Electric discharge lamp device and lighting apparatus

A technology of lighting device and discharge lamp, applied in the field of lighting equipment and discharge lamp lighting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

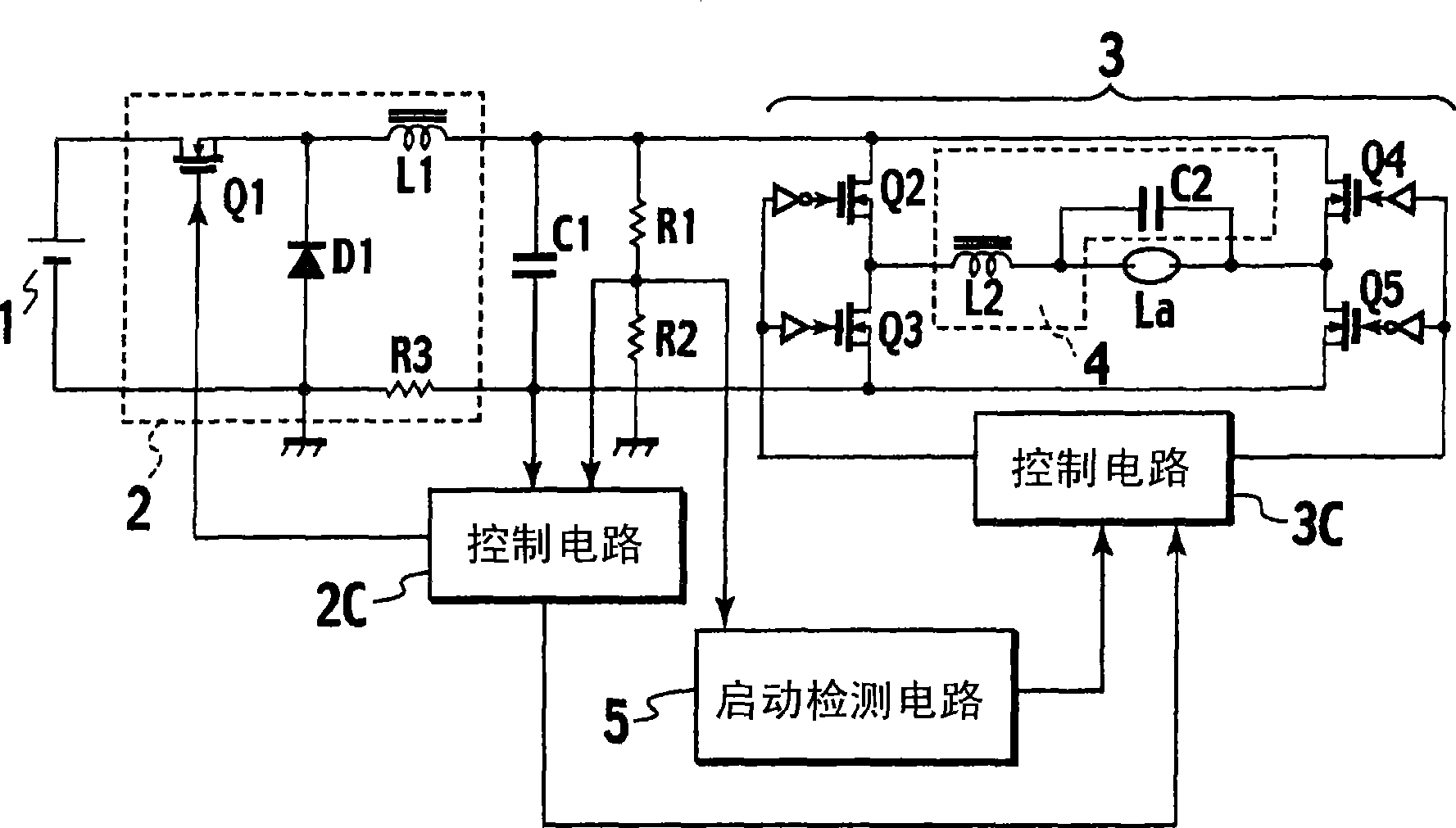

[0030] figure 1 The circuit configuration of the discharge lamp lighting device according to the first embodiment of the present invention is shown. This discharge lamp lighting device is composed of the following parts: DC power supply 1; DC / DC converter 2 for converting the power supply voltage of DC power supply 1 into a desired DC voltage; Smoothing capacitor C1; DC / AC converter 3 that converts DC voltage smoothed by smoothing capacitor C1 into AC voltage; has a resonant circuit composed of resonant capacitor C2 and resonant inductance L2 that contributes to resonant operation, and converts DC / AC The output of the inverter 3 is supplied to the starting circuit 4 for the discharge lamp La; the control circuit 2C for controlling the DC / DC converter 2 ; and the control circuit 3C for controlling the DC / AC converter 3 .

