Method for wax-sealed measurement of asphalt mixture bulk density

A technology of bulk density and asphalt mixture, which is applied in the direction of material weighing, measuring devices, and analyzing materials, etc., can solve the problems of test detection failure, poor practical operability, confusion of opening gaps and structure depth, etc., to ensure accurate The effect of reliability, test results are true and reliable, and the brushing method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]Embodiment 1: measure the density of half-open asphalt mixture specimen:

[0044] Use an electronic balance with a measuring range of 4000g and a sensitivity of 0.01g to weigh the air weight ma=1209.5g of the dry test piece;

[0045] Melt the paraffin to the required temperature of 50-60°C, dip the paraffin melt with a brush and apply it evenly on the surface of the test piece, pay attention to controlling the wax temperature and the strength of the operation, so that the wax film is formed on the surface of the open pores, do not put the wax melt Point into the open pores;

[0046] Dry the wax-sealed test piece at room temperature for 30 minutes, adjust the wax temperature to 60-65 ° C, dip the wax melt in a vertical manner with the hand-held test piece, then turn the test piece and repeat in the same way;

[0047] Carefully check the sealed test piece, if there is any hole left, fill it with a brush dipped in wax;

[0048] When the surface of the test piece is dry, r...

Embodiment 2

[0054] Embodiment 2: Density of open-graded asphalt mixture:

[0055] Use an electronic balance with a measuring range of 4000g and a sensitivity of 0.01g to weigh the air weight ma=1150.66g of the dry test piece;

[0056] Melt the paraffin to the required temperature of 50-60°C, dip the paraffin melt with a brush and apply it evenly on the surface of the test piece, pay attention to controlling the wax temperature and the strength of the operation, so that the wax film is formed on the surface of the open pores, do not put the wax melt Point into the open pores;

[0057] Dry the wax-sealed test piece at room temperature for 30 minutes, adjust the wax temperature to 60-70 ° C, dip the wax melt in a vertical manner with the hand-held test piece, then turn the test piece and repeat in the same way;

[0058] Carefully check the sealed test piece, if there is any hole left, fill it with a brush dipped in wax;

[0059] When the surface of the test piece is dry, re-weigh the wax s...

Embodiment 3

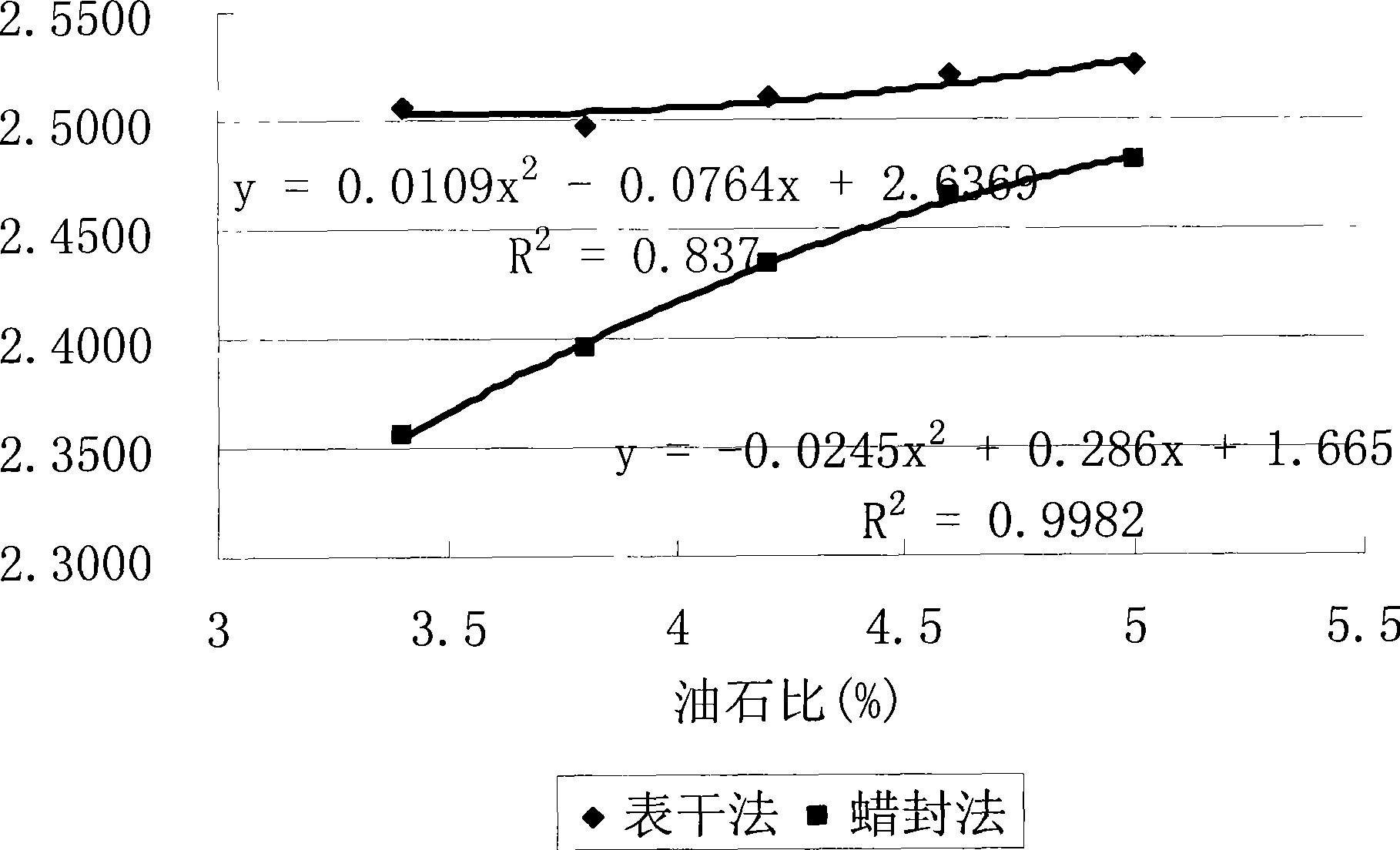

[0065] Embodiment 3: the contrast of different measuring methods:

[0066] 3-1 The wax sealing method of the present invention is compared with the surface dry method

[0067] Use the same specimens first to measure the surface-dry bulk density of the group of specimens according to the determination method of the surface-dry bulk density stipulated in the "Test Regulations for Highway Asphalt and Asphalt Mixtures".

[0068] Dry the test pieces whose surface dry density has been measured with an American corelok vacuum dryer, re-weigh the air weight, and measure the wax-sealed bulk density of each test piece according to the steps specified in this method.

[0069] The bulk density measured under the two methods is compared in Table 1 below, and figure 1 .

[0070] Table 1 Determination of bulk density by different methods

[0071]

[0072] It can be seen from the test results that when the surface-dry method is used to measure the asphalt mixture when the asphalt ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com