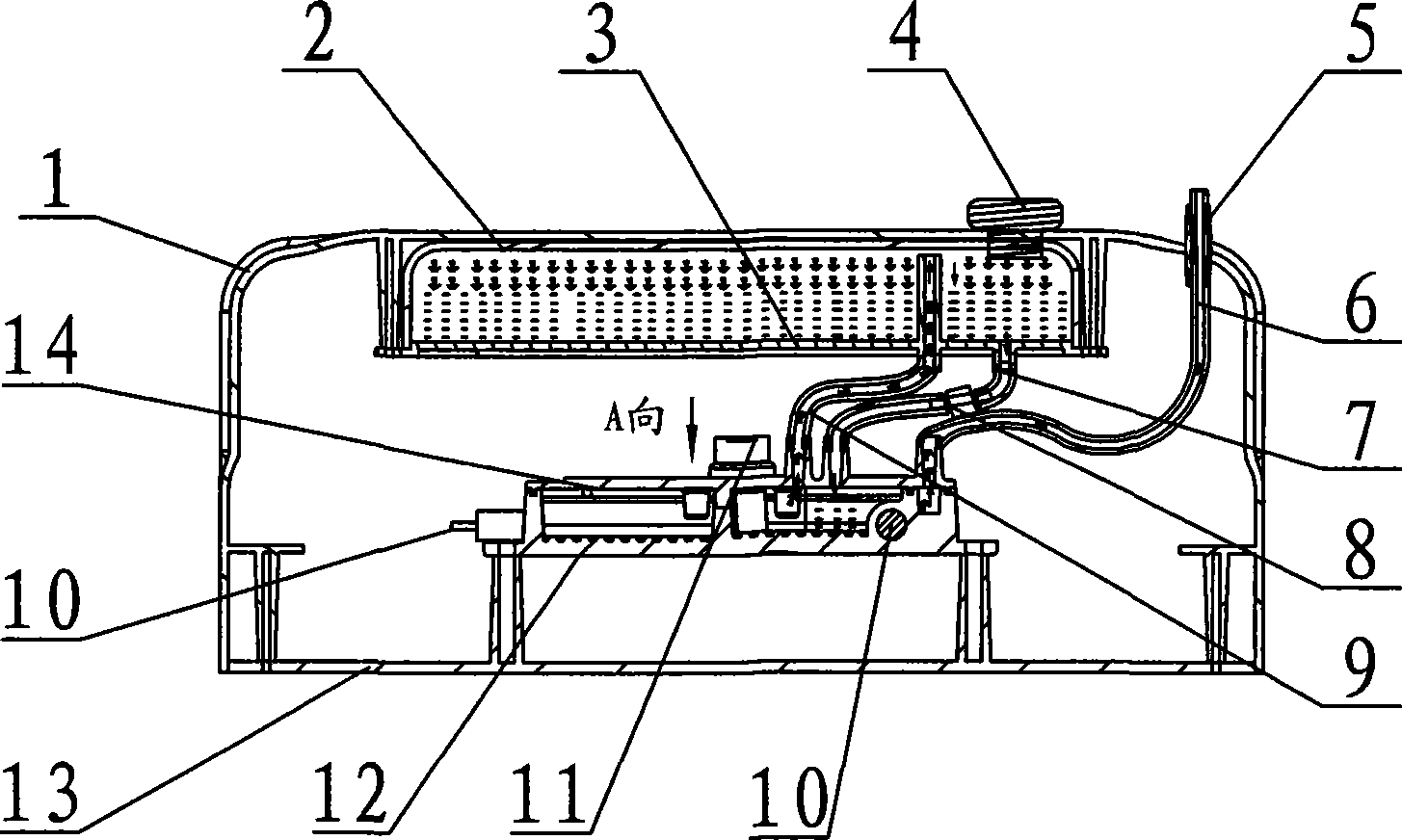

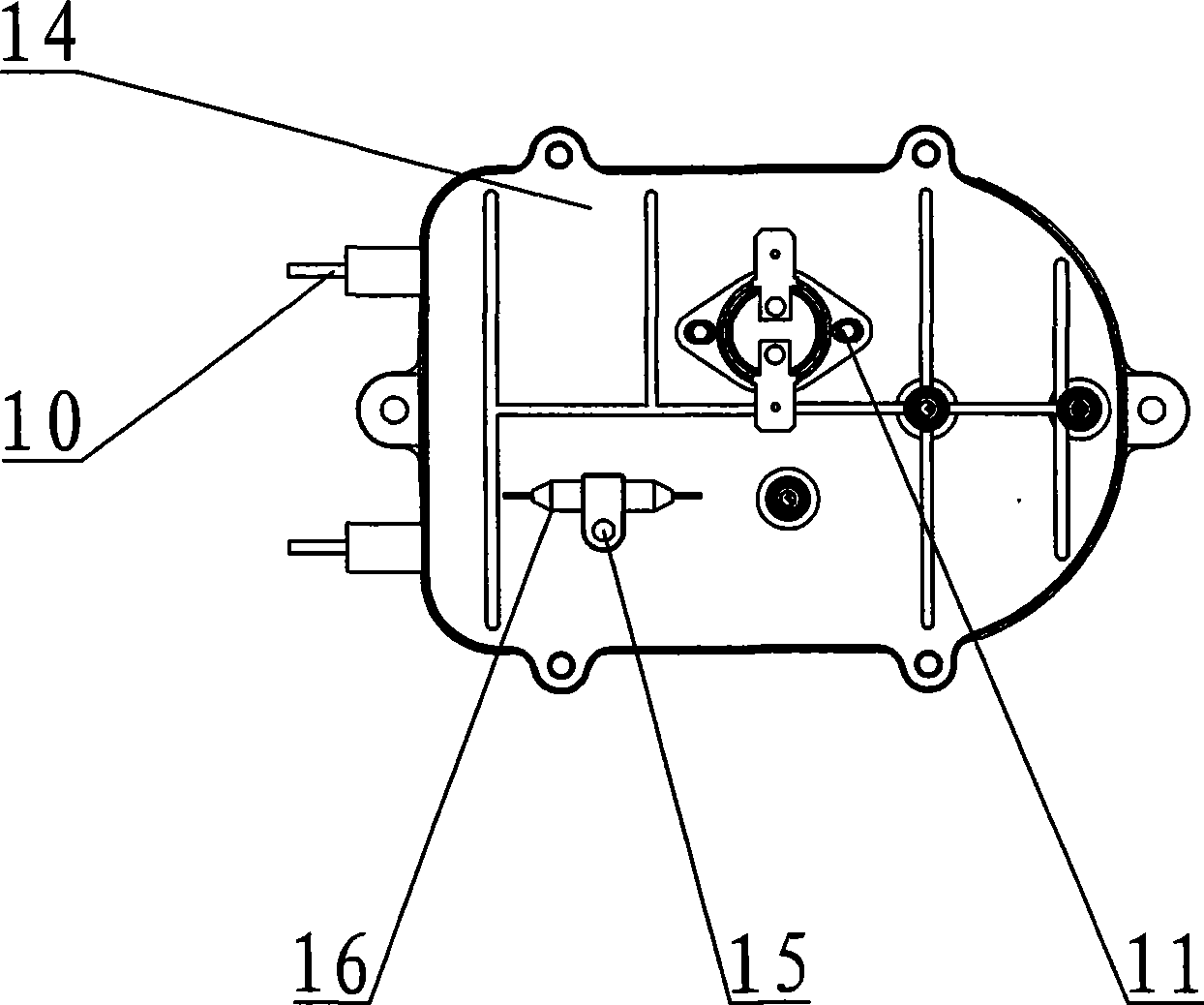

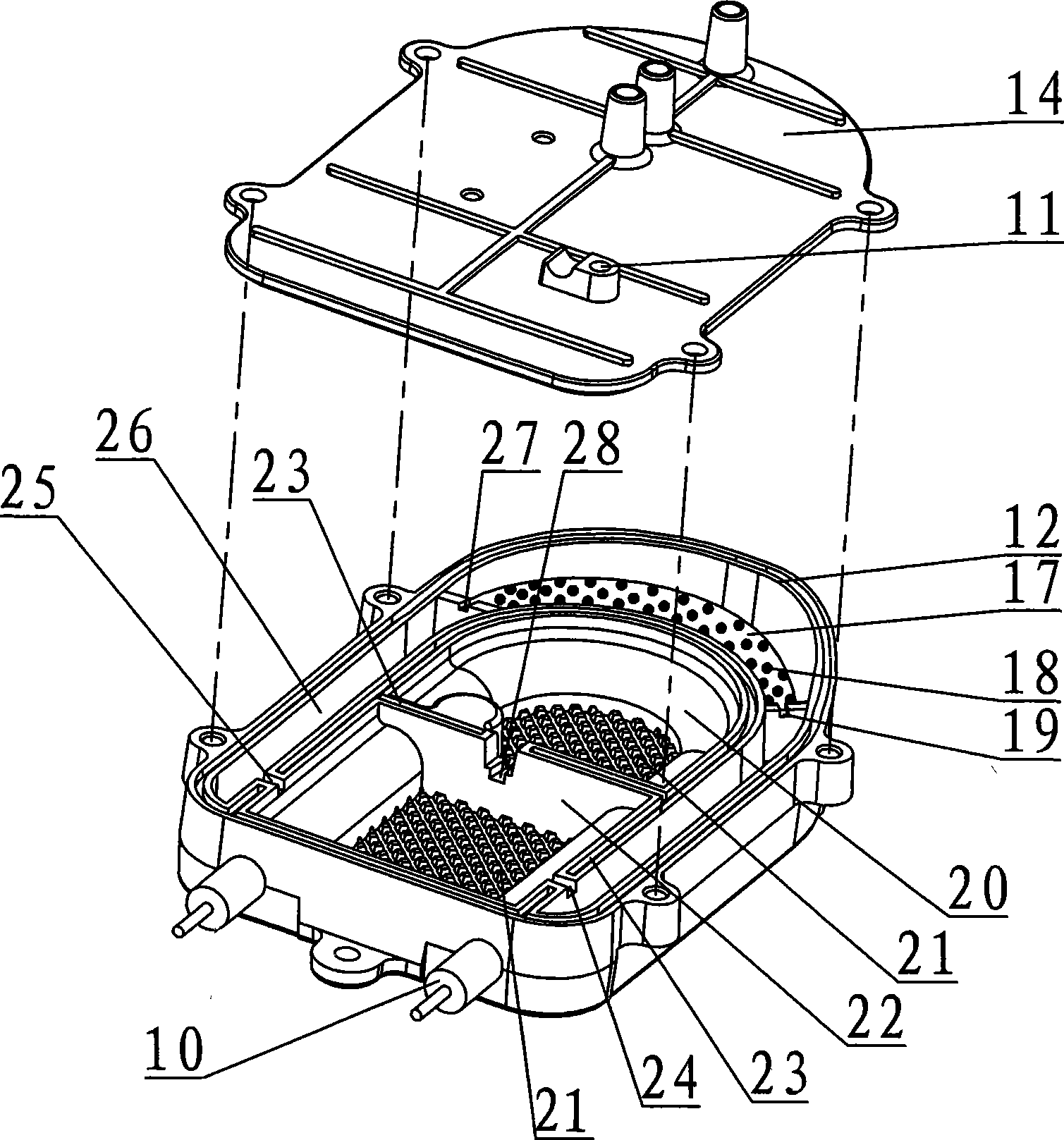

[0035] Embodiment 1 is applied to the steam mop, such as Figure 4-Figure 5 As shown, the handle 29 of the ground mop is connected to the base 1 of the steam generating device, the cleaning cloth 30 is installed below the cover plate 13, and the water tank and the heating element are arranged in the shell formed by the base and the cover plate. The steam return pipe 9 and the water inlet pipe 7 controlled by the control valve 8 are connected between them, and the steam output pipe 6 is connected to the shell cover plate by the steam cover 14 of the heating element and leads to the cleaning cloth 30 through the floor mop base. When the control valve 8 on the water inlet pipe 7 is opened, water flows into the first vaporization chamber 20 of the heating element by its own weight, and the heated heating element turns hydration into water vapor, and forms steam at a certain pressure in the first vaporization chamber. Part of it enters the second vaporization chamber 22 and then en...

