Storage element and storage device

A storage element and storage device technology, applied in electrical elements, electric solid state devices, semiconductor devices, etc., can solve the problem of MRAM power consumption and other problems, and achieve the effects of improving resistance value retention performance, large capacity, and increasing times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Specific examples of the present invention will be described below.

[0076] With respect to the memory cell array 20 and the memory element 10 in the above-mentioned embodiment, different samples were fabricated to study their properties.

[0077]

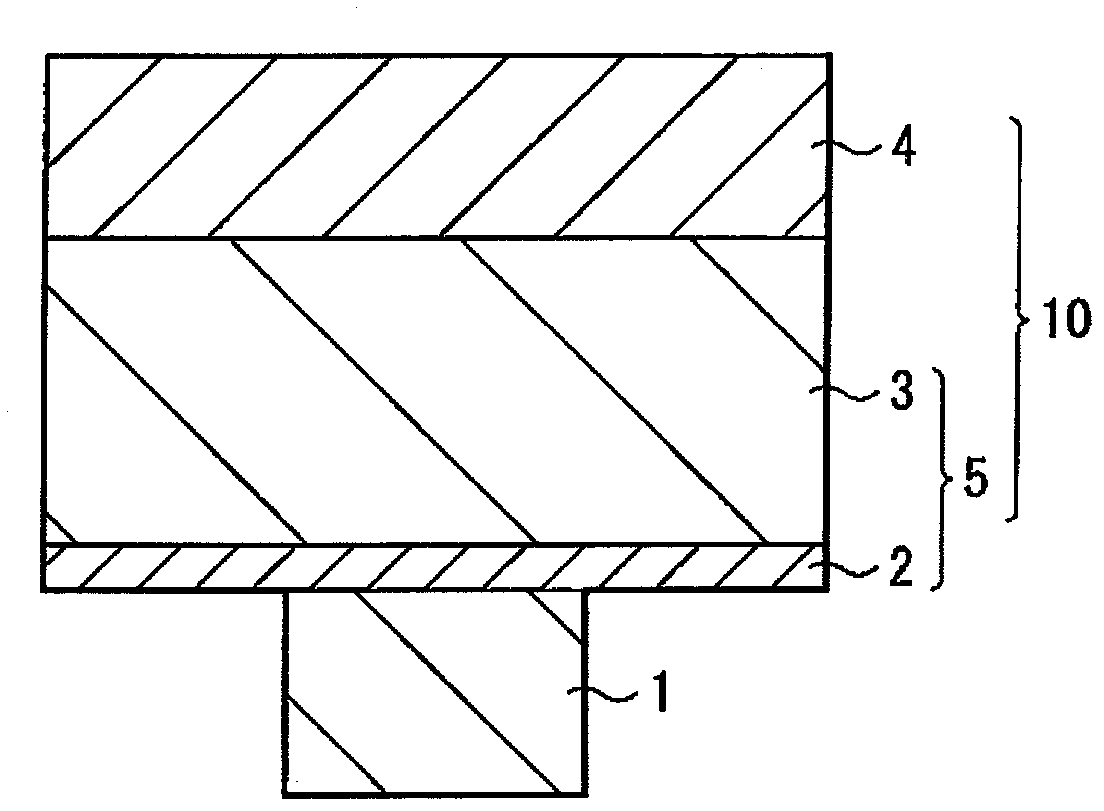

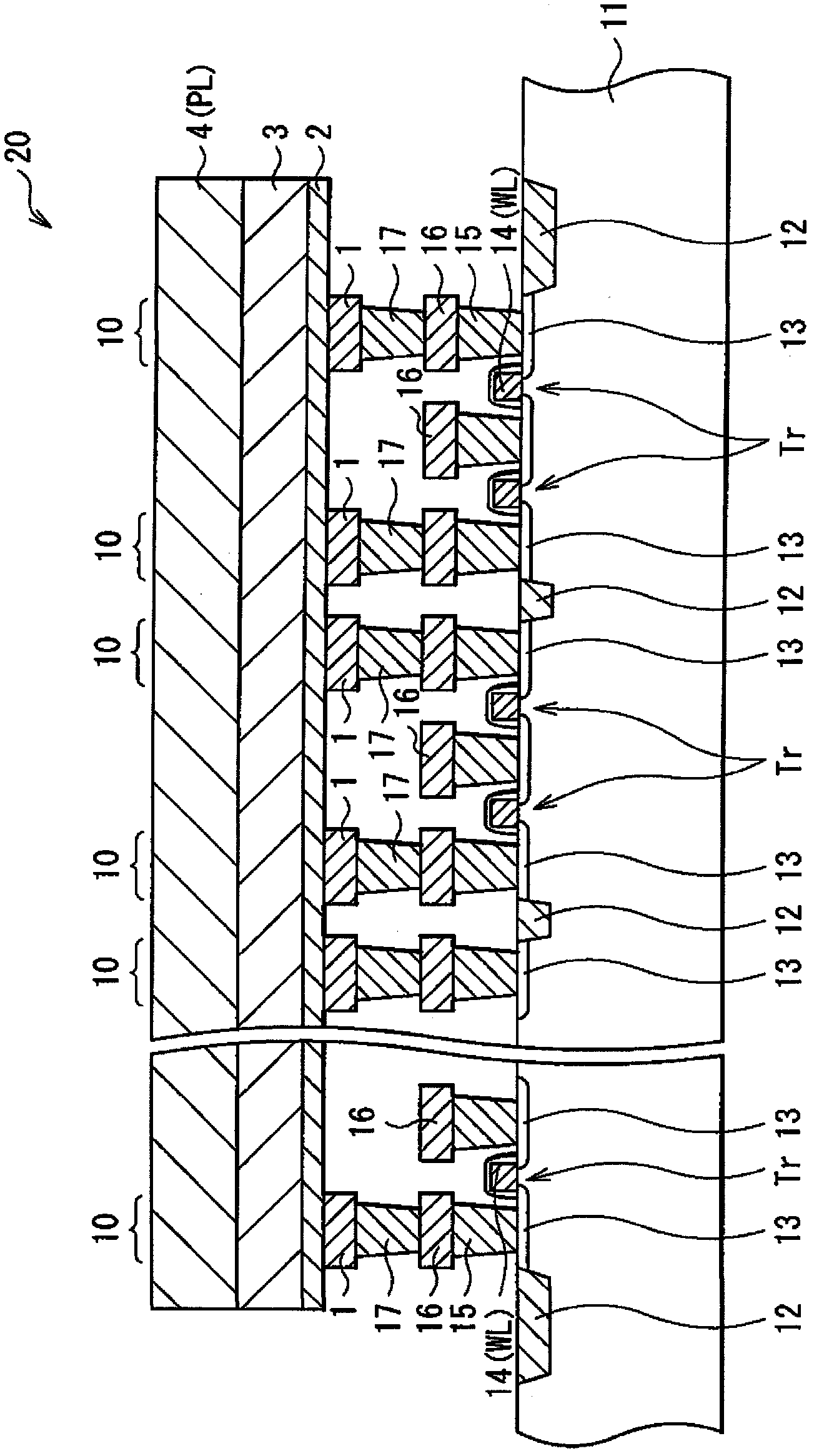

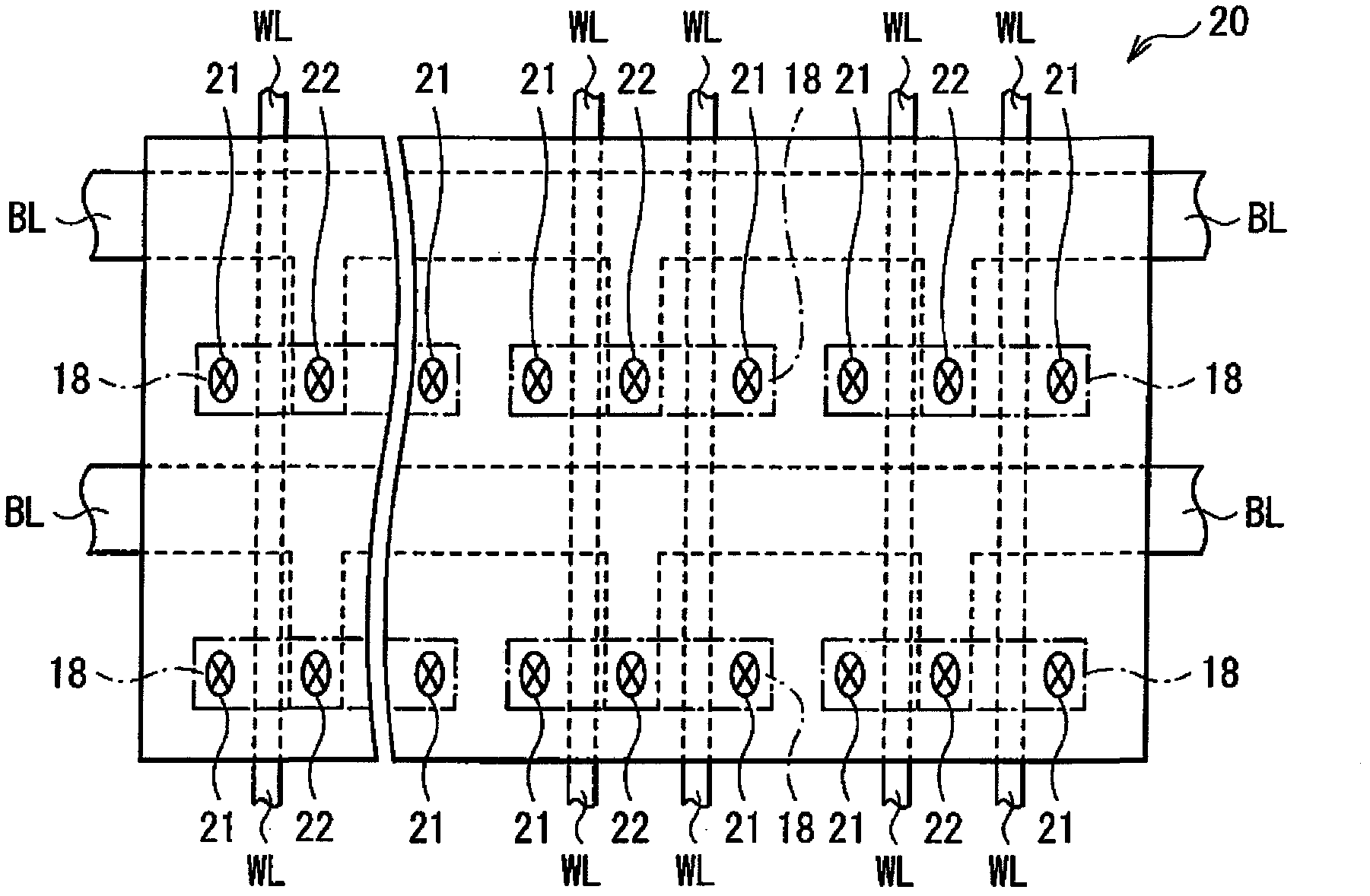

[0078] First, if figure 2 and image 3 As shown, a MOS transistor Tr is formed on a semiconductor substrate 11 . Next, an insulating layer is formed to cover the surface of the semiconductor substrate 11, the insulating layer being formed with via holes. After that, the via hole is filled with an electrode material W (tungsten) by CVD (Chemical Vapor Deposition), and the surface of the resulting via hole is ground by CMP (Chemical Mechanical Polishing). Thereafter, by repeating such processes, the plug layer 15, the metal wire layer 16, and the lower electrode 1 are formed, and then the lower electrode 1 is patterned according to the memory cell. The lower electrode 1 was formed such that its aperture portion had a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com