[0031] on the circuit with Image 6 The difference of the discharge lamp lighting device is that, figure 1 The shown discharge lamp lighting device inclu...

no. 2 Embodiment approach

[0066] Next, a discharge lamp lighting device according to a second embodiment of the present invention will be described. In addition, since the circuit configuration of the discharge lamp lighting device of the second embodiment is the same as that of the first embodiment, description thereof will be omitted. In addition, the same part as the above-mentioned first embodiment can be regarded as omitting the detailed description.

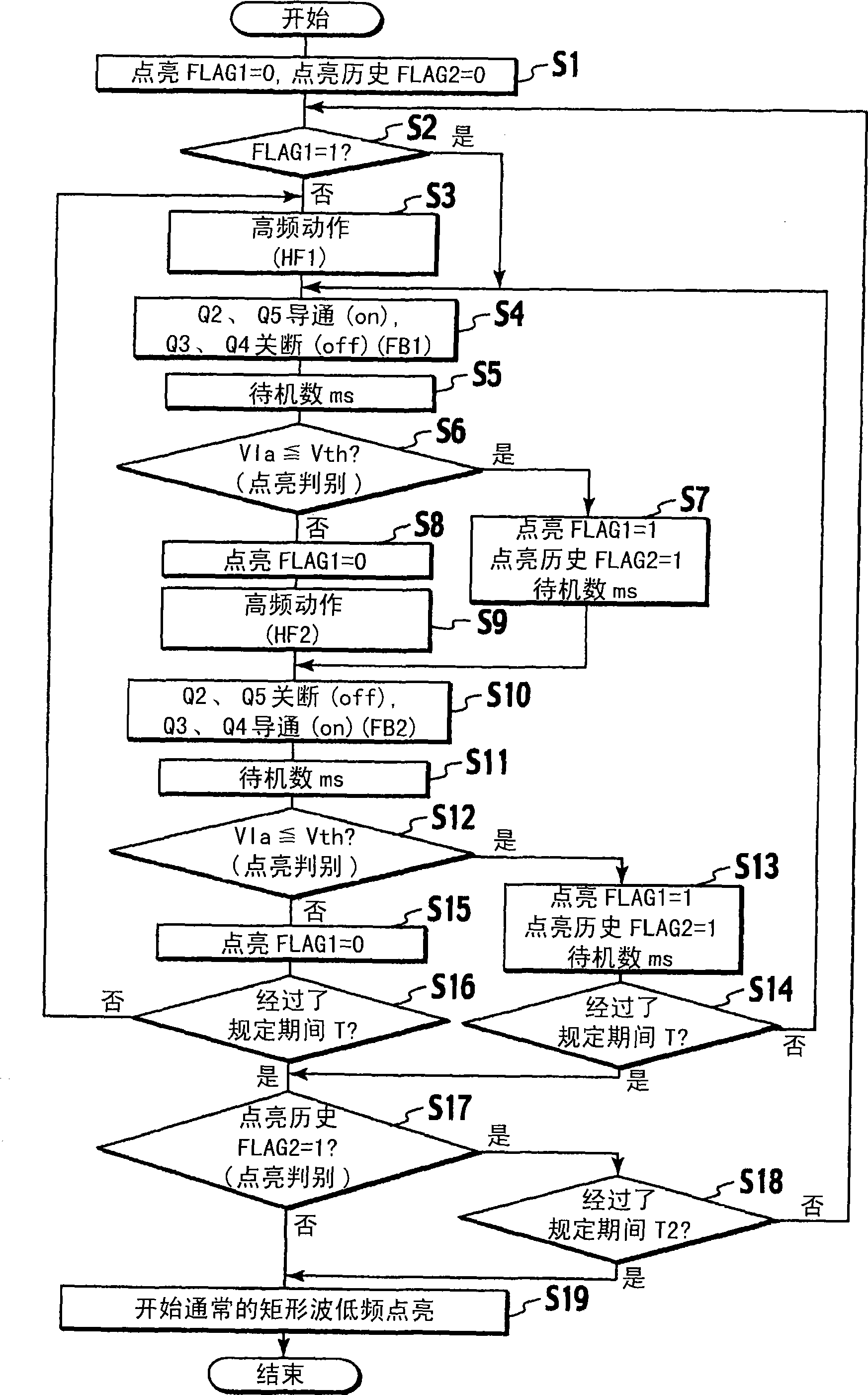

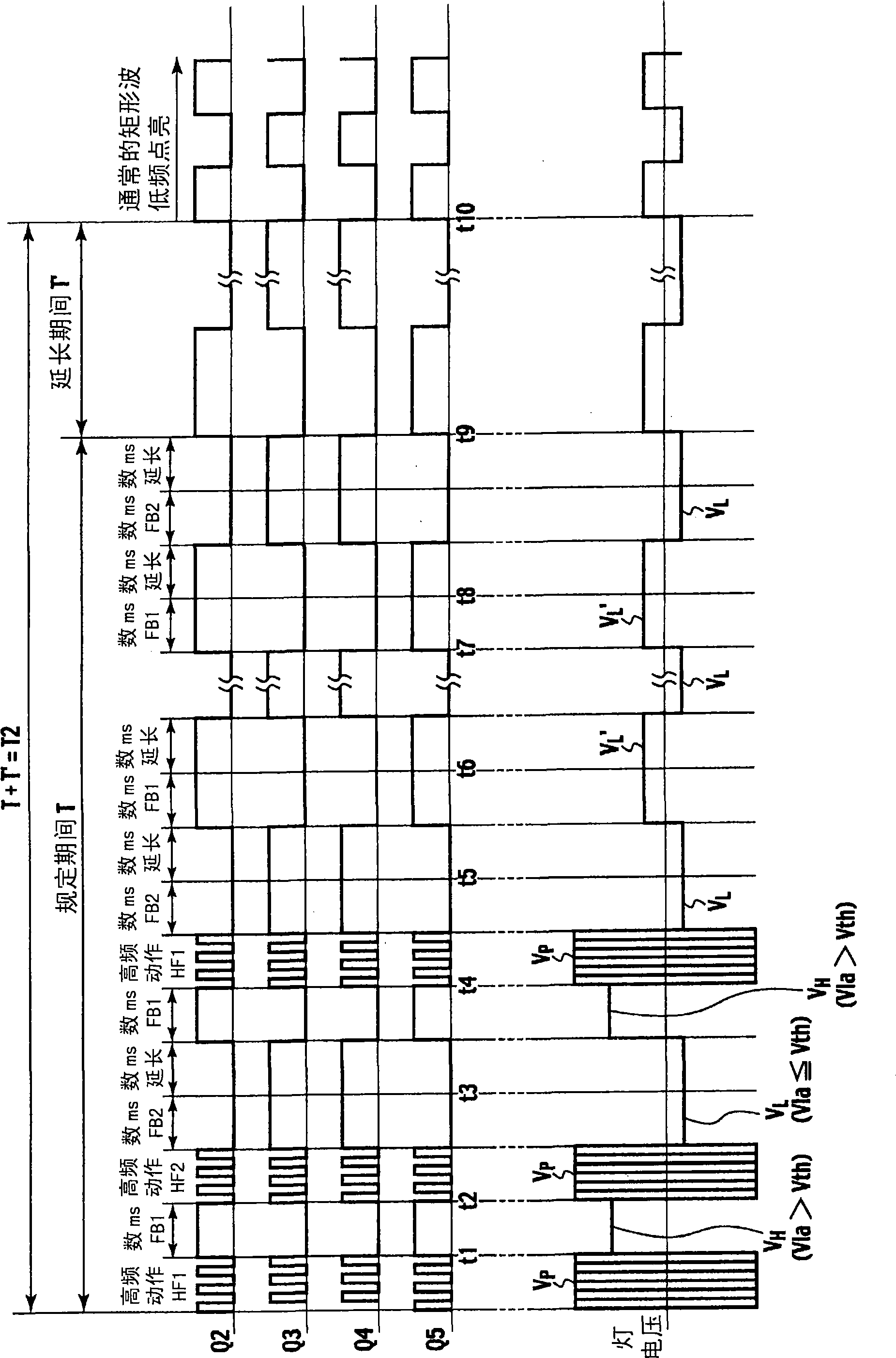

[0067] Figure 4 A control flowchart showing the operation of main parts of the second embodiment, Figure 5 The operation of the switching elements Q2 to Q5 and the waveform of the lamp voltage are shown.

[0068] Figure 4 Although the control using the lighting flag (FLAG1) and lighting history flag (FLAG2) is not shown in the figure, the figure 2 The processes of step S7, step S13, step S17, and step S18 are shown. That is, the present embodiment also extends the predetermined period T to T2 (>T) when it is determined that the discharge la...

no. 3 Embodiment approach

[0075] The discharge lamp lighting device according to any one of the first embodiment and the second embodiment can be incorporated in a lighting fixture to which the high-pressure discharge lamp La is attached, or can be used as an external ballast provided separately from the lighting fixture. In addition, such a lighting fixture may be combined with a human sensor or a brightness sensor to constitute a lighting system that controls light output based on the sensor. In addition, it can also be combined with a timer to form a lighting system that controls light output according to a time period. In addition, it can also be used in a projection-type image display device using a high-pressure discharge lamp La as a light source or in a vehicle headlamp lighting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com