Product quality on-line soft-measuring method for industrial fluidized bed gas-phase polythene apparatus

A technology of product quality and soft measurement, applied in the direction of material inspection products, etc., can solve the problems that product quality cannot be directly measured, and it is difficult to realize online monitoring of product resin quality control devices, so as to improve the accuracy of soft measurement and facilitate on-site application. Technology clear line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution details of the present invention will be described in detail one by one below, and the purpose and effect of the present invention will be more obvious.

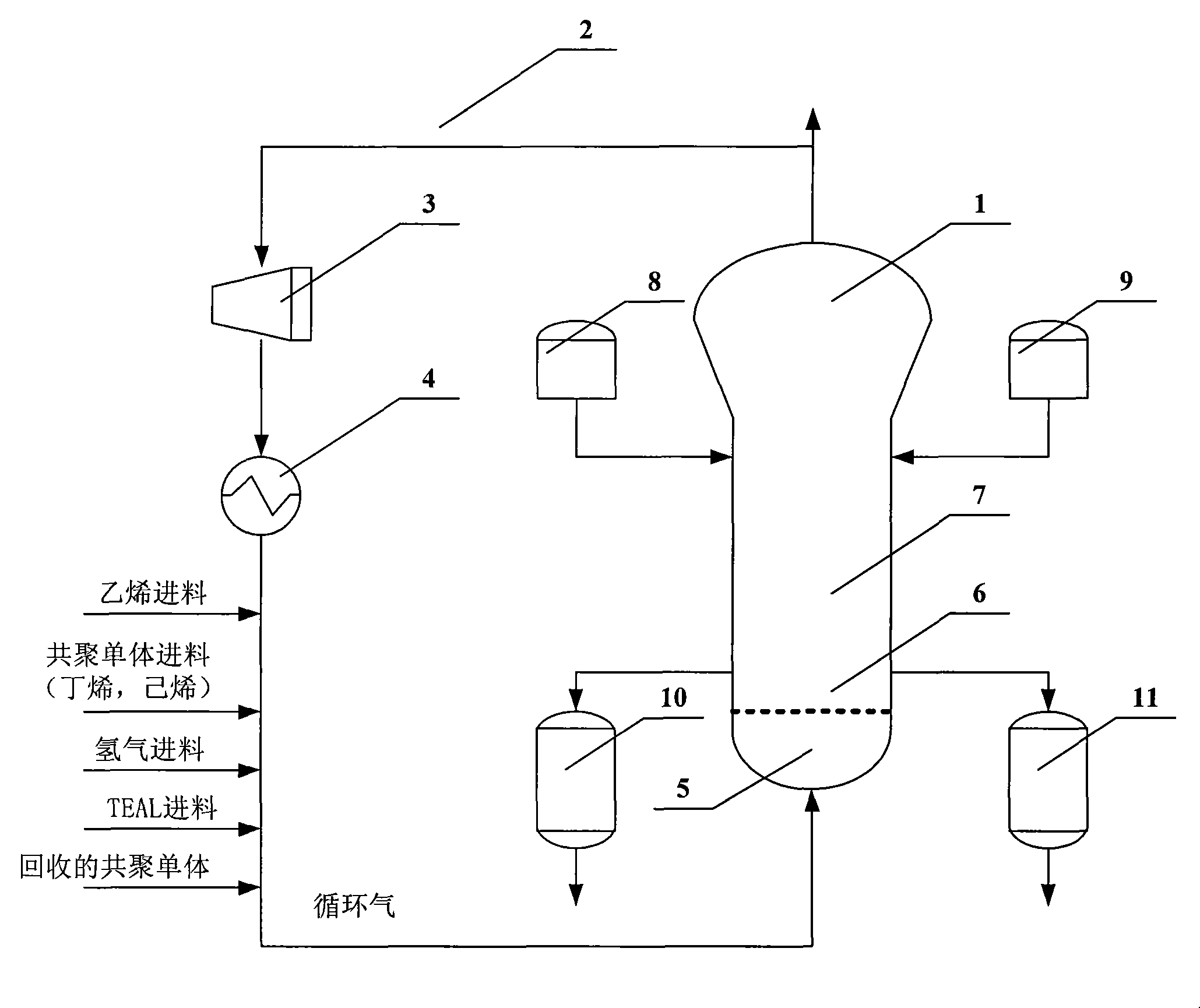

[0024] figure 1 It is a schematic diagram of a common industrial fluidized bed gas phase polyethylene production device in China. The main equipment is composed of gas phase fluidized bed reactor 1, circulating gas pipeline 2, circulating gas compressor 3, and circulating gas heat exchanger 4. The equipment is composed of The circulating gas pipelines are connected in series. Wherein, the gas-phase fluidized bed reactor comprises a reactor mixing chamber 5, a reactor distribution plate 6, a fluidized bed layer 7, a product discharge tank A 8, a product discharge tank B 9, a catalyst feeder A 10, and a catalyst feeder B 11, both attached to the inside and outside of the reactor. During the production process, the circulating gas containing monomers, comonomers and other components first enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com