Dynamic full performance test system for multifunctional belt balance

A test system and belt scale technology, applied in the field of test platforms, can solve the problems of lack of versatility, risk of belt scale quality determination, lack of detection methods, etc., and achieve the effects of less equipment investment, expansion of belt speed coverage, and less land occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

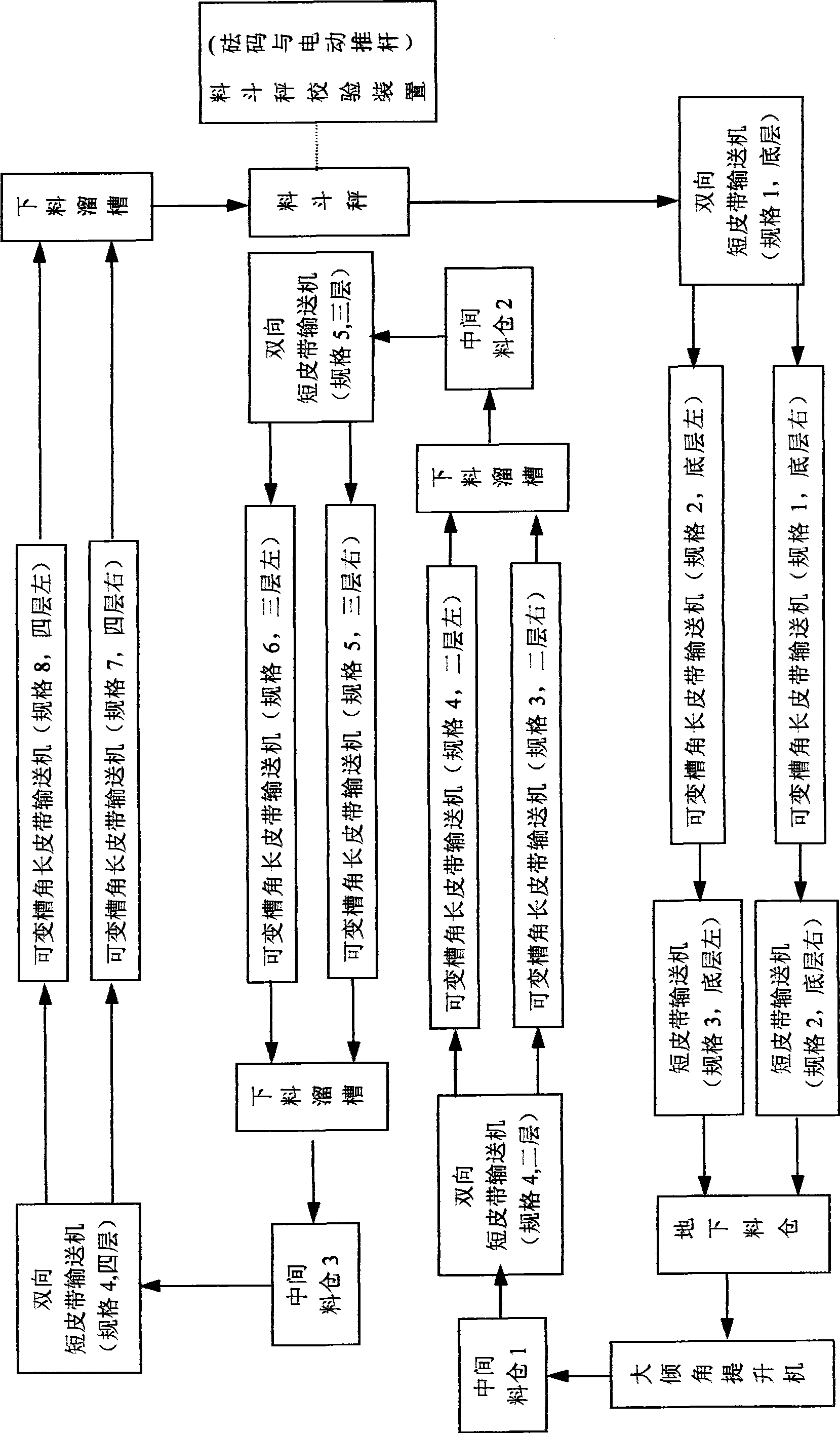

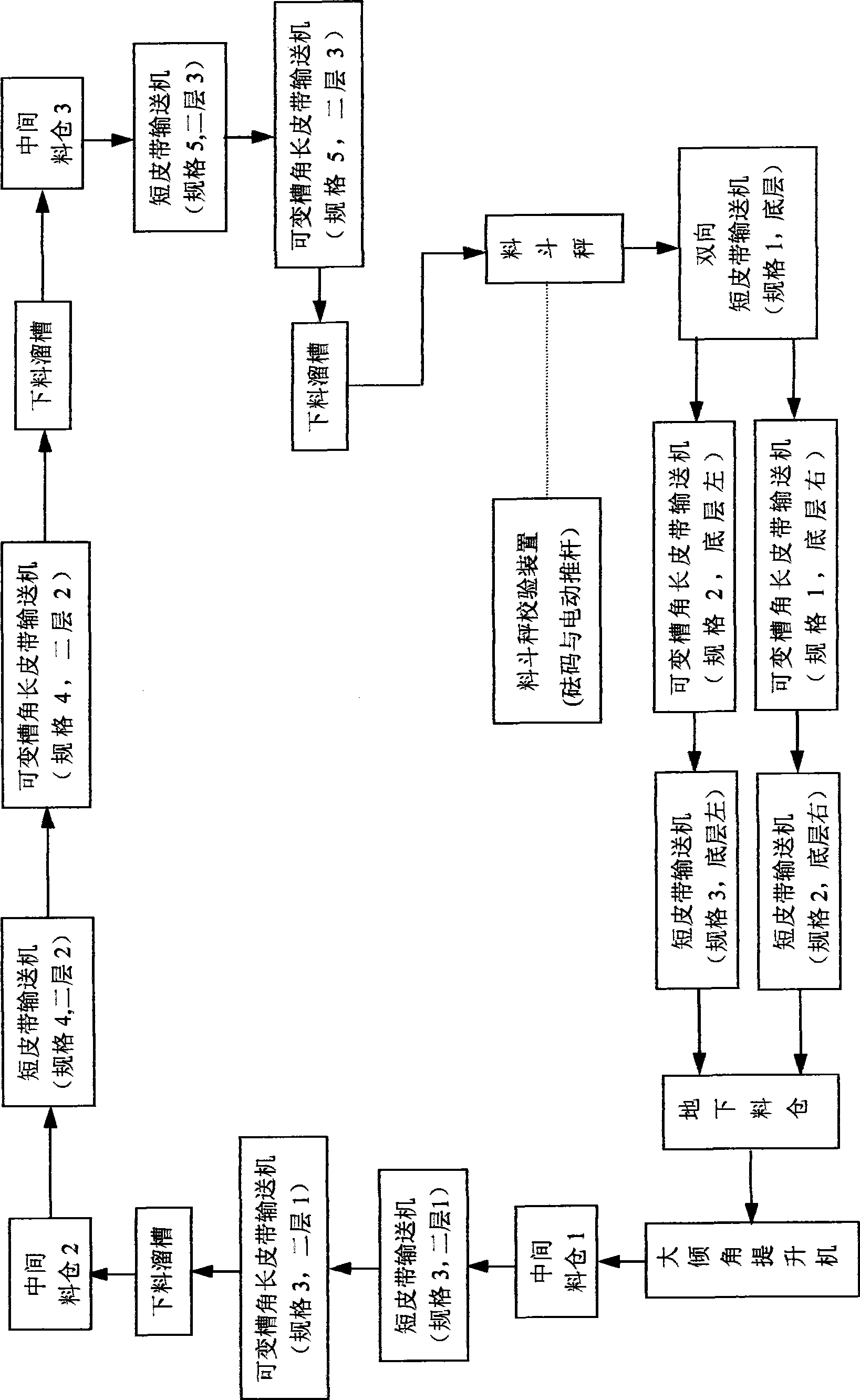