Embodiment 2

[0036] Embodiment 2 is applied to a hand-held steam cleaner, such as Figure 6 As shown, a water tank and a heating element are installed in the cleaning machine housing 31, and a steam return pipe 9 and a water inlet pipe 7 with a control valve 8 are connected between the water tank and the heating element, and between the nozzle 32 and the heating element The steam output pipe 6 is connected to output the steam to the working surface. Since the steam return pipe 9 is set between the water tank and the heating element, when the control valve 8 installed on the water inlet pipe 7 is opened, the water flows into the heating element by its own weight. A vaporization chamber 20, the heated steam converts water into water vapor, forms steam at a certain pressure in the first vaporization chamber, and part of the steam enters the second vaporization chamber 22 and then enters the third vaporization chamber 26, with a certain pressure and high temperature The dry steam enters the work...

Embodiment 3

[0037] Embodiment 3 is applied to a steam iron, such as Figure 7 As shown, a steam output pipe 6 is connected between the iron assembly 33 and the steam generating device, and the steam is input to the iron assembly, and sprayed to the working surface after heating. Since the steam return pipe 9 is connected between the water tank and the heating element, when the When the control valve 8 on the water inlet pipe 7 is installed, the water flows into the first vaporization chamber 20 of the heating element by its own weight, and the heated steam turns the water into water vapor and forms steam with a certain pressure in the first vaporization chamber, and part of the steam enters the second vaporization chamber. The steam chamber 22 then enters the third vaporization chamber 26 to form high-temperature dry steam with a certain pressure, and enters the working surface through the steam output pipe 6 and then the iron assembly 33, and another part of the steam flows back to the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com