Electric power plant condenser ball cleaning on-line monitoring device based on optical fiber sensing technology

The invention relates to an optical fiber sensing technology and a monitoring device technology, which is applied to the field of on-line monitoring devices for cleaning rubber balls of condensers in power plants, and can solve the problems of difficulty in inspecting and recovering rubber balls to detect wear of rubber balls, high purchase price of cleaning systems, and increased manufacturing costs. Achieving the best cleaning effect, light weight and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

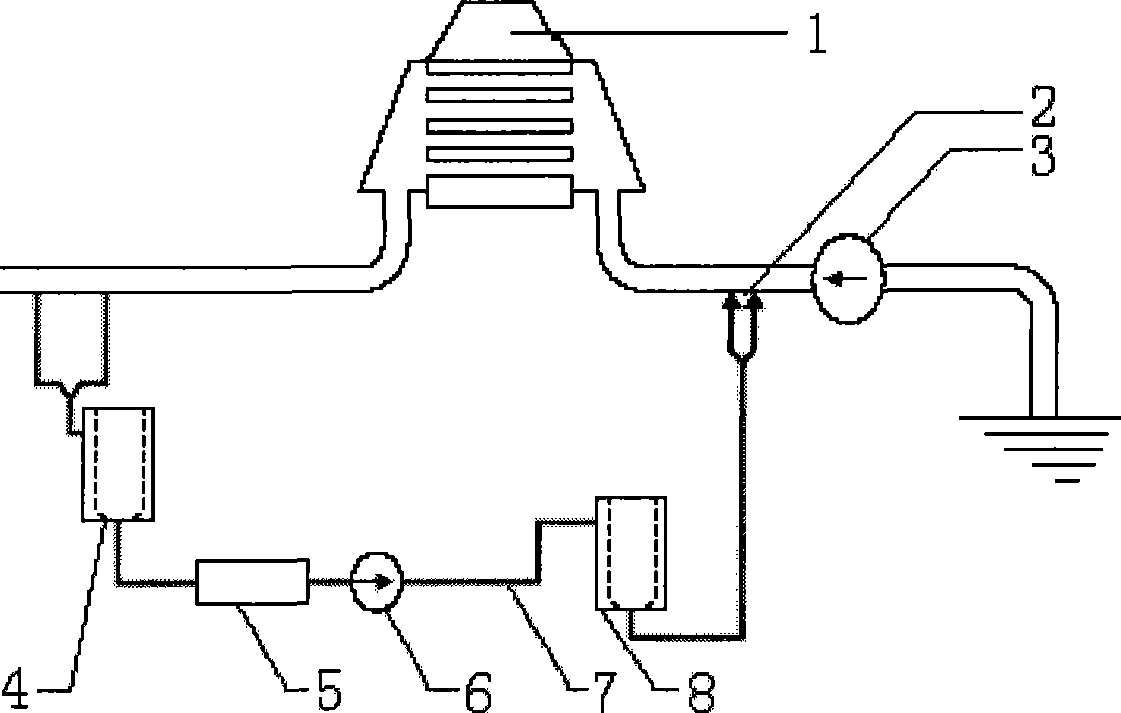

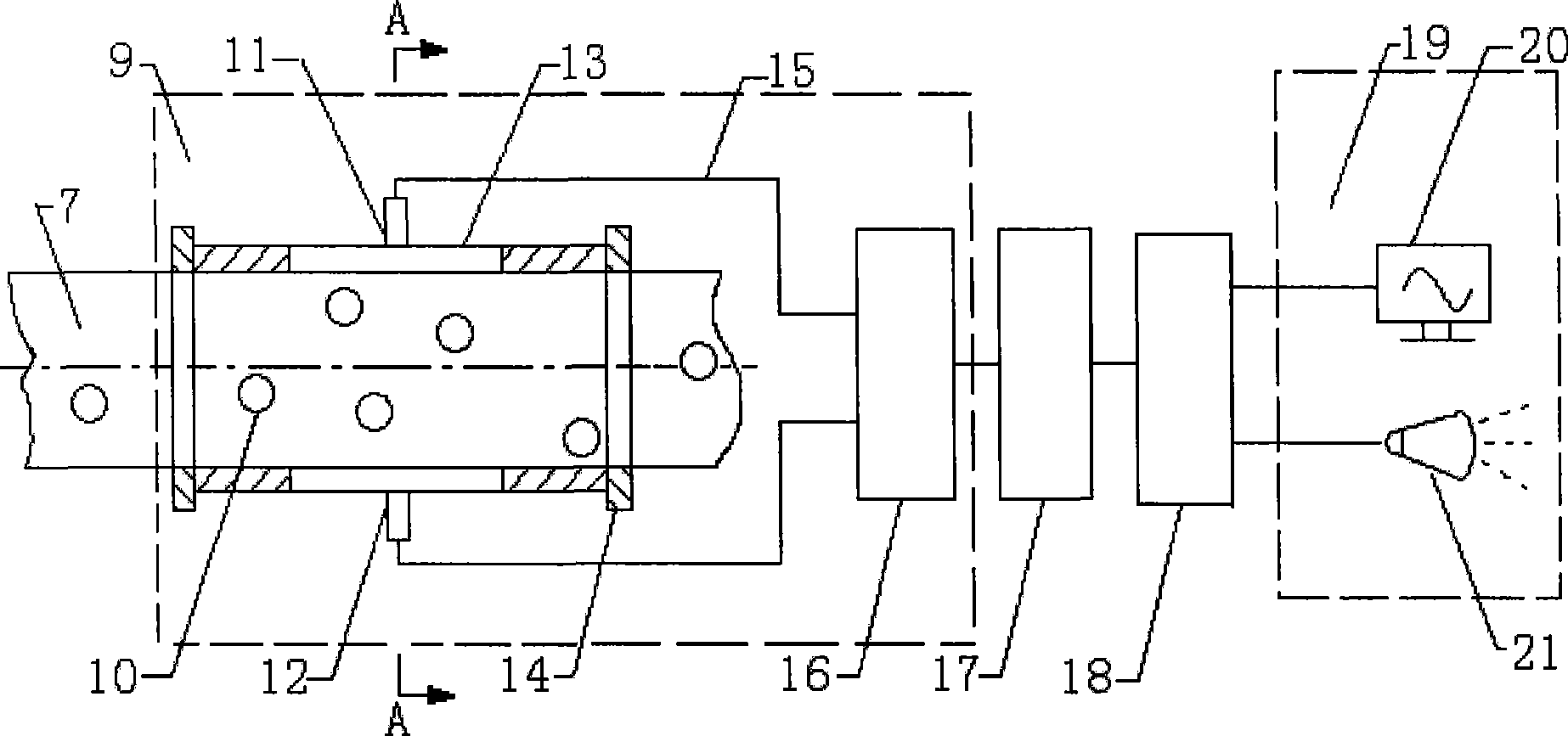

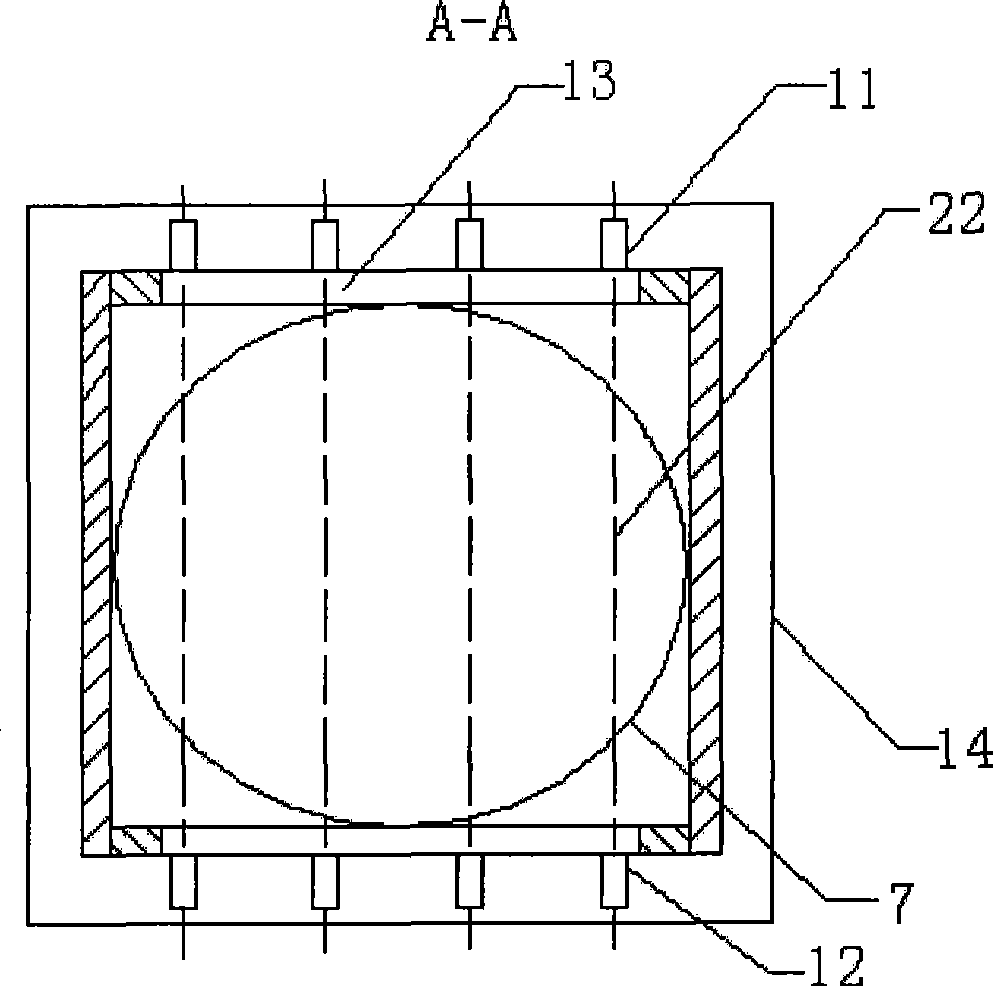

[0016] according to figure 1 The specific structure of the present invention will be described in detail with the embodiments. The on-line monitoring device for cleaning rubber balls in a power plant condenser based on optical fiber sensing technology includes a monitoring device 5 connected to a rubber ball circulation pipeline of the rubber ball cleaning device and a monitoring control circuit thereof. Such as figure 1 As shown, the rubber ball cleaning device of the condenser 1 is composed of a rubber ball nozzle 2, a circulating water pump 3, a ball collecting chamber 4 with a ball collecting net, a monitoring device 5, a rubber ball pump 6, a rubber ball conveying pipeline 7, a ball loading Room 8 and so on. The monitoring device 5 is used as an additional part of the rubber ball cleaning device, and its housing is connected in the rubber ball circulation pipeline of the rubber ball cleaning device through flanges 14 at both ends. In this embodiment, in order to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com