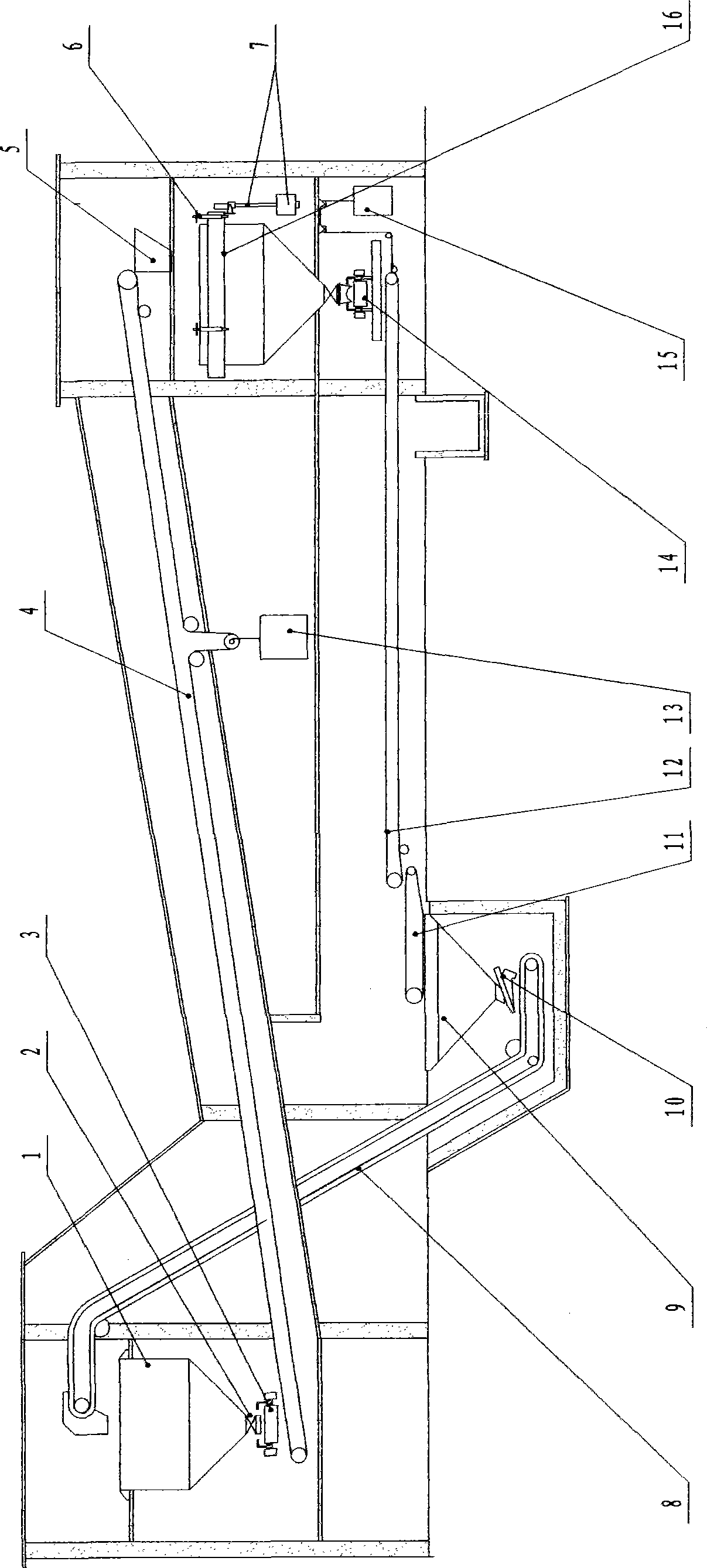

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] This embodiment is a double-layer double-row reciprocating return conveyor layout, equipped with 4 adjustable three-section grooved long belt conveyors with different bandwidths, of which the upper conveyor 4 and the lower conveyor 12 are one on each side, which can be embedded. Measuring belt scales with four kinds of bandwidth specifications (650mm, 800mm, 1000mm, 1200mm) and two trough angles (30° or 35°); and 4 sets of short belt conveyors, including: middle silo 1 discharge port Two-way quantitative feeder at ①3, two-way quantitative feeder at the discharge port of the hopper scale ②14, quantitative feeder 11 between the lower long belt conveyor and the underground silo (one left and right).

[0021] The bulk material in the intermediate silo 1 reaches the two-way short belt conveyor 3 through the silo valve 2, and quantitatively fